We don't think anyone will argue that even with perfect paint, a restoration doesn't really shine if the trim still looks beat up. We've long been able to repair or replace most anything that's painted, but chromed, stainless, and aluminum trim is a different story. Their shiny surfaces are as unforgiving to flaws as some of the show judges out there. If it's not perfect, someone will spot it. So, what are you to do?

You can't run down to your local dealer and buy new parts anymore. You already know that you can't buff it out. It may look OK from across the street, but up close your trim has scratches, puckers, pits, and dents. Is there any way to restore these parts? If so, how do you know whom you can trust with these priceless parts?

To help us get to the bottom of this issue, we contacted George Iverson, owner of Iverson Automotive in Minnetonka, Minnesota. George started restoring trim for himself in 1970 and made it his full-time business in 1985. We've seen his work on a number of award-winning Mopars, and he agreed to share his experience with us.

Mopar Muscle - Is N.O.S. the best way to go if you can get them?

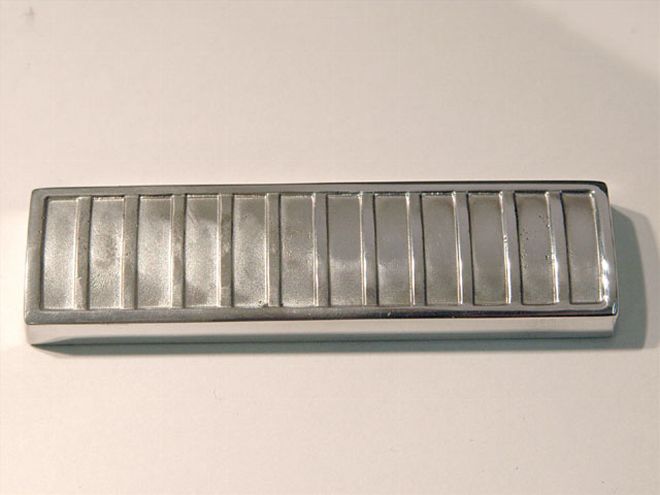

George Iverson - To many, N.O.S. is the Holy Grail of auto trim. people think because the part has never been on a car, and might still be in its original packaging, that it will look and fit perfectly . . . not necessarily so. First, there is the issue of shelfware. After a couple decades of being knocked around from place to place and carried to who knows how many swap meets, many, if not most, parts will need at least some repair. I've taken dozens of parts out of the original packaging that had dents, scratches, and pits (photo 1). Be especially cautious of online descriptions of chromed and aluminum parts that have a few minor scratches that can be "easily buffed out." If it is so easy, the seller would have already done it and described the part as show quality. the truth is, chromed and anodized aluminum parts cannot be buffed out.

All the major car makers used multiple suppliers for their trim parts. Not all the parts were perfectly identical. Parts from one supplier may be a little different from another. On the assembly line, parts were pulled from a bin, briefly inspected, and then attached to the car. If a part did not look good or didn't attach quickly and correctly, it was tossed into a rejection bin. The line workers didn't have time to mess around with a stubborn part. These parts were then repackaged and sold to dealers as replacement parts for collision repair. While not all N.O.S. parts were flawed or rejected by the factory, many were, and I would guess that most of the really good ones are used up already. My recommendation is simply this: whenever possible, use the part that came on your car. It will fit the best, and restoring it will probably cost less than buying another part-especially N.O.S.-and paying for it to be restored.

MM - You mean to say that even a small scratch can't be buffed out?

GI - Not with anodized aluminum and chrome-plated parts. A chrome-plated part is copper and then nickel-plated first, and the final chrome plating is actually very thin. If you try to buff out a scratch in a chrome-plated part, chances are you will polish right through the chrome and expose the nickel, which has somewhat of a yellow cast to it. The nickel will then oxidize quickly, and, even if you polish the nickel to match the chrome, within a few days it will change color again. To remove any scratch from a chromed part, it must be replated, not buffed out.

The same goes for aluminum parts. Nearly all aluminum trim parts are anodized from the factory. The only reason for this is to protect the part from oxidizing. Anodizing creates a hard, nonflexible finish. Any scratch on an anodized-aluminum piece is impossible to buff out. The entire piece must be completely stripped by soaking it in a solution of caustic soda, and then the part can be sanded and polished for a uniform finish.

Scratches aren't usually the toughest problem with aluminum parts. Look closely at an aluminum part, and you will likely see what looks like tiny specks in the anodizing. These specks are very small pits under the anodized surface, and there can be literally thousands of them (photo 2). The issue with anodizing is that it is very inflexible, but the aluminum it protects expands and contracts with the seasonal weather changes. This causes small cracks to occur on the surface. In fact, rear-panel trim exposed to hot exhaust gases usually suffers the most damage. Once the anodizing is cracked or broken, water, road salt, and other road chemicals will begin attacking the underlying aluminum. Given a little time, corrosion will start and eventually form a small pit. The only cure is to strip off the anodizing and then gently sand the part smooth again (photo 3). There is, of course, a limit to the amount of sanding that can be done, as these parts are typically not very thick, and you can easily sand right through the metal.

Once the part is restored, you can have it anodized again, leave it alone, and polish it from time to time to keep it from oxidizing, or clear coat it. If you intend to subject your car to the highest levels of judging, you will have to re-anodize. It's an expensive process, and, unfortunately, there are few companies that will treat your parts as the rare and valuable items that they are.

MM - Does it work the same way with pot metal? Can you just strip off the chrome and sand out the damage?

GI - Some restorers do it that way, and it might work OK if the corrosion is very minor, but I have found that it usually doesn't produce the best results. Fine detail can be lost, and, especially on flat surfaces, it will produce a wavy surface that is only emphasized by the plating (photo 4). Usually, by the time corrosion has broken through the chrome, the pit is too deep to sand out. It must be cleaned out and filled in.

MM - Is there a simple way to fill in the pits before the part is plated?

GI - Yes, the piece can be copper plated, and then sanded down repeatedly until the pits are filled in. This can produce good results if small changes in the part's size is not critical. Repeated plating, if it is not thoroughly sanded down each time, will cause the part to "grow" wherever it's not sanded; this can lead to pieces that don't fit properly. I paid $500 to have a taillight housing done this way. It looks great, but the lens won't fit it anymore. The only way to fix it now is to have it stripped back down to bare pot metal and start over (photo 5).

MM - looking at this taillight housing (photo 6), we see it's covered with some pretty deep pits. From what you've just said, we'd say this doesn't look like a good candidate for repeated copper plating. What else can be done?

GI - Drill out the pits (making sure to get out all of the corrosion), fill each one with silver solder, smooth out each spot, and then plate the part. I did half of this horn ring (photo 7) to show the before and after results of this method. Notice that the new chrome is not wavy.

MM - Let's talk about stainless trim. There's no coatings or corrosion to deal with, so can it be buffed out? What's the best way to do that?

GI - Actually, there are corrosion issues with some kinds of stainless parts, and there are some that don't respond well to polishing. Early automotive stainless was of very high quality, and it restores well, but as a result of the Korean conflict in the early '50s, quality stainless became in short supply. So the car makers were forced to make due with stainless that contained a high amount of iron. This inferior stainless can have rust on either side, and a magnet will have a mild attraction to it. Making restoration of these parts even harder, they were flash-chromed to prevent rust. this causes a problem similar to what we have with anodized aluminum. Anything that compromises the thin chrome veneer-a stone ding, a slight scratch, and so on-allows water, salt, or whatever to get at the stainless and cause rust and pits that can create a hole right through the piece. With some flash-chromed trim, the more you try to polish it the worse it looks. If you over-polish it, it can take on an orange-peel-like appearance because of the iron content. I'm sorry to have to say this, but not all stainless can be restored to like-new appearance, even if it is straight and has no dents.

MM - What is involved in restoring a piece of stainless trim?

GI - After I have cleaned the part on both sides of the damage, I need to determine if the damage is an "inny" or an "outy." This piece (photo 8) looks like an inny, but if you look closer, you'll see the dent has moved the ridge line over a bit, and that will have to be moved back into place from the outside first. Much like conventional sheetmetal work, it's important to use a dolly behind the area you are hammering on, but these areas are too tight to try to use anything made for sheetmetal. I've found that a piece of raw silicon pressed into the back of the damage works well (photo 9). It conforms perfectly to the shape of the part, and its rebound action maintains support under the work area. I use a light body hammer and work slow so I don't go too far.

Once the ridge is moved back (photo 10), I'll turn the piece over and, using a chisel, re-establish the crease so it matches the ridge on either side of it (photo 11). Now I can begin to work the dent out. My bench has a rolled kitchen counter top edge that makes a great dolly for tapping out these small dents. I use the chisel end of a body hammer and light rebound-type blows. Work from the outside of the dent towards the center. When I think I'm starting to get close, I'll turn the part over and lightly sand it with 220-grit sandpaper (photo 12). That will tell me what part of the dent still needs work. It's important not to go too far. Tap a little, and then sand a little. This is where the older stainless is nicer to work on. It's thicker, so you have more material to work with. When I'm almost there, I like to finish pushing out the damage with a pick similar to what the paintless dent repair people use. When you think you've got it, finish the repair with 400-grit sandpaper. Finally, use 500 grit to remove the sanding marks. If the part is just scratched but not dented, then you simply sand out the scratch. Now we are ready to buff.

MM - What kind of buffing wheels and compounds do you use?

GI - I use two kinds of wheels for stainless polishing: a sisal wheel made of coconut fiber to start with, and one made from spiral-sewn cotton as my finish wheel. However, I use a number of different compounds, so I have a buffer wheel dedicated to each (photo 13). The best compounds are the ones that come from Germany. A note of caution: buffing can generate a lot of heat, so be sure to use a good pair of welding gloves to protect your hands (photo 14).

MM - We understand you make your own coloring compound. Can you tell us about that?

GI - Coloring compound is the accepted final step when polishing stainless steel. This is what is supposed to give stainless its bright-chrome-like look. But no matter what compound I tried, I couldn't get the results I was looking for. It always seemed like there was a slight haze covering the piece, so I began to experiment with different compounds and combinations of ingredients that I would mix up in a food processor. After some years, I came up with a mixture that will make stainless trim look like mirrored glass. I'm not in the metal polish manufacturing business, but I have packaged four products for stainless, aluminum, chrome, and plastic (photo 16). They are for sale at shows and swap meets I attend so my customers can maintain their trim. It's a soap-based product that doesn't contain any petroleum distillates and can be applied with a machine or by hand.

MM - What is your recommendation for choosing someone to restore trim?

GI - Look for someone who values your rare and expensive parts as much as you do. I've sent numerous parts out to be restored as test pieces, and you'd be shocked at the differences in quality and attention to detail. For instance, there are a lot of places that will accept your pot-metal part for chroming, but it might not receive any more attention than the 100,000 doorknobs they are processing that week. Some of these parts can be quite delicate, so find someone who cares enough to handle them correctly.