GM has turned out a ton of variations of their venerable LS series of engines, and one block that’s easy to find and fairly cheap to buy is the 6.0L iron version. These blocks are perfect for boring out and tossing a stroker crank into. They are also a great option if you’re looking to add a little boost or nitrous at some point. Externally, they are just like their more expensive aluminum cousins, so all of the same parts like headers and drive systems will easily bolt up. The block just weighs a bit more.

Viking Performance was looking for a way to motivate their new 1969 Camaro build, and after talking with the guys at TPiS Racing they saw the cost and performance benefits of the GM iron block. After some quick math, the decision was made to poke the bores out to 4.03 inches and take the stroke to 4.00 inches. This would give them a displacement boost to 408 inches. And, as we all know, displacement is the key to making power – most notably torque.

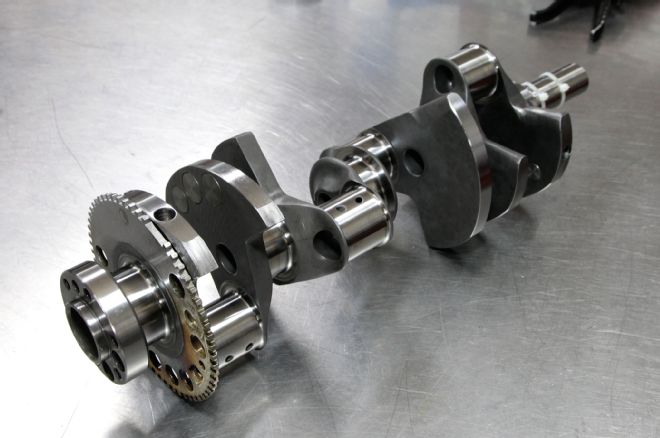

01. The heart of any engine, and a big determinant of how and where it will make power, is the crank. In this case, TPiS wanted to up the displacement of the 6.0L GM iron block to 408 cubes. To do this they sourced a 4.00-inch stroke 4340 crank from Compstar. It’s a budget-friendly crank that will easily hold up to the power they intend to make.

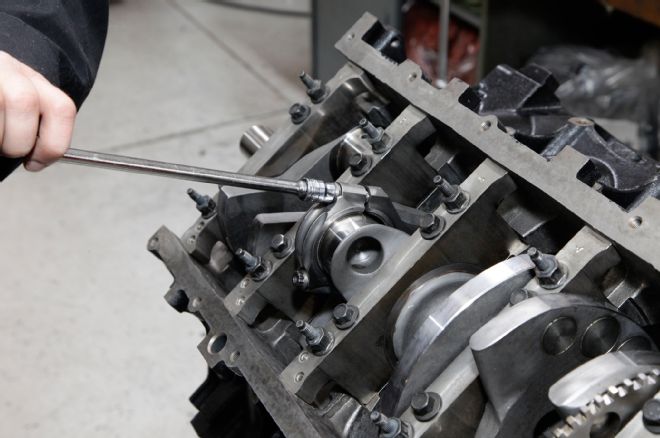

02. Once back from the machine shop, the Clevite main bearings were set in place and given a liberal coat of lube.

03. The stroker crank was then set into its new home.

04. With the main caps in place, a fresh set of GM fasteners were torqued to spec.

05. We’re big fans of pistons from Mahle. These 4.03-inch diameter slugs feature a 1.105 compression height and came fully coated.

06. The Mahle pistons were then mated to the Compstar 6.125-inch H-beam rods (PN CSC6125052A2AH). After this, the Mahle moly rings (standard tension oil rings) were file-fit and installed.

07. For heads, they went with CNC-ported RHS Pro Elite LS7 pieces (PN 54501-06STS). These heads feature a raised intake runner design that works with both stock and aftermarket LS7 intake manifolds and valvetrains. They also feature 12-degree valve angles, and the 0.220-inch raised intake runners provide a better line-of-sight into the cylinders. These came ready for a six-bolt block, but they will still work on our GM iron block.

08. The heads were installed with an ARP stud kit and GM LS7 MLS gaskets. The rockers are 1.8 ratio GM LS7 pieces fitted with COMP’s trunnion upgrade kit. The pushrods measured out at 8.2 inches. The short-block was also given a shot of purple paint to match the company colors of Viking Performance.

09. TPiS came up with these slick pieces that combine fuel rails with coil racks.

10. The ARP 2000 rod bolts (included with the rods) were then torqued to 75 ft-lb.

11. One by one, the piston/rod assemblies were slid into place using a ring compression sleeve.

12. For a camshaft, they went with a hydraulic roller deal spec’d out at 252/254 duration (at 0.050) and 0.680 lift on both the intake and exhaust. The cam had an LSA of 109.

13. The rails/racks mounted just below the custom-fabricated intake manifold.

14. And here’s the engine with 60lb fuel injectors, MSD coil packs, and billet throttle body. Now to strap it to a dyno and see what it makes.

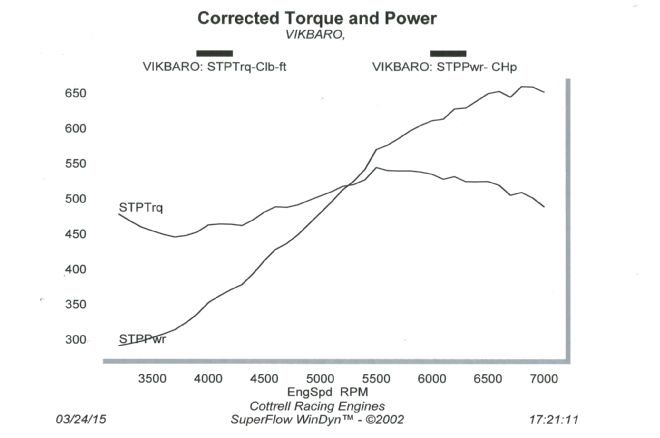

15. According to the SuperFlow dyno, the combo peaked at 660 hp at 6,900 rpm and 545 lb-ft of torque at 5,500 rpm. The massive intake made big numbers up top while sacrificing a bit of low-end grunt. At 4,000 rpm, the numbers were 353 hp and 463 lb-ft. More than enough to motivate Viking’s Camaro.