Though not quite an oxymoron, we should preface this story about our ’67 Cougar by saying that street friendly is a relative term here. Max Effort’s ethos through and through is pushing a street-legal muscle car as far as possible on the road course, and to make that a reality we need a ’cage that’s designed to function on several levels.

First and foremost is safety; building a car with high levels of performance potential necessitates planning ahead for the worst possible outcome. If something goes wrong, we want to walk away. Or at least limp.

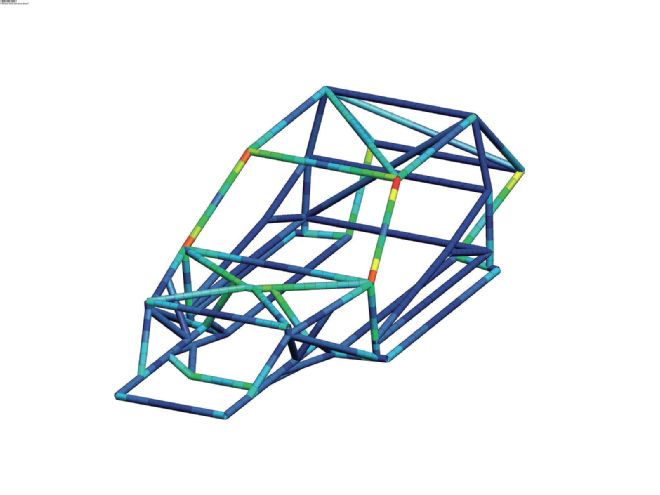

This CAD rendering by Filip Trojanek at CorteX Racing looks like a design for a full tube-chassis car (and it could be), but it’s actually the model for Max Effort’s rollcage. Some of the bars represent structure to be built while others stand in for unibody structure already in the car. The design was shown to increase the rigidity of the Cougar/Mustang body by 500 percent. Essentially, once the ’cage is in the body, it just becomes decoration.

This CAD rendering by Filip Trojanek at CorteX Racing looks like a design for a full tube-chassis car (and it could be), but it’s actually the model for Max Effort’s rollcage. Some of the bars represent structure to be built while others stand in for unibody structure already in the car. The design was shown to increase the rigidity of the Cougar/Mustang body by 500 percent. Essentially, once the ’cage is in the body, it just becomes decoration.

To extract every ounce of capability out of our CorteX Racing suspension system, we also need to create a ’cage that is designed to make our unibody chassis as rigid as possible. Flex and twist are your enemies when you’re generating high g-forces, as they literally change the geometry of the chassis. Factory unibodies function a bit like monocoques by using the panels and the tub of the car as structure, but are typically quite weak in terms of deflection, especially in vintage cars. What we want is a ’cage that essentially becomes the load-bearing skeleton of the car.

On the street side, we want to do all of the aforementioned without making ingress and egress too much of a contortion act. The real trick to making a true competition ’cage feel more streetable, though, is to minimize the imposing look and feel by integrating it so well into the interior that it looks almost graceful and natural, and less pure race. That’s no easy task since it requires balancing safety with style, but fortunately for us that’s a skill something Ryan Kertz at Kertz Fabrication excels at.

Kertz is a high-level race car fabricator, so strength and safety are always paramount in his plans for any rollcage. Nevertheless, he’s also one of the few such metal benders who also believes in creating a ’cage that feels custom tailored to a car rather than just assembled for strength. What’s the difference? Organic flow. Any number of ’cage configurations can be strong, but there are certain guidelines that must be followed to create one that feels like it was intended just for a particular car.

Ideally we should have the correct seat and steering column installed, but since we’re planning to build in a lot of adjustability for different drivers it won’t be much of an issue. For now we’re sitting on a block to approximate height and driving position while Kertz takes measurements. It also helps if you make engine sounds.

Ideally we should have the correct seat and steering column installed, but since we’re planning to build in a lot of adjustability for different drivers it won’t be much of an issue. For now we’re sitting on a block to approximate height and driving position while Kertz takes measurements. It also helps if you make engine sounds.

The good news is that it’s all stuff that can be learned and applied to any ’cage, and Kertz has agreed to show us some of his tips and tricks for installing a totally sano structure. While this particular ’cage for Max Effort is more than most rodders will need or perhaps want, the same concepts will apply to pretty much any endeavor. If you’re looking for a trustworthy place to build a beautiful and functional ’cage for your ride, give Kertz a call. Trust us; it would be worth the effort to get your car to his shop at Infineon Raceway.