It may be one hot mess, but at least it's a functional mess. To say that Chrysler engineers came up with a unique kick-down mechanism for the A727 transmission is a bit of an understatement. In lieu of a kick-down cable, the TorqueFlite uses a series of rods, bellcranks, levers, and brackets to initiate a downshift when the driver's right foot gets heavy. This complex arrangement works remarkably well as long as a car is stock. Unfortunately, that harmonious interaction of moving parts goes entirely out the window once engine mods enter the mix. Since few hot rodders leave their cars completely stock, improper kick-down performance has plagued legions of the Mopar faithful for decades.

We tackled this dilemma head-on in our '68 Valiant project car, which packs a TCI A727 Street Fighter transmission matched to an Indy Cylinder Head 500ci wedge motor making 657 hp. To get it all sorted out, we sought the expertise of Mopar specialist Jason Muckala at Motech Performance. Fortunately, the fix is as easy as installing an inexpensive Lokar kick-down cable assembly, which we found at a great price at Speedway Motors. While we were at it, we also got Lokar's High-Tech Mopar throttle cable assembly and throttle bracket kit with throttle return springs.

The inherent problem with rigidly mounted kick-down linkage components is that they offer no flexibility once performance mods are added to the equation. More specifically, any changes to the induction package—or even the short-block—that alter the positioning of the carb throttle lever in relation to the kick-down linkage can seriously mess up transmission performance.

Since few hot rodders leave their cars completely stock, improper kick-down performance has plagued legions of the Mopar faithful...

Says Jason: "In the factory kick-down system, there's a rod connecting the carb to a bellcrank on the back of the cylinder heads, another rod connecting the bellcrank on the heads to a bellcrank on the bellhousing, and finally a rod connecting the bellcrank on the bellhousing to the kick-down lever on the transmission. It works incredibly well, but only if you have all the right parts," Jason explains. "Simply replacing a two-barrel carb for a four-barrel carb completely messes up how the kick-down system works. The throttle cable is longer for a four-barrel carb, so when you try to use the linkage off a two-barrel carb it's too short. When upgrading from a small-block to a big-block, or a low-deck to a tall-deck block, or a wedge to a Hemi, each specific combo requires a very specific combination of kick-down linkage components to make it all work. It gets even more complicated if you use non-stock parts like a high-rise intake manifold or a dual-quad carburetor."

With so many factors involved in making the kick-down system work properly, it's hardly surprising that hot rodders have come up with some interesting solutions over the years. "I've never had a Mopar come into the shop where the kick-down linkage was adjusted properly, and the consequences range from poor shift quality to completely destroying the transmission. People do all kinds of goofy stuff like using Vise-Grips, baling wiring, and welding on bolts," Jason reports.

Despite what may seem like a whole lot of doom and gloom, one afternoon in the garage and a couple hundred bucks is all it takes to solve kick-down system issues for good. For stock restoration applications where every last part must be stock, A&A Transmissions has done the hard work for you by packaging complete kick-down linkage assemblies for every conceivable factory engine and induction combination into over a dozen turnkey kits. That route is entirely appropriate for Mopar fans who want to retain the look and performance of the factory setup.

Nevertheless, for the typical street machine that is modified in some form or another, Jason feels that Lokar offers the ideal solution to simplifying the factory kick-down system. "By replacing all the factory rods and bellcranks with an adjustable Lokar kick-down cable, it eliminates the possibility of mismatched parts. This also opens the door to running any engine, carb, and trans combination you want. Having a small cable instead of bulky rods also makes it easier to route around the headers," he says. The solution is so simple it's genius.

...one afternoon in the garage and a couple hundred bucks is all it takes to solve kick-down system issues for good.

A single Lokar kick-down cable takes the place of three rods, two bellcranks, and multiple brackets. Since it's adjustable, it can easily compensate for any future changes to the cylinder heads, intake manifold, or carburetor.

Anyone who has wrenched on Mopars probably has a box full of A727 kick-down components already. Installing an adjustable cable saves the headaches involved with trying to figure out the ideal combination of factory linkage components to make the kick-down system work properly. These are just a few various bellcranks, rods, and kickdown levers that the factory put out.

From the factory, Chrysler used many different length kick-down levers on the A727 TorqueFlite. Ideally, the lever length should be optimized so that when the throttle cable moves 1 inch, the kick-down lever moves 1 inch. Failure to achieve a proper 1:1 ratio will result in poor shift quality in a variety of forms including early downshifts, soft shifts, too hard of a shift, late downshifts, and more. Getting the length right requires swapping out levers, or sometimes even lengthening or shortening an existing lever. Note the shift lever mounted concentrically, and just below the kickdown lever.

To give you an idea of what you're up against in terms of how many factory kick-down linkage types there are, here are just a few possibilities. This display of OE kick-down linkages taken at the Mopar Nats belongs to A&A Transmissions—one of the few experts in the field. If you absolutely have to go with a stock kick-down linkage, A&A would be a good place to start. Just understand that anything that changes any part of the geometry will degrade the kickdown function. This includes a carb upgrade, a manifold swap, an engine swap, an engine set back, a change in the firewall, or even adding a carb spacer.

To get our powertrain combo set up right, Speedway Motors set us up with the Lokar kick-down cable kit (PN KD-2727HT) for $79.99. It features an extruded liner to extend cable life, and aluminum ferrules and fittings to eliminate frayed cable ends. There's also a ton of adjustability to get the downshift tuned perfectly.

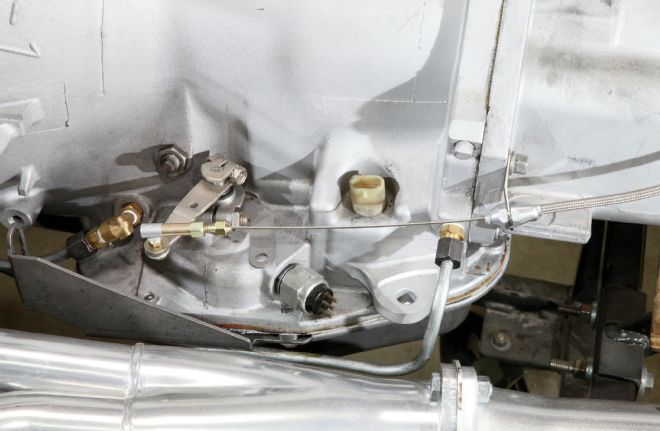

The ball fitting on the new Lokar cable allows for plenty of flexibility in cable movement. Before securing it to the kick-down lever, it may be necessary to grind down the extra threads on the fitting to prevent interference between it and the shift lever just below it. Note that the kick-down lever does not come with the Lokar kit—you will need to get that from your trans supplier. A&A Transmissions is another good source.

The Lokar kick-down bracket attaches to the tailshaft housing using the outermost factory bolt on the driver side. In essence, the Lokar cable pulls back on the kick-down lever whereas the stock linkage pushes on the lever from the front. This makes routing the cable a lot easier, and enables many more options with aftermarket headers and suspensions.

Unlike the factory kick-down linkage, the Lokar cable runs rearward toward the driveshaft before snaking forward toward the carburetor. This routing keeps the cable away from the exhaust for improved clearance, as you can see in this mocked-up LA-series small-block/727 combo.

For the cleanest packaging possible on Project Valiant, we matched the Lokar kick-down cable (bottom) with the Lokar's throttle-bracket (PN SRK4000; $26.99) and throttle cable kit (PN 1000HT-24; $49.99). Both cables can be trimmed to length. The front of the kick-down cable attaches to the carb bracket by tightening down on a hex fitting, while a return spring provides the right amount of tension. With the kick-down lever on the transmission in the center of its travel, Jason pulled all the slack out of the cable, and tightened the cable stop up against the slide fitting.

While sorting out the kick-down cable, we installed a TCI Outlaw shifter at the same time. (We'll have that story to you soon.) Since the kickdown cable and shifter cable ride on concentric shafts, the shifter lever—which is included with the TCI kit—must be installed first (shown) before the kick-down lever is attached.

For restorations where every last nut and bolt must be stock, A&A Transmissions has taken the guesswork out of piecing together a factory-style kick-down system. The company offers turnkey kick-down kits for just about every Mopar engine and trans combo ever made by the factory.

How The Kick Down Lever Works

As the kick-down linkage/cable pushes the kick-down lever rearward, it increases line pressure inside the trans and initiates a downshift. "If you adjust the cable so the lever is at the front of its travel range at idle, the line pressure will not increase properly as the throttle increases," Jason Muckala of Motech Performance explains. "This makes the trans shift too early, and it can cause the clutches to slip and destroy the transmission. I've seen people install springs to hold the lever forward, but it's not supposed to stay in that position at idle." This photo shows the lever full forward; in this portion of the lever's arc you can feel no pushback from the lever, an indication that no increase in line pressure is occurring.

Somewhere in this range of the lever's arc, you can feel a slight resistance from the lever's internal spring. This is where the line pressure begins to rise, ultimately causing a downshift. Properly dialing in the lever's range of motion is critical to shift performance and transmission longevity. Says Jason: "For the first half of its travel range, there is very little resistance and the lever does nothing. At the halfway point, you can feel where it starts to hit the valve inside the trans, and that's the position the lever must be in at idle."

At WOT, the kick-down lever should be positioned at the end of its range of travel. This ensures accurate shift points and a proper increase in line pressure. Factory kick-down linkage setups can create scenarios where the kick-down lever will not move all the way back at WOT, or scenarios where the lever moves all the way back and hits a hard stop before WOT. Now you can begin to understand why it's important for the bellcrank on the throttle shaft to move in perfect sync with the kickdown lever on the trans in a 1:1 ratio.