Time for Project Nova to get an eight-point rollbar. We started with an Art Morrison Enterprises general-purpose eight-point kit with optional rear seat retaining bars, a swing-out side bar kit, and Corbeau three-point harnesses. Outlaw Motorsports stitched it all together with a Millermatic 211 MIG welder.

Time for Project Nova to get an eight-point rollbar. We started with an Art Morrison Enterprises general-purpose eight-point kit with optional rear seat retaining bars, a swing-out side bar kit, and Corbeau three-point harnesses. Outlaw Motorsports stitched it all together with a Millermatic 211 MIG welder.

Deciding to go with a weld-in rollbar is a major turning point in building any street car. There’s a mental block that says, “Hey, this is a race car,” when you still want it to function as a street car. The choice to do a rollbar, however, is made a lot easier if you know that not only will you be safer, but your ride will be much stiffer, and as a result, will feel much lighter. Why? Because a stiff chassis is one that responds quicker, moves sooner, and preserves the intended suspension geometry better. It’s also why weld-in beats bolt on every time.

Outlaw’s Ron Aschtgen used a hydraulic tubing bender for several operations, but here he’s narrowing the AME main hoop to fit inside the Nova cabin. AME’s generic kit uses 1¾-inch diameter .134-inch-thick mild steel tubing throughout for conformity to NHRA specs.

Outlaw’s Ron Aschtgen used a hydraulic tubing bender for several operations, but here he’s narrowing the AME main hoop to fit inside the Nova cabin. AME’s generic kit uses 1¾-inch diameter .134-inch-thick mild steel tubing throughout for conformity to NHRA specs.

For Project Nova, we reached out to Art Morrison Enterprises for one of their eight-point mild steel rollbar kits. AME is a major player for chassis, rollcages, and rollbars, and has for decades been synonymous with cutting-edge chassis design and safety. Our general-use AME eight-point kit is a time-tested design, offering the protection and stiffness we desire while fulfilling the necessary safety requirement. We also supplemented this kit with the optional rear seat retention mod; this places the rear bars over the top of the rear seat and through the package tray instead of through the seat back. We’d be able to keep our rear seats for that rare situation when we still need to use it. Street use being the primary function of this ’68 Nova, we also ordered a Morrison swing-out side bar kit. This retains the driver-side bar in place for safety on the track, while allowing it to swing out—or be removed entirely—for use on the highway. Suddenly, a race-only deal has become quite street friendly. A win-win situation for sure.

With any rollbar installation, consideration must be given to seating and harnesses. We had already installed a beautiful and supportive pair of Corbeau Sport seats in black vinyl ($299 each), so it was only natural to choose a matching pair of black Corbeau three-point dual-release harnesses. The “dual release” refers to the extra shoulder strap latch, which can be disconnected from behind for stowage, rear seat access, or maintenance. The Corbeau seat/harness combo is the perfect choice for modernized muscle that sees aggressive street and track use. It feels great, looks good, and won’t break your bank.

The main hoop attaches to the Nova’s rocker channels via .125-inch-thick 6x6 steel plates that must be formed over the sheetmetal. Note: The surface has been prepped with a grinder for welding.

The main hoop attaches to the Nova’s rocker channels via .125-inch-thick 6x6 steel plates that must be formed over the sheetmetal. Note: The surface has been prepped with a grinder for welding.

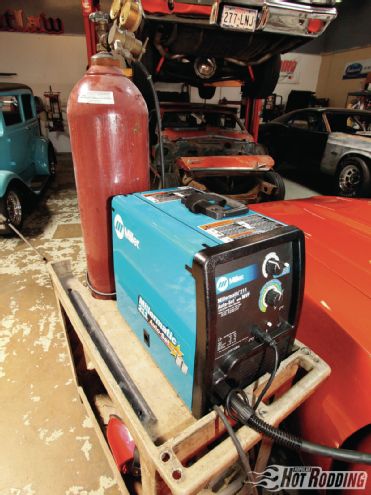

Of course, doing a truly safe weld-in rollbar depends on having a competent MIG welder—which we have in the form of a Millermatic 211 with Auto-Set. The Millermatic 211 was designed from the outset for serious hobbyists and professionals; the features we love the most are its ability to operate on either 120 or 230 V, and to take the guesswork out of control setup. With Miller’s Auto-Set, all you do is set your filler wire thickness and your material thickness via two dials. The Millermatic 211 will set the wire feed speed and amperage automatically for a perfect weld every time. And the Smooth-Start feature provides a spatter-free start too.

Putting it all together for us was Ron Aschtgen of Outlaw Motorsports in Riverside, California. Outlaw does a lot of rollbar and rollcage installations, as well as full chassis fabrication, and this job was right in their wheelhouse. For a job like ours, Aschtgen typically charges $750 for the labor—which in our case includes doing the swing-out bar, mounting the harnesses, and painting the rollbar. Total time on our eight-point Morrison kit was 12 hours over a two-day period. We are extremely pleased with Aschtgen’s handiwork, and we will have no qualms tossing this Nova around on the track.

Our MIG welder of choice: Miller Electric’s Millermatic 211 with Auto-Set. We had it loaded with thin .030-gauge filler wire because we were welding to thin sheetmetal. The 211 has a multi-voltage plug (MVP) allowing us to run it on 230 or 120 V.

Our MIG welder of choice: Miller Electric’s Millermatic 211 with Auto-Set. We had it loaded with thin .030-gauge filler wire because we were welding to thin sheetmetal. The 211 has a multi-voltage plug (MVP) allowing us to run it on 230 or 120 V.

Take a look at how Outlaw tailored the AME kit for our ’68 Nova, then go over to www.YouTube.com/PopularHotRodding and check out the videos “Rollbar Installation” Parts 1 and 2 to get the inside scoop on how Aschtgen got the job done!

What To Get Description: Source: PN: Cost: 8-point rollbar kit AME 20203000 $215 Rear seat retention upgrade AME 20211200 $45 Door swing-out kit AME 20240000 $65 3-point double release harness Corbeau 43201B $95 ea. Extreme Chassis Black aerosol Eastwood 11175Z $19.99 Millermatic 211 Auto-Set MIG Miller Electric 907422 $1,317