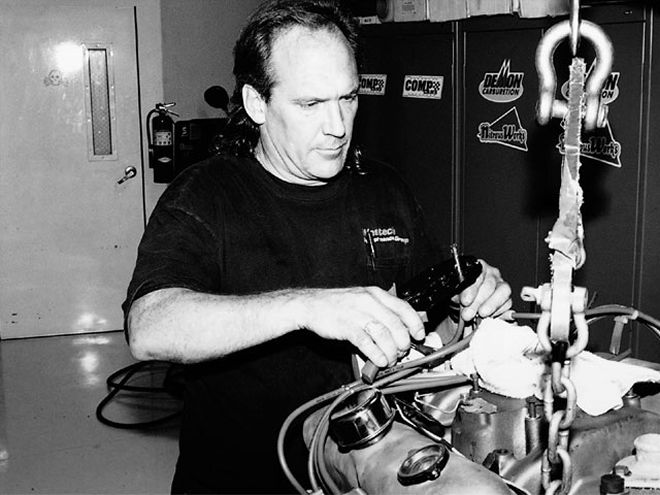

The fresh mill was carted to Westech Performance Group's dyno facilities to explore 340 Mopar power. Steve Brule of Westech cut us a set of MSD wires for our dyno session. We've found the MSD wires, unlike some other brands, hold up to dyno temperature consistently.

The fresh mill was carted to Westech Performance Group's dyno facilities to explore 340 Mopar power. Steve Brule of Westech cut us a set of MSD wires for our dyno session. We've found the MSD wires, unlike some other brands, hold up to dyno temperature consistently.

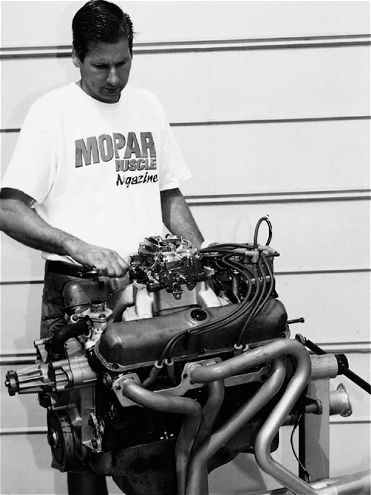

Last month, we endeavored to build a '70 340 High Performance mill as close to factory original specifications as possible, just to see how much power one of these engines would really make. The plan was to use this as a baseline, and then add a careful sprinkling of aftermarket components to see if they delivered more power for the already stout factory package. Would it work? The fresh but bone-stock 340 was loaded up, and we headed to Westech Performance Group, one of the premiere independent dyno facilities in the country, to let the 340 show its stuff.

Phase I: Stock As A Rock

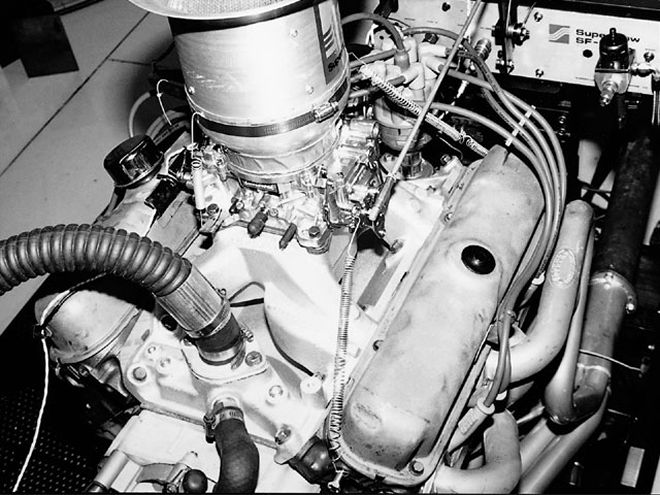

For the baseline dyno pulls, the engine was mounted to Westech's Superflow 901. At this stage, the engine was dressed out with the rare factory 340 HP exhaust manifolds, the original '70 cast-iron dual-plane intake manifold and an original 340 manual-trans Carter AVS carb. The cam was a factory 340 HP reproduction from Super Stock Industries (PAW), linked to the valves with the original stock solid pushrods and nonadjustable stamped-steel rockers. We used Chrysler's electronic ignition rather than the authentic dual point from the day.

Experience shows that the electronic and the dual point will produce the same output, if both are functioning properly. The electronic got the nod purely from reliability and consistency, and because these days they probably outnumber the dual point 100:1. The distributor was a remanufactured unit from Pep Boys, switched by a Borg Warner ECU, also from the 'Boys. A Mopar Performance wiring kit (#P3690152) and ballast resistor (#P5206436) linked the relative components. When we arrived at Westech, Steve Brule cut a fresh set of MSD wires and the 340 was ready to run.

The 340 fired on the first spin of the crank, and was given the customary 20-minute break in. We loaded the Superflow, pulled the handle, and had our baseline figures: 281.3hp at 5200 rpm and 328.5 lbs/ft at 3900 rpm. The factory rating on the 340 HP was 275hp at 5000 rpm, and 340 lbs/ft at 3200 rpm. Our 340 had topped the factory rating by a handful of horsepower, but was all well? Crunching the numbers from our baseline dyno sheet, it was clear that the mixture was too lean for peak power. Although the AVS carb was sporting the original jets, there were likely internal problems not remedied by our hasty soak and carb-kit rebuild (this carb began as one of the roughest and filthiest cores we've ever rebuilt). A jet change may have gotten us the fatter mixture the engine needed, but the jets were frozen in place with corrosion. Still, the 340 exceeded the factory power rating, and it was time to move on to Phase II.

Phase II: Edelbrock's Big Carb

Last year, Edelbrock unveiled a new 800 cfm version of its AFB carb. Similar to the AFB used as OEM equipment on some performance Mopars, the new 800 cfm Edelbrock carb is larger in terms of airflow than any of the OEM Carter AFB or AVS carbs. Those old enough will remember that it was popular to swap out the original small AVS (about 600 cfm) for the larger bore version (about 750 cfm) from the 440 Magnum. It was no secret back then that the 340 responded favorably to the increased carb capacity, suggesting that a larger carb would add to the horsepower bottom line.

At this stage, we made no other changes to our 340, and simply bolted the new Edelbrock carb to the factory iron intake. We made a partial pull to determine the air/fuel ratio, and the carb metering was close enough to make a full pull, and much nearer ideal than what we had with the stock AVS. The next pull netted us an astounding 316.9hp at 5200 rpm, and 351.3 lbs/ft of torque at 4000 rpm. That's 35.6hp and 22.8 lbs/ft from a two minute carb swap. Fact: the AVS was not performing optimally, but how many of these 30-plus-years-old carbs are? The gains with the carb swap were partially a function of old versus new, and partially a result of what Mopar tuners knew from day one-even a stock 340 responds to an increase in carb capacity. The dyno printout bore out the engine's approval of the larger mixer, with WOT manifold vacuum dropping an average of 5-10 percent, maintaining 1 inch Hg or less below 5400 rpm. With the smaller carb, 1-inch Hg internal vacuum was registered by 5100 rpm. So, volumetric efficiency went up to from 87.9 percent to 88.4 percent. The 340 was taking advantage of the increased airflow.

Phase III: Headin' For Headers

Our 340 was now making power enough to get noticed on the street, but was still exhaling through the factory-iron manifolds. These manifolds were the best the factory had to offer, and are quite scarce and expensive today. We wanted to do the modifications in a logical sequence, adding components over time like a performance fan would. The factory 340 HP manifolds hit the shelves, relieved by a fresh set of Thermal Barrier Coated Hooker "Competition Series" headers; a street A-Body header with a primary tube diameter of 151/48-inches.

Unlike tucking in a set of full-length headers on an A-Body, swapping to headers on the dyno was just a matter of wrenching for a few minutes. The advantage of individual full-length tubes was clear with the next run of the dyno-330.4hp at 5500 rpm, and 369.1 lbs/ft at 3900 rpm. The torque curve was up substantially from the bottom rpm of our pulls, right up to and past redline. The headers added power everywhere, meaning a harder launch and harder pulling up top. In fact, the peak power output on the rpm band increased by 300 rpm, while the torque peak dropped by 100 rpm, the result of an all-around fatter torque curve and a race-winning extended powerband. Bottom line? Headers work.

Phase IV: The Air Gap Advantage

The next area to look for improvements in was the ever popular intake-manifold swap. We were still running the factory 340 iron unit, but these are no slouches. At its introduction, the 340 manifold was one of the finest two-plane manifolds found on any powerplant; not too different from the conventional two-plane high-rise aftermarket manifolds. Just swapping to an aftermarket manifold will not guarantee a power increase-it takes more than just any shiny new aluminum piece.

As luck would have it, Edelbrock has just introduced their new two-plane Performer RPM Air Gap manifold for the Chrysler small-block. We already know that the relatively new Performer RPM series takes two-plane manifold power output to the next level. Edelbrock claims the RPM manifolds make top-end power approaching a single plane, with the added low-end grunt associated with a two plane. In previous testing we found it's not idle chit-chat. The new Air Gap version takes the Performer RPM concept one step further, divorcing the runners from the function of covering the intake valley, leaving an air gap between the lower valley plate and the runners. This setup, similar to Edelbrock's all-out race manifolds, cuts the manifold heat gain in the runners, providing a cooler, and thus denser charge. This 340 provides our first opportunity to put the Air Gap theory to the test.

The manifold has no provision for an exhaust crossover, which would be contrary to the very idea behind it. Generally, manifold heat from the crossover is a detriment with any aluminum manifold. The heavy iron intake was removed and the Air Gap two-plane bolted down. We liked the look of the new Edelbrock manifold, and our 340 liked the airflow, belting out a solid 354.5hp at 5100 rpm, and 384.5 lbs/ft at 4300 rpm. The manifold swap bagged a 25 horsepower gain while making more power and torque everywhere in the power curve, from the bottom to the top. Our little stock 340 cranked over 350 horsepower with basic bolt-on hot-rodding mods. With the increase in power, the useable rpm range of the engine was extended with each mod, and we let it run, increasing the test rpms with each successive mod. We wound it to 6000 rpm, and just detected the onset of valvefloat.

Phase V: Spring Time

With the usable rpm of our engine climbing steadily, we found about 5900 rpm the limit with the SSI valvesprings as installed. The spring's recommended installed height is 1.650 inches, the normal height for a small-block Mopar. In general, this is a fairly short height in a performance application, and is a handicap in production-Mopar small-block heads. We pulled a valve cover, removed a spring, and installed a height mic to see where the springs ran. Although the valve springs were set up initially at the recommended specs, we now found the springs at 1.670 inch, or about .020-inch higher. Especially with new 7-degree keepers and retainers, the keepers always tend to wedge-up as the spring loads increase. The .020 inches we gained is pretty normal, but it cost us valuable spring load as the rpm climbed.

The stock cam left plenty of room to add shims under the SSI springs, which would have added healthily to the rpm capabilities of our 340. Instead, we changed the retainer setup, going to an Engle #604LS retainer, which is dished to increase the installed height. The Engle retainers boosted the spring space available to a full 1.800 inch; room enough to swap to a much beefier spring design without worrying about coil bind. We used Engle's #993 single spring, which delivers a stout 123 pounds of seat load when installed at 1.800 inch, more than enough to control the valvetrain to very high rpm. Increasing the installed height and going to the stouter Engle springs is one of the best modifications for getting high rpm capabilities out of a small-block Mopar.

With the springs in place, the engine responded with 355.9hp at 5500 rpm, and 483.6 lbs/ft at 4400 rpm. While peak horsepower and torque were hardly changed, the 340 easily pulled to the 6300 rpm limit, 300 rpm higher than the previous 6000 rpm limit and increasing the usable hoursepower across the top of the range. We now had a 355hp, 6300-plus rpm small-block 340 with the stock heads and cam! The stock cam turned out to be a credible performer, delivering power to be reckoned with on the street, and thanks to the wide 114-degree lobe separation, we had an incredibly flat torque curve holding within 5 lbs/ft from 3500-4700 rpm. The super-flat torque curve is one of the reasons the torque's peak rpm fluctuated so much from mod to mod, since peak torque in the 1200 rpm range from the mid 3000s to the mid 4000s was within a few odd pounds per foot. Moreover, volumetric efficiency cranked to 96.4 percent, an 8.5 percent improvement over the baseline stock engine.

Phase VI: Cammin' Up

Though the 340 cam delivered the goods for power production, the technology was 35 years old. It was rated at 268/276-degrees duration; 210/220-degrees duration at .050-inch; and .429/.444-inch lift on the intake/exhaust respectively. Lobe separation was typical for the time at 114 degrees; wide by today's standards, but just the thing for an extended powerband and flat torque curve with a relatively short-duration cam in a higher-compression engine. Even an "old tech" cam sufficiently larger would have boosted power significantly, but at the expense of drivability.

We stepped up to a Comp 268 Xtreme Energy hydraulic, which features the same duration as the stock cam, but with modern faster lobe profiles. Not really a bigger cam, just a better one.

We stepped up to a Comp 268 Xtreme Energy hydraulic, which features the same duration as the stock cam, but with modern faster lobe profiles. Not really a bigger cam, just a better one.

We wanted to use a cam with similar specs, and decided on a Comp Cams Xtreme Energy 268 cam, which specs out at a similar-to-stock 268/280 duration. With much faster lobes, this cam makes 224/230 duration at .050 inch, and delivers .477/.480-inch lift. The Xtreme Energy cam is ground on a tighter 110-degree lobe separation, four cam degrees narrower than stock, which should sharpen torque generation-no loss in low-end output compared to the stock cam. Narrower lobe separation means a slightly rougher idle than the stocker, but like the stock cam, the Xtreme Energy 268 is daily-driver streetable. Although the duration is similar to stock, the increase in valve lift area from the faster-acting lobes should provide a noticeable boost in power production. Along with the cam, a new set of Comp's standard hydraulic lifters for the LA-engine was ordered: Comp #822-16.

Power surged to 391hp, along with a freight-car load of additional low-end torque. Again, more power everywhere, with no real downside. We gained over 110hp over the baseline stock 340, while gaining more than 50 lbs/ft right at the rock-bottom rpm we tested at. Who say's you have to give up bottom end to gain power up high? Using some of the best of what is available from the aftermarket, in the right combo, it's possible to substantially increase the output of even a legendary engine like the 340.

Power surged to 391hp, along with a freight-car load of additional low-end torque. Again, more power everywhere, with no real downside. We gained over 110hp over the baseline stock 340, while gaining more than 50 lbs/ft right at the rock-bottom rpm we tested at. Who say's you have to give up bottom end to gain power up high? Using some of the best of what is available from the aftermarket, in the right combo, it's possible to substantially increase the output of even a legendary engine like the 340.

The 340 cam was yanked and the Comp stick lubed and installed in its place. The installed centerline on the old cam was 112 degrees, or two degrees advanced, per the cam timing card. The Comp recommendation is advanced four degrees, putting the installed centerline at 106 degrees. We followed the instructions to the letter, degreeing-in both cams to the manufacturer's recommendations. With the engine buttoned up, it was crunch time. The 340 already belted out well over 1hp per cubic inch in a streetable package with the stock cam, so we wondered how much room there was to the upside with the Comp grind.

We gave the cam the required break-in, then pulled the handle. Wow! We had 391.6hp at 5700 rpm and a tire melting 412 lbs/ft at 3800 rpm. In fact, torque was over 400 lbs/ft from 3600-4800 rpm. We were over 110hp from stock, with nothing more than a stock-rebuild style 340 and the right combination of aftermarket parts. It's in the combination, baby! The basic 340 is capable of delivering serious power, even in very street friendly form. One of the main reasons for this is the exceptionally good flow characteristics of the production "X" heads. We already knew from previous flow tests ("Double Take" 360; Jan. 2000) what the "X" heads were capable of, so it really wasn't a shock to see the engine respond to a well thought-out modification plan. Our mildly cammed 340 in Phase VI form turned in volumetric efficiency numbers over 101 percent, and over 100 percent from 4400-5100 rpm. It took in air, and the horsepower figures proved it made good use of it.

What's next for this almost 400hp 340? The engine is going into a resto-original four-speed '70 Dart Swinger 340. The decision to run the engine stock or modified was up for grabs before this dyno experiment. With results like these, which way do you think it'll swing?

Dyno ResultsWestech Performance GroupSuperflow DynoHorsepowerRPMPhase 1Phase 2Phase 3Phase 4Phase 5Phase 63000185.2195.5199.6206.4206.2214.73200195.4206.1213.9220.7220.8229.33400208.9224.6233.0{{{240}}}.6240.5251.53600224.8238.7252.7260.8259.9275.73800236.4253.7266.6277.0276.9298.1{{{4000}}}249.5267.6280.0291.8291.8311.74200259.3278.9292.9306.0306.2327.14400265.0287.1304.3321.3321.3344.64600268.8297.2313.3335.2334.7355.94800274.7306.8321.1343.1342.5366.7{{{5000}}}278.5312.7329.1352.6350.4377.05100280.2316.9330.6354.5352.4381.35200281.3316.9330.8353.6353.6384.35400273.7314.9329.3350.8355.4386.15500273.5313.9330.4350.7355.9387.45600269.3314.5330.2350.9353.5389.45700312.7329.3348.6353.3391.65800308.8326.2347.6351.4387.2{{{6000}}}329.2353.4383.76200314.8373.7 TorqueRPMPhase 1Phase 2Phase 3Phase 4Phase 5Phase 63000324.2342.3349.5361.4361.0375.83200320.7338.3351.1362.3362.3376.43400322.7347.0359.9371.6371.5388.43600328.0348.2368.7380.4379.1402.23800326.8350.7368.4382.9382.7412.04000327.6351.3367.6383.1383.1409.34200324.3348.8366.3382.7382.9409.04400316.4342.7363.2383.5383.6411.44600306.9339.3357.7382.7382.1406.34800{{{300}}}.6335.7351.4375.4374.8401.35000292.6328.5345.7370.4368.1396.05200284.1320.1334.1357.2357.1388.15400266.2306.3320.3341.2345.6375.55600252.6295.0309.7329.1331.7365.25800279.6295.4314.8318.2350.66000288.1309.3335.86200266.7316.6Phase 1: Stock 340 baseline, Chrysler electronic ignition

Phase 2: Replace small production AVS with Edelbrock 800 CFM carb

Phase 3: Replace factory HP manifolds with Hooker 151/48-inch headers

Phase 4: Replace factory iron 340 HP intake with Edelbrock Performer RPM Air Gap

Phase 5: Replace SSI springs and retainers with Engle #604LS retainers and #993 springs

Phase 6: Replace stock 340 HP cam with Comp Xtreme Energy 268