Car Craft recently built a new Chevy 383 stroker that produces nearly 460 hp. While most everything on the engine was new, the original 1969-spec starter was reused. When the engine is cold, our old starter cranks without issue, but when the engine is hot, the starter struggles. We wanted to install a new/modern-style starter, but weren't sure what attributes were really needed. Available from the aftermarket are a variety of options, including high-torque, gear-reduction, and different varieties of "mini" starters. What would be the best choice for our 10.5:1 compression ratio 383? We began our quest for knowledge with the experts at Powermaster, a company that offers a wide variety of starter styles from which to choose. We first asked them what factors one should consider when buying a starter, then moved on to discussing problems that can affect starter performance. In addition, we also spoke with American Autowire to learn of wiring issues that can affect starter operation.

Read the two Q&A sections and then follow along as Car Craft highlights aspects of the installation of a new Powermaster XS Torque starter. After installation, our new starter effortlessly cranked over the 383, whether the engine was cold or hot. Plus, the starter delivers a unique sound during operation that makes us smile each time the engine is fired up.

Q&A With Powermaster Performance

Car Craft: When choosing a new starter, at what point should you consider gear reduction?

Powermaster: There are two huge benefits to running a gear-reduction starter. The first benefit is that it can provide more torque for an engine with high compression, significant initial timing, or just any hard-to-start engine. The second benefit is the overall size of a gear-reduction starter. Tight header clearance, kick-out oil pans, or engine swaps where there just isn't any space can sometimes make a smaller-size gear-reduction starter necessary.

CC: When choosing a new starter, at what point should you consider added torque/kilowatt (kw) output?

PM: Kilowatt rating is how all electric motors are measured. The higher the kw output, the more power the motor has. That doesn't always mean that the higher the kilowatt rating, the more powerful the starter is since gear reduction is going to manipulate the end result. For instance, Powermaster's UltraTorque High Speed starter is designed for alcohol engines or engines running magnetos that need faster cranking. It has a 2.2kw rating and 3.0 hp, but is only recommend for engines with up to 15:1 compression. By comparison, the Powermaster XS Torque uses a 1.4kw, 1.8hp motor…but can crank engines with up to 18:1 compression. The different gear ratios (3.75:1 for the High Speed and 4.4:1 for the XS Torque) manipulate the power produced through the drive gear.

CC: When choosing a new starter, most people focus on the engine's compression ratio. Are there other important factors to consider?

PM: If an engine has a lot of initial ignition advance, it can make it hard for a starter to crank over an engine. With some racing engines, a timing-retard device is used during start-up. In some cases, engines with an aggressive camshaft make use of valvesprings with very high spring pressure. Such valvesprings can make it more difficult to start an engine, so a high-torque starter will be of benefit.

CC: With most 1960s/1970s starters fitted to Chevrolet muscle cars, what was the gear ratio used?

PM: Chevrolet used a starter with a 1:1 ratio. Chrysler was the first to use a gear-reduction starter as early as 1962. It's rumored that the gear-reduction concept was derived in the late 1940s.

CC: With most 1960s/1970s starters fitted to Chevrolet muscle cars, what was the approximate torque/kw output?

PM: GM built a 1.2kw direct-drive starter. Powermaster builds a new, OEM-style direct-drive starter with a high-torque, 1.4kw motor. Parts-store-sourced remanufactured starters can come with motors as low as 1 kw.

CC: Is there a difference between the amp draw of a starter when spinning freely versus actually cranking over an engine?

PM: On a workbench, a starter will draw 80 to 90 amps. However, during actual start-up of an engine, a starter will draw 250 to 350 amps.

CC: With an OEM starter, when it gets hot, it often loses much of its cranking power. What is the reason for this?

PM: A major downside to many factory starters is a heat-soak issue. For GM, they are direct-drive-type motors and they generate heat soak that drives the current demand up and pushes the efficiency down. By design, a gear-reduction starter is more efficient, so it requires less current draw, which causes less heat and you get more cranking power.

CC: Are there other items to consider that affect how well a starter operates?

PM: A starter, or any electrical item for that matter, is only as good as the power it receives. We see customers upgrading a starter to remedy problems that are actually caused by the wiring.

CC: What are the major differences between your Mastertorque and XS Torque starters?

PM: The basic design of the Mastertorque and XS Torque starters is the same. They're based on the popular Nippon Denso starters and use an all-aluminum body for lighter weight and to help resist heat soak. The aluminum-encased solenoid and starter motor allow heat to easily dissipate from the solenoid contacts and armature. Where the two starters differ is in the gear-reduction ratio. The Mastertorque starter uses a 3.25:1 ratio, while the XS Torque starter uses a 4.4:1 ratio that gives it more overall cranking torque. Both starters use Powermaster's unique Inficlock system that allows the starter to be rotated 360 degrees to clear most any obstacle.

CC: A gear-reduction starter turns the flywheel slower. However, with the extra torque/kw, does it speed up cranking of the engine so that it is similar in speed to a normal non-gear-reduction starter?

PM: Oftentimes the cranking speed difference is either non-existent or not noticeable at all. Since a high-torque starter is working so much easier to turn over the engine, it can seem as though the cranking speed is actually faster, and in some cases, it is. Powermaster offers different gear ratios to generate either more cranking torque or faster cranking for engines that are particularly difficult to start.

Q&A With American Autowire

Car Craft: What are the most common issues that affect the power wire(s) used to feed a starter?

American Autowire: Undersized cables are the most common issue that we receive phone calls on. Not only is the positive cable undersized but the negative cable is as well. With an undersized cable, the proper amount of current will not be transferred to the starter. Another issue is heat. Many vehicles are running an aftermarket exhaust system that radiates more heat onto the starter wires. Over time, increased heat will greatly degrade the starter cable that will directly affect the performance of the cable…especially during hot start-up.

CC: With regards to the starter system, how important is the ground cable in the overall mix?

AA: A poor ground can lead to many problems. For example, a bad ground can cause the vehicle to incorrectly ground through the easiest path that it can find…such as through the shifter cable. A general rule is to use a ground cable that is the same size as the positive cable. In addition, the ground cable should be mounted to a clean surface that does not have any rust, paint, or oil build-up.

CC: Are there common wiring issues when using an aftermarket starter?

AA: If your vehicle still uses an original-style points ignition system, an aftermarket high-torque starter may cause issues. The "R" terminal on a stock starter provides a 12-volt power shot to the coil when the ignition switch is turned to the start position. Many aftermarket starters eliminate the use of an R terminal that leaves no place to connect the original wire. If you simply piggyback the original R and S wires, it will cause the starter to cycle while the engine is running, which will cause serious damage to the flywheel and/or starter. At American Autowire, we created a solution that allows you to connect the R wire to the "S" terminal on the starter solenoid so that the coil will not lose the 12 volts of power delivered when cranking over the engine. Thus, order American Autowire's harness (PN 500997) to eliminate the R wire problem.

CC: Are the battery cables that American Autowire offers of better quality than the cables originally used in the 1960s/1970s?

AA: For 1955–1960 top-post battery cables, we manufacture the cables exactly to GM's OEM specifications. The cables have PVC protective insulation just as used with the original cables. Between 1961 and 1969, GM changed the battery-cable production to be a spring-ring-type battery cable. Although the American Autowire cables look the same, we have made improvements to some of the battery-cable specifications. For example, if GM sized a spring-ring battery cable at 6 gauge, we manufacture the battery cable using larger 4-gauge cable. Another improvement is if the battery cable employs a secondary lead wire, then this wire has been upgraded to a GXL cross-linked wire that provides better current flow along with higher temperature resistance. During 1969, on some vehicles, GM offered a factory option for the next generation (HD) battery that consisted of a side-post-style battery. For this battery, 6-gauge wire was used. Again, American Autowire upgrades to a 4-gauge wire along with uses GXL cross-linked wire that provides better current flow along with higher temperature resistance.

CC: How do American Autowire battery cables compare to cables commonly found at auto-parts stores?

AA: Many auto-parts stores offer lower-quality cables that are not built to the original factory specifications. One example of this is the factory spring-ring ends fitted to certain 1969-and-later GM models. In addition, most parts-store cables are offered in universal lengths fitted with universal lug ends. The battery cables offered by American Autowire are built to the original service specs using OEM-spec tooling. In addition, compared to OEM cables, most of our cables use thicker stranded wires that are constructed of a higher-quality copper. Plus, many of our battery cables have the ends dipped in solder for better current transfer and improved corrosion resistance.

Available from Powermaster are a wide variety of starters, including high-speed, high-torque, and gear-reduction (shown, right).

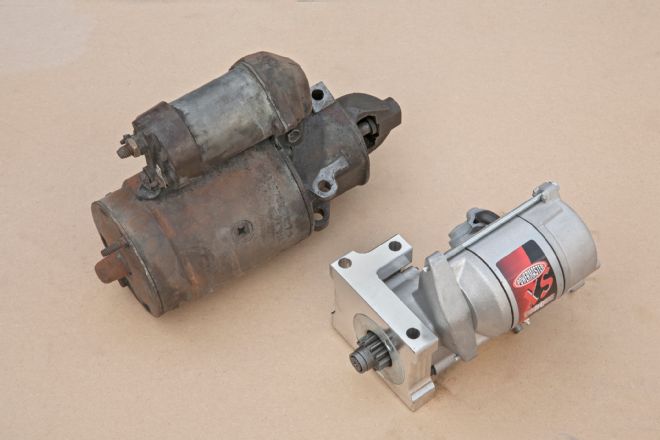

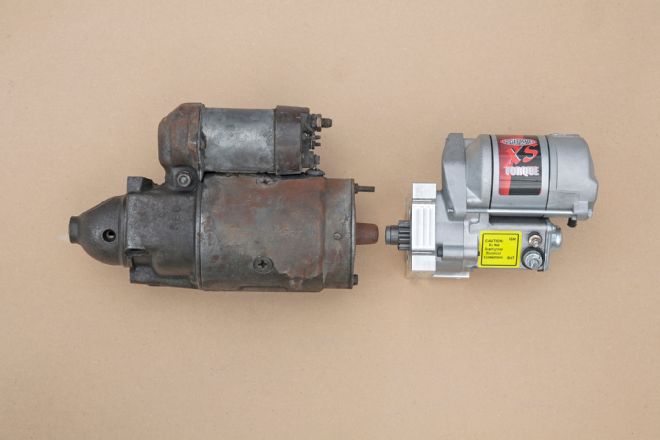

Car Craft's new 383 stroker made use of a stock GM starter. When the engine was cold, the starter would fire the engine right up. However, when the engine was hot, the starter struggled to turn over the engine.

The stock GM starter is bulky and comes dangerously close to touching the headers. As a result, excessive heat build-up within the steel case often generates heat-soak conditions that cause the starter to offer little cranking ability when hot.

In a side-by-side comparison, it is easy to see how much more compact the Powermaster starter is versus a stock GM starter.

From another angle, you can see how much smaller the Powermaster starter is. which will not only provide added clearance but also saves weight.

When comparing the weight of our stock GM starter compared to a Powermaster XS Torque starter, the difference is clear. The stock starter weighs in at a hefty 21.70 pounds, while the Powermaster starter weighs just 8.85 pounds. That is a 40.8 percent weight reduction.

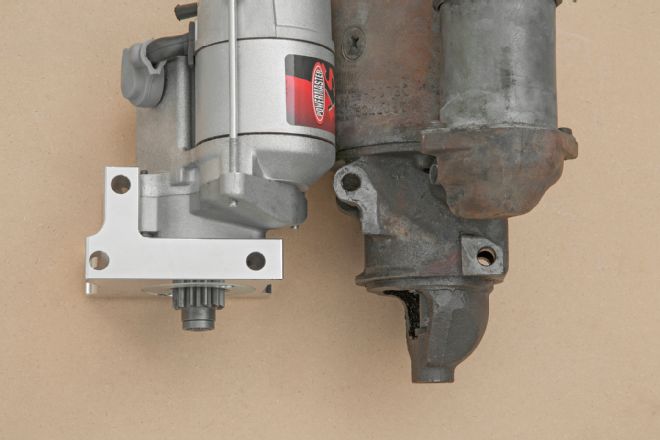

The Powermaster starter drive-gear assembly is not only more compact than that used on a stock starter but also features a straight- and staggered-bolt mounting system, which allows it to fit a wider variety of engines.

The Powermaster starter makes use of a more compact solenoid assembly with connection terminals that are much easier to access than those used on an OEM starter.

On a stock GM starter, the solenoid terminals are small and difficult to access. Usually located at the 12 o'clock position, the terminals are especially hard to reach when using aftermarket exhaust headers.

With the new Powermaster XS Torque starter bolted into place, there is radically more clearance to nearby items, including the heat-radiating aftermarket exhaust headers.

American Autowire's starter wires not only feature better quality copper wire and are larger gauge but also feature solder-dipped ends that generate better current transfer—and significantly improved corrosion resistance.

While an aftermarket starter offers great advantages over OEM, if the power supply isn't adequate, then problems will still exist. Thus, we upgraded to new power and ground wires from American Autowire. The wires are larger gauge and are constructed of higher-quality copper wire to better transfer electrical current.