Way before we became accustomed to buying fuel at self-service convenience stores, many a young gearhead worked in a service station pumping gas for their patrons. Those who remember driving into a service station and running over a hose that rang a bell announcing your presence, then watched as a kid filled your car with gas, washed the windows, and checked under the hood using the red rag that usually dangled from a rear pant’s pocket have experienced a real service station—or maybe you were the kid with the rag.

Back then, a big part of the service station business was performing periodic maintenance—changing the oil and filter, lubricating the chassis, and checking all the fluid levels, including the battery. The battery was something that had to be looked after regularly. During the normal discharge and charging wet cell automotive batteries would often lose water and it had to be replaced—if the electrolyte level dropped too low the lead plates were exposed to air and they could be damaged. But many things have changed since those days, including service stations and how batteries are maintained.

Battery Basics

Automotive batteries all work pretty much the same: Each compartment, or cell, produces 2.1 V, as a result a 6V battery has three cells and produces 6.3 V at full charge while a 12V battery has six cells and produces 12.6 V at full charge. In each cell are groups of positive and negative lead plates with separators in-between to prevent them from shorting out. The lead plates and separators are submerged in a material called electrolyte. When a load is placed on the battery a chemical reaction takes place between the plates and the electrolyte that releases electrons to supply required electrical energy. As the battery discharges the lead on the plates is altered and the electrolyte gets weaker. The result is the battery runs down, or goes dead. As it is recharged, the process is reversed and the composition of the plates and sulfuric acid level of the electrolyte are restored.

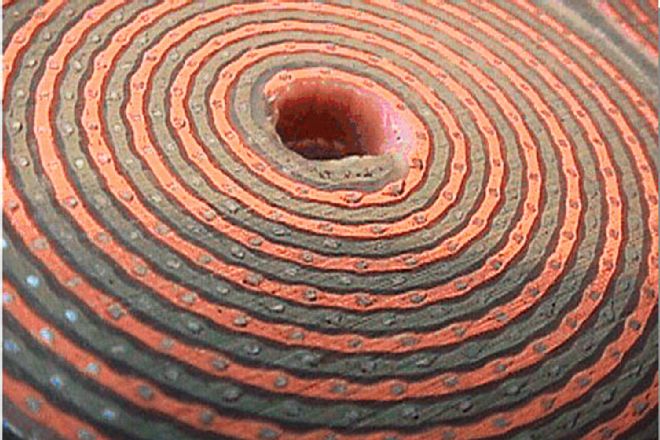

This is a closeup of Optima’s spiral wound construction; it gives their batteries that unique “six-pack” look.

This is a closeup of Optima’s spiral wound construction; it gives their batteries that unique “six-pack” look.

One of the reasons often given for battery failures is sulfation. During the normal process of discharging lead sulfate forms on the plates, then during recharging it reverts to lead, lead dioxide, and sulfuric acid. But while sulfation is part of the discharging and recharging process, when lead/acid batteries are left in a low state of charge for extended periods the sulfate crystals grow larger and inhibit the recharging process. Batteries that sit unused for prolonged periods, such as those in street rods that may be parked for the winter, are particularly susceptible to damage by sulfation.

Battery Construction

Automotive batteries fall into two separate categories, flooded cell and VRLA (valve-regulated lead–acid battery) or the sealed type.

Odyssey AGM batteries are available for auto; LTV; commercial; marine and power sports applications; and all are considered deep-cycle.

Odyssey AGM batteries are available for auto; LTV; commercial; marine and power sports applications; and all are considered deep-cycle.

Conventional flooded batteries can be identified by the removable caps on each cell and the liquid electrolyte inside each of those cells. Care must be exercised with this type of battery as any spilled electrolyte can cause severe burns to those coming in contact with it, as well as corrosion to any metal it is spilled on. In addition, during charging hydrogen gas is created, which is explosive. The odor of rotten eggs or dampness on the top of the battery case indicates the presence of hydrogen gas and any spark can cause the battery to explode. To help prevent accidents, always disconnect the negative cable first—if the wrench being used hits metal there won’t be a spark as the terminal is already grounded. Once the negative cable is removed, disconnect the positive—if the wrench hits metal there won’t be a spark because the ground has been removed and there isn’t a complete circuit. When installing a battery, do the reverse—tighten the positive first (no ground, no spark) then the negative (already grounded, no potential for spark).

A variation of the flooded-cell batteries is the maintenance-free variety. Basically these batteries have more fluid capacity above the plates so adding water is not supposed to be necessary. Some maintenance-free batteries are sealed; others do have removable caps in the event water does have to be added.

Sealed VRLA come in two forms, the gel type or the Absorbed Glass Mat, or AGM. While these batteries are described as being sealed, they do have pressure relief valve to allow hydrogen gas to escape if they are overcharged.

As the name implies, gel batteries have electrolyte that has been mixed with silica dust to thicken it and make it into a paste or gel. The description of a battery as being an Absorbed Glass Mat is kind of a giveaway too. AGM batteries use separators made from fine strands of glass fibers that hold electrolytes like a sponge. The plates in an AGM battery may be flat while others are bent or rolled.

Odyssey uses AGM technology to contain acid; the conventional outward appearance is the result of using densely packed; flat plates.

Odyssey uses AGM technology to contain acid; the conventional outward appearance is the result of using densely packed; flat plates.

Gel and AGM batteries have similar traits—they’re non-spillable, may be mounted in any position (upside down is not recommended), have low self-discharge rates, and they can be mounted in spaces with limited ventilation. But despite their similarities, there are also significant differences between the two. Gel batteries do not tolerate high amp discharge or recharging—either can cause voids in the gel, which allows the plates to corrode, which leads to premature failure. AGM batteries produce more power than a gel of the same size, and they’re less expensive.

AGM batteries come in three configurations. As Scott Parkhurst, former tech editor of Popular Hot Rodding magazine, explains them: “Starting Lighting Ignition (SLI) batteries excel in high starting energy output, where only light surface cycling takes place. SLI batteries are typically used for short bursts of power, such as starting an engine or running light electrical loads. SLI batteries also supply extra power necessary when the vehicle’s electrical load exceeds the supply from the charging system and act as a voltage stabilizer in the electrical system, evening out voltage spikes and preventing them from damaging other components in the electrical system.

Deep-cycle batteries are designed for applications that require deep, repetitive amperage drain, like trolling motors, electric wheelchairs, RV house power, and in-start applications where the system load exceeds the alternator output for short durations. When the engine idles and the alternator output drops, the deep-cycle battery can continue to support the load with high current and then recharge fast when the engine speed and alternator output increases.

For owners/builders of modern high-tech rods with EFI and computer-controlled transmissions, high-intensity lighting, modern stereo and/or video systems, electric air compressors (for air suspension systems), or any electrical systems that are regularly functioned when the car isn’t running, deep-cycle batteries are the best option and they will still function perfectly as starting batteries.

Marine/RV batteries are also offered in both SLI and deep-cycle configurations. But as boats and RVs can have different cable mount and sizing options, the Marine batteries are designed to accommodate them.”

Getting All Charged Up

Optima’s Digital 1200 charger can be used with AGM and flooded batteries. It also features an LCD display for charging; maintaining; and fault mode indication and a gauge that displays battery charging and fill rate. It includes an LED work light with DC charging clamps; quick set selections for battery type. It even has USB charging for iPads; iPhones; and other devices.

Optima’s Digital 1200 charger can be used with AGM and flooded batteries. It also features an LCD display for charging; maintaining; and fault mode indication and a gauge that displays battery charging and fill rate. It includes an LED work light with DC charging clamps; quick set selections for battery type. It even has USB charging for iPads; iPhones; and other devices.

Like most stories, there are two sides to this one. Although AGM batteries offer a host of advantages over the flooded type, they are extremely sensitive to overcharging. AGMs should never be recharged with a “conventional” battery charger as they may put out 16 to 18 V, which was often necessary to charge flooded batteries with higher resistance. AGM batteries have much lower internal resistance and as a result should never be charged at more than 14.7 V.

The Digital 400 from Optima is a maintainer and charger that is capable of recovering deeply discharged AGM and flooded batteries. It includes a charging gauge with an LCD display and has spark-free connection technology.

The Digital 400 from Optima is a maintainer and charger that is capable of recovering deeply discharged AGM and flooded batteries. It includes a charging gauge with an LCD display and has spark-free connection technology.

When flooded batteries are overcharged, hydrogen gas is created, which escapes from the vented cells. The cure is to simply add distilled water to restore the level of electrolytes. When an AGM battery is overcharged heat is created and while they do not have vents, the battery will expel gas through the safety release valve (this is normally accompanied by a hissing sound). Once that happens there is no practical way to replace the water and premature battery failure results.

Odyssey offers a variety of battery chargers with outputs ranging from 6 to 50 amps. All have three-phase charging: bulk to get the battery to 80 percent; absorption to finish off the charge; and float to keep the battery topped off.

Odyssey offers a variety of battery chargers with outputs ranging from 6 to 50 amps. All have three-phase charging: bulk to get the battery to 80 percent; absorption to finish off the charge; and float to keep the battery topped off.

Eastwood’s Battery Sustainer has a two-amp output for charging and maintaining flooded; AGM; and gel batteries. The microprocessor-controlled technology will recharge dead batteries and cut off when fully charged; it will also maintain stored batteries in peak condition.

Eastwood’s Battery Sustainer has a two-amp output for charging and maintaining flooded; AGM; and gel batteries. The microprocessor-controlled technology will recharge dead batteries and cut off when fully charged; it will also maintain stored batteries in peak condition.

Another peculiarity of AGMs is the difficulty recharging them when the voltage drops below 10.5 V. Most conventional battery chargers have the capability to sense low resistance that could be a result of a shorted, or bad cell—these chargers interpret the low resistance of a discharged AGM as a fault and as a result, won’t charge.

While it is true a conventional battery charger can be “fooled” by connecting a discharged AGM in parallel with one that’s charged (the charger reads the resistance of the good battery), the process has to be monitored closely to prevent overcharging.

Considering the fact that AGM batteries are becoming common, there’s not much in the way of an argument for not having the proper charger. In a perfect world batteries would always stay charged, but the truth is if your street rod sits for an extended period of time the battery is losing juice. The proper battery maintainer/charger can keep an AGM battery in shape to provide all the performance it’s capable of when you need it. Think of them as the best in re-volting developments.