Rewiring your classic truck, or any vehicle, can be a daunting task. That spaghetti-like mess of wires can really be overwhelming. Here's a few tricks I have used over the years to rewire projects from scratch.

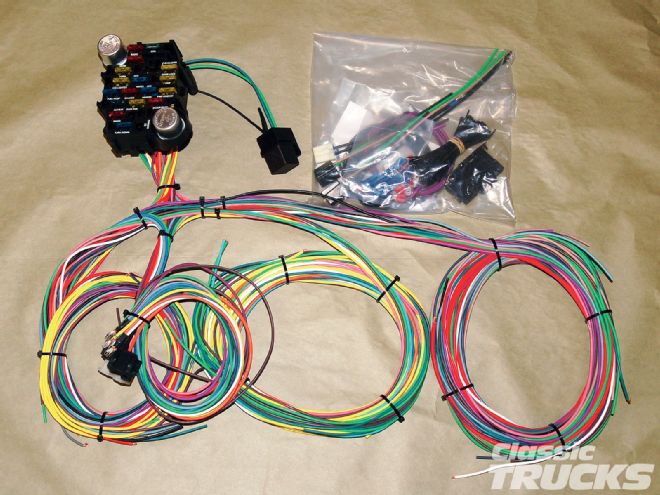

First, choose an aftermarket harness to install. Quite a few are out there, and they all work well. My personal favorite is one from EZ Wiring. Their 18- or 21-circuit preterminated panels work real well in both trucks and cars. The circuits include those for dome lights, A/C, third brake lights, reverse lights, cruise control, cigar lighter, power windows, power door locks, electric fan, and more. I prefer EZ Wiring kits over the others because the printed names on each wire are just that, the name of what the wire does. Other manufacturers also print the circuit the wire applies to, which can be confusing and hard to read on some smaller-gauged wires. EZ Wiring kits are offered in a GM color-coded format that is easy to get used to. Having done so many over the years, I can sort them out by color and not so much by the words printed on the wires. Though, the names of the wires printed on each one make the wiring job so much simpler. A booklet is also included that has the popular Ford, GM, and Chrysler charging and turn signal circuits drawn out as well as basic light, ignition, and dash circuits. Plus they have some helpful hints listed.

If you are wiring a car that includes a fuel-injected engine and you are using a harness from the injection manufacturer or a kit from suppliers like Street and Performance or Howell, I have found it works well to run all the primary wiring from your fuse panel kit and then install the fuel-injection harness. Laying the fuel-injection harness on the floor and familiarizing yourself with it and where the hot and ignition feeds are in relation to where you need them is a big help. Some kits also have relays and small fuse blocks that need to be mounted as well and with a little preplanning they will integrate right in with the fuse panel mounting and primary looms. Mounting of the computer to be used is probably the hardest part of most kits. They have those so well designed that they really are plug-and-play. Plug in all the sensor wiring on the engine, mount a couple of relays and a fuse panel for the injectors, and hook up a couple of hots and grounds, and you're pretty much done.

The next thing to think about is the mounting of the fuse panel, relays, and additional control units like MSD ignition boxes, electric fan control, and others. In the F-100s I've built over the years, we didn't want any bolts or screws going through the firewall, so I make up a 1x1-inch square tube with brackets on each end to bolt the tube to the sides of a couple of interior braces at the cowl section of the truck directly behind the firewall. This bar also mounts the A/C unit on the passenger side. A panel of aluminum or sheet steel is cut to around 15 by 7 inches and spot-welded or countersunk screwed to the tube. I've even welded T-nuts to the firewall in the mock-up stage and used them to retain a piece of 1/2-inch-thick plywood that itself has T-nuts in to mount the panel and A/C. This can be quite a pain if you want to later add mounting points for something else. For me the 1x1-inch square tube worked the best.

After getting your mounting place decided upon and installed, start the wiring job by mounting the panel first. Look at where the wires need to go in relation to what they are for. A little preplanning here goes a long way in the finished job. Do you want the wires to be hidden from view when installed? Where can you route them best to get them to do what they need to do. For the F-100s and most any other car I've wired, they all basically go the same route. From the fuse panel, my engine wiring goes along the 1x1-inch tube to the center of the vehicle and then drops down through a 1 1/4-inch grommeted hole at the top of the tranny cover on the passenger side. This puts the wire loom at the back of the engine with the wiring coming down the engine on the passenger side and wrapping around the front of the engine to hook up the alternator, A/C, distributor, temp sender, and others. The starter wires drop down to the starter and in the case of the F100s, the battery hots are routed to the battery box under the passenger floor. With the front seat removed, I sit on the driver side and cut the coiled up looms apart one at a time. Usually first is the looms for the front and rear wiring. I roll out the looms one at a time on the floor next to the truck and pull out the wires that are going some other place. Then using some tape I tape the loose ends of the wire loom together so the loom is easier to feed through the body and grommeted holes. Then I do the engine wires and route them over to and through the hole at the bottom of the firewall. Last is the dash wiring, which I route along the bottom of the dash. Loom the wires together with a few zip ties and lay them on the inside of the dash. Decide where your switches are going to be and stub out the wires for each switch from the loom.

The front and rear wiring looms are routed over to the driver-side cowl area just in front of the driver's door. They are hidden by the driver-side kick panel when installed and exit out the bottom of the cab right under the front cab mount. They then run across the front cab mount and split off to the front and rear on the inside of the framerail. If the customer is using a reproduction chassis that is fully boxed then I hole-saw the side of the rail and route my wiring inside the rails for as far as I can. Small holes are drilled and grommeted to pop wires out at places like the brake light switch, electric fuel pump (if on the rail), and such.

On a stock chassis the rear wire loom pretty much follows the brake lines and is zip-tied to it for mounting, or you could drill and mount clamps along the inside of the framerail to attach the loom. The front wire loom with the lights, fan, and horn wires is routed up the wheel side of the inner fender and attached to the bolts that mount the inner fender to the fender. I make small tabs that bolt to the inner fender bolts and then the loom is zip-tied to the tabs. The loom drops down from the top of the inner fender at the air deflector shields and splits off there for the driver-side headlights and turn signal. Then the loom is run across the front of the bottom of the radiator and over to the passenger side where it goes up the air deflector shield and in to the passenger-side headlight. I zip-tie the loom to the metal brace supports on the backside of the gravel pan. Always start from the fuse panel, working your looms out to where they are going to end. Secure the looms along the way as you run them, then hook up whatever the wires are going to last.

Testing of the lights, fans, and others, for the proper wiring of them is easy with a 12 or 14V battery from your battery-powered drill. You can test electric fan direction, turn and taillights and hook the wires up right the first time. I've also used an automotive battery charger to test with.

The dome light circuit provided with the EZ Wiring panel is a white, battery hot wire. I run a black 18-gauge wire as a ground from the door switches up to the dome light with the white wire. So now the door switches are breaking a ground to turn the light on and off. This works well with the aftermarket headlight switches that have a grounding operation when the knob is turned all the way to the left to turn the dome on. Starting at the passenger side, run a black wire from ground to the door switch, from the door switch to the driver-side door switch, with an extra leg to the headlight switch, and up to the light. Also run a wire from ground to the driver door switch. The pigtail contact in the stock dome is one contact type and is changed to a two contact style. Part stores sell a double contact pigtail that fits right in. Then use a double contact bulb like No. 98. You can still use the stock on/off switch at the dome light if you like by hooking the black ground wire from the door switches and one of the dome light socket leads together. Then connect them to one side of the on/off switch and connect a ground wire to the other side of the switch.

Running wires into the doors is another tricky situation made easier by companies like The Glass House. Mike makes a bitchin door conduit product that has two machined aluminum bezels that retain a spring in which to run the wires. Hole-sawing the doorjamb for them is critical as the alignment of the two must be perfect for the spring to smoothly slide in and out when opening and closing the door. When installed they are a real clean way to get those power window and door lock wires into the doors.

Electric fan control for the engine fan can be controlled in many ways. My personal favorite is a controller made by Hotronics. It comes with a two-prong pipe threaded sensor that is available in 3/8- or 1/2-inch pipe thread sizing. It is installed by the upper radiator hose, in the intake or thermostat housing, and wired to a control box that is mounted underdash. The sensors have several heat ranges available that turn the fan on and off. The 180-degree works very well. You can also add a relay in the circuit to turn the fan on when the A/C is on. Remember to change the fuse in the panel to a 30-amp replacing the 20-amp that comes in the wiring kit. I have used them for over 15 years and never had a problem with one. Greg Schlup, the owner of Hotronics has developed quite a few neat electrical controlling devices for hot rods.

Mid Fifty F-100 Parts, in Golden Valley, Arizona, is your one-stop shop for anything having to do with '50s F-100s. Sy Miller and her all girl crew are the most knowledgeable and helpful group you've ever dealt with. Miller has spent the last 10 years or so developing reproduction parts to fit F-100s from end to end. You could build an entire truck from her catalog. In this wiring job we used her repo gauges to rebuild the stock cluster. It started out with just idiot lights, but with her new gauges it was easily converted. They simply screw right in to the stock openings. She also offers rebuilt speedo heads so your new F-100 will have an odometer that reads 00000 to start with. A new chrome bezel completes the rebuild of the gauge insert.

The gauges come with the required sending units. The fuel sender is universal and must be cut to fit the depth of the tank you're running.

She offers all-new switches for your truck's electrical needs-ignition, headlight, and door switches for dome lights, dimmer switches, and more. The whole wiper assembly is also available, from the wiper blades to the switch. The complete kit bolts in and works great.

This truck is also getting some power one-piece side windows and the window channel and glass kit came from Mid Fifty's also. Nu-Relics supplied the power motors, which are basically a stock kind of setup with power motors on them. They bolt into the stock regulator mounting holes in the door and work well. If I have one complaint it is that the whole regulator assembly covers the area where I like to have the window switches mounted. So instead they are going to be mounted in the opening of the door hinge bolt pocket. They could also be mounted in the kick panels or under the center of the dash, or if you're running an overhead console for your stereo, they can be mounted there too. The power window wiring was run at the same time as the rest of the wiring.

Since we're using a Classic Performance Products tilt steering column in this truck and these columns, like the ididit's, don't provide any way to mount a neutral safety switch to them, CPP has a neat add-on type that is billed as a neutral safety switch but actually is more of a brake safety switch. It is a relay that is wired in with a brake light switch installed in the brake line and used to trigger a relay to allow the vehicle to be started. In other words, the engine won't start unless your foot is pressing on the brake pedal. This way, even if the trans happens to be in Drive or Reverse, you're ready to apply further pressure and stop any movement before it gets away from you. It's better than nothing at all. It also doubles as an antitheft device since what thief is going to think of pressing the brake pedal to start the car.

These wiring kits also include an ignition and battery hot for the stereo, a wire for a power antenna, a wire for a trunk light, and a wire for a third brake light, which would need its location decided on when you run the wiring. It could go in the back of the cab sheetmetal, in the rear window, or as we often do, at the rear of the truck on the license plate frame as part of the license plate light and frame.

Up front the grille gets mounted loosely and the park light assemblies are installed. I say mount the grille loosely because you usually have to lift it up to get the stainless park light covers to fit. The wires are run into the headlight bucket area and hooked up. Be sure to check which wire is which, turn or park, with a power source so you don't have to remove the headlight assembly to change them. I take a piece of 7/64-inch windshield washer hose and slit it down the side and install it on the bottom of the park light stainless trim cover. It keeps the sharp edge from eating up the paint as you install them. Those trim pieces are a real tight fit and new paint is always looking for ways to end up scratched.

After you've got the whole system hooked up and it's time for the first check, I head over to the battery location and hook up the positive cable. Make sure all your switches are off and remove the dome light fuse. Then I touch the negative cable to the post. You shouldn't see any spark when they touch. Go ahead and connect the cable to the post and turn the key on. Check the dash gauge operation, they should come up off the posts or move to the lowest setting on the gauge. Turn the headlights on, check the high/low beam switch and indicator light. Turn the turn signals on and check their operation and the indicator lights. Then the wipers and so on. Turn the key and fire up the engine, if you're at that point in the build. Don't forget to push the brake pedal down to start the engine if you've installed the brake safety switch!

If you should end up with a dead battery and you need to find the cause, like a draw in the system. First remove the dome light fuse because you'll be working with the doors open. Disconnect the negative cable and hook a test light clamp to the negative battery post. Touch the test light probe to the cable clamp and if the light lights, then you have a draw. Now just start removing fuses and unplugging added accessories until the light goes off. Then you found your draw. Common draws are the relays in remote door opening kits, and horn wires at the steering column going to ground. Clicking relays when the battery cables are connected to the battery are a good place to start looking first for a draw.

That about finishes the wiring installation-if you're smart you won't cut out any of the extra wires in the loom as you install it. Simply leave them zip-tied in the loom that runs along the bottom of the dash, and if you need that circuit or one for some addition you've got an ignition or battery hot wire ready to use.