One of the things we knew right away when we began this project was that the original Winters rearend that was in the ’01 USAC Silver Crown Championship winning car of Paul White would not work for what we are attempting to do. For starters, the rear was set up with a traditional torque tube, which would not mate up to the B&M 4L60E transmission we were going to use in the street application. Additionally, the car would not easily track straight as you drove down the road, thanks to the offset axles. Clearly our vintage Silver Crown car was going to need a custom-designed rear.

We wanted to keep with the theme of the car and stay true to its Silver Crown roots so only another quick-change would do. A call to Gerald Williams at Tiger Rear Ends produced the same reaction as we have heard from other people. He said, “You’re doing what?!” After a brief explanation as to the how and why, Williams easily caught on to what we were up to since he is a big car guy as well. (Ed. note, you ought to see the Mustang he is building.)

He had his team at Tiger whip up something special for us that, on the outside, pretty much looks exactly like a traditional quick-change rearend you would find in any Late Model, Sprint Car, or Modified. However, there are two major differences, one you can see, one you cannot. The easily visible option is the universal joint, which will allow us to run a traditional driveshaft. The not-so visible one has to do with the in/out box. Since Silver Crown cars are direct drive, meaning no transmissions, they are either in gear or out of gear, thanks to the in/out box. Our car has a t-handle on the end of a cable that actuates whether or not the gears were engaged. Simply put the cable runs down to the rearend, and pulling it will disengage the gears. Naturally, with our new setup the automatic transmission requires that the rearend gears are engaged all of the time. So the guys at Tiger set up our in/out box to be “in” all of the time.

Beyond those two changes, the installation of the new Tiger rearend into Project Silver Crown was very straightforward. We reused all of the original suspension components, including the birdcages. Follow along with us as we get to work.

The Torch gets to work pulling an old wheel off of the antiquated rearend.

The Torch gets to work pulling an old wheel off of the antiquated rearend.

In order to get the live axle rearend out of the car we’ll have to remove the birdcages, but we’ll be reusing them on the new rear. One thing we won’t be reusing is the old brake setup. We’ve got new ones coming that will be featured in a separate story.

In order to get the live axle rearend out of the car we’ll have to remove the birdcages, but we’ll be reusing them on the new rear. One thing we won’t be reusing is the old brake setup. We’ve got new ones coming that will be featured in a separate story.

Here’s a better shot of the old brake setup, as the Torch disconnects the lower trailing arm.

Here’s a better shot of the old brake setup, as the Torch disconnects the lower trailing arm.

The old rear dangles in the car ready to be removed. We’ll remove the tail tank first to make access easier.

The old rear dangles in the car ready to be removed. We’ll remove the tail tank first to make access easier.

This old rearend is extremely heavy and is definitely a two-person job to remove.

This old rearend is extremely heavy and is definitely a two-person job to remove.

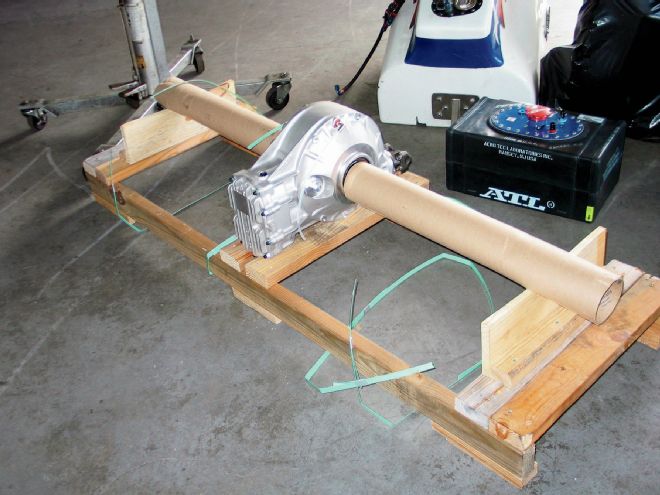

Even with the brake removed, the new Tiger rearend is substantially lighter than the one that was in the car. You’ll also note in this shot that our new rear has equal length axles, as opposed to the old rear. Remember this car is now going to be driven on the street, so to amp up the driveability factor we had Tiger design the rear without any offset to help the car track straight. Finally, the new rear has a U-joint while the old one has the traditional torque tube setup.

Even with the brake removed, the new Tiger rearend is substantially lighter than the one that was in the car. You’ll also note in this shot that our new rear has equal length axles, as opposed to the old rear. Remember this car is now going to be driven on the street, so to amp up the driveability factor we had Tiger design the rear without any offset to help the car track straight. Finally, the new rear has a U-joint while the old one has the traditional torque tube setup.

The new rear slides in without a problem.

The new rear slides in without a problem.

The original suspension components go back onto the new rear.

The original suspension components go back onto the new rear.

Since the axles are now the same length we had to swap the lower bars to center the rear and ensure that it lines up adequately with the transmission.

Since the axles are now the same length we had to swap the lower bars to center the rear and ensure that it lines up adequately with the transmission.

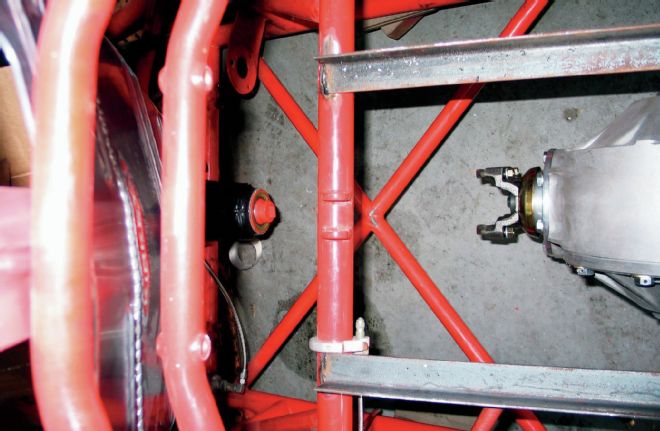

Boy did we get lucky. In this shot you can see that the simple lower bar swap we did centered the trans to the rear nearly perfectly. Had this not been the case we would have needed all new bars in the back.

Boy did we get lucky. In this shot you can see that the simple lower bar swap we did centered the trans to the rear nearly perfectly. Had this not been the case we would have needed all new bars in the back.

We catch Darrell, er uh “the Torch,” holding the rear up to check the alignment. We’ll install a top link later to help minimize wrap-up.

We catch Darrell, er uh “the Torch,” holding the rear up to check the alignment. We’ll install a top link later to help minimize wrap-up.

The conventional driveshaft slides into the transmission.

The conventional driveshaft slides into the transmission.

Because of the uniqueness of our application, the driveshaft had to be custom built and balanced. A local driveshaft shop turned it out in one day and it cost less than $300, both of which surprised us. We really thought it would cost more and take more time.

Because of the uniqueness of our application, the driveshaft had to be custom built and balanced. A local driveshaft shop turned it out in one day and it cost less than $300, both of which surprised us. We really thought it would cost more and take more time.

The finished drivetrain is in place and all bolted up. The only thing left to do here is to choose gears and that top link.

The finished drivetrain is in place and all bolted up. The only thing left to do here is to choose gears and that top link.

Several years ago in an effort to continually improve their product, the engineers at Tiger Rear Ends began collaborating with RF85. Manufactured by a Tennessee company of the same name, RF85 is actually a metal treatment whose name is derived from a coefficient of friction test performed by Oak Ridge National Laboratory. That test found the reduction of friction on a steel surface was 85 percent, thus RF (Reduce Friction) 85. Unlike a coating, the treatment becomes part of the metal and wears with the metal, not off of it.

Tiger performed their own set of testing over the course of an entire racing season. They began by having the RF85 processed into all the steel internal parts of the rear, including bearings and races, shafts, ring-and-pinion, and all the steel locker differential parts. At this point they assembled the rear and were off to the chassis dyno. The first run was made with a new Tiger rear with two races on it to get a baseline. Swapping over to the RF85 Tiger, they filled it with 41/2 quarts of oil and made a pull with no break in. The RF85 rear was comparable with the baseline rear. On the second pull, they lowered the oil level by 1 quart, for a total of 31/2 quarts. This pull showed an increase in power and the heat level was lower. The temperature was 161.2 degrees on the first pull compared with 156.7 on the second pull. On the third pull the oil level was again dropped by a 1/2 quart to bring it to 3 quarts, yielding lower temps and more power again. The test season ended with running a mere 11/2 quarts of oil in the rear that netted gains of 9 hp and 10 lb-ft of torque, plus the heat level was actually lowered to 152 degrees.

For the track testing portion, Tiger ran the rear ragged over the course of an entire season of pavement Late Model racing. After each race they would progressively lower the amount of oil run in the rear until the last three races of the season were run with just 1 quart of oil. After 18 races the rearend looked like the day it was built and the temperatures never exceeded 195 degrees F during those races. The RF85 treatment allowed the rearend not to fight the windage, which gave the car a quicker response and at the same time reduced wear on the parts.

Tiger Rear Ends is the exclusive distributor of RF85 so if you’d like to get this same type of performance go get yourself a Tiger.