In the Sept. ’12 issue of HOT ROD Deluxe, we took a graduate class from Garage Motorsports in beefing Muncie four-speeds for street duty (“Crash Course”). That feature closed with a tease of home-brewed hybrid overdrive trannies that triggered a lot of reader interest. So we’ve returned to Scott Petersen’s tin classroom in Vancouver, Washington, for overdrive lessons. We learned that driving the best of both worlds (acceleration and cruise speed) down the highway is relatively simple and extremely rewarding, if you have the hardware.

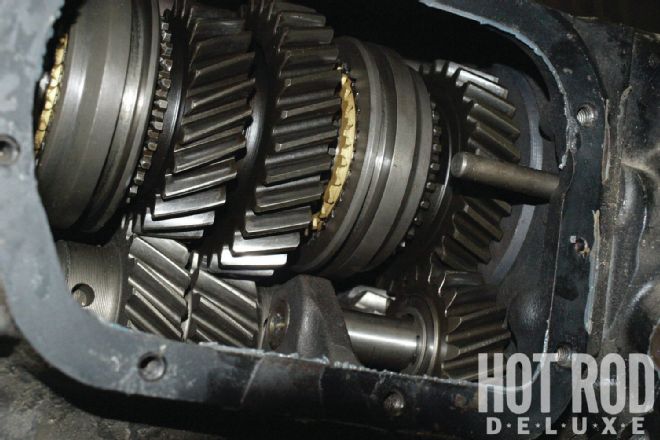

Like any relationship, it takes two to make one. In this case, that means a Saginaw full synchro three-speed overdrive transmission (identified by its seven-bolt side cover) and a Saginaw four-speed (also seven-bolt), both prevalent in numerous mid-’60s to mid-’70s GM cars and trucks. The challenge is finding a seven-bolt Saginaw three-speed overdrive transmission these days. Once as common as the mud they sank into at wrecking yards across the nation, they are now considered rarities. But we know many of you pack rats have at least one sitting around, waiting for a rainy day. Let it rain. The result of this mash-up is a four-speed with overdrive that will deliver snappy launches and effortless freeway flying, while keeping your ride period correct, right down to the drain plug.

Inherently modular, the Saginaws allow for some creative mix-and-match customizing. This particular exercise involves nothing more than installing a three-speed mainshaft into a four-speed case. The most exotic skill required is fabrication of a reverse-gear shift-lever cam arm. You’ll also have to drill a hole and cut a piece of 3⁄8-inch steel rod. A Saginaw overhaul manual (sourced online or at the library) will answer any assembly questions you may have.

Sleuthing through the Garage Motorsports compound turned up these two prospective seven-bolt Saginaw three-speeds with the BorgWarner R-10 overdrive (tailshaft housing/overdrive casting number R10Q-1, which fit the seven-bolt Saginaws only). Both main cases were cracked open on the bench to see if the internals were intact. They were. Our goal was to harvest the mainshafts and any associated incidentals. Petersen noted both trannies originated from passenger cars (identified by their front bearing retainer outside diameters: 45⁄8-inch on passenger cars, versus 51⁄8-inch for trucks). That canister hanging off the driver’s side is the coveted R-10 overdrive unit solenoid, once employed as cheap door poppers on myriad customs, and now rare as hen’s teeth and snake hips, combined.

Petersen dropped this disclaimer before class began: “There’s more than one way to do anything. This is how I do it. It works. But I advise keeping horsepower levels down to ‘not much,’ as these trannies were designed to back mostly six-cylinders and some base model V8s.”

There are four common First gear ratios to choose from, identified by grooves on the input shaft: no groove, 2.85:1; one groove, 2.54:1, two grooves, 3.11:1; and three grooves, 3.50:1. The 2.85 and 2.54 are the most popular, as they accommodate the needs of most drivers. The 3-series ratios were intended for four-cylinder cars in need of assistance off the line. We found a 2.85 gear on the shelf and grabbed it. Once that decision was made, we got to work.

While side cover removal exposed no drama, further disassembly revealed damage to the pocket bearing inner race in one trans and chunks of bearing caging in the other. Petersen deemed it, “Typical. About 20 percent of ’em are this way.” Removal and inspection of the tailshaft housings, override cams, planetary gears, output shafts, center bearing supports, speed gears, and shift hubs proved these components to be roadworthy. We salvaged the roller bearings (which are no longer available) from the freewheeling direct-drive hubs and removed the snap rings and oilers from the center bearing supports. As for that mainshaft wear, Petersen advises, “Yeah, it’s ugly, but don’t throw it away. Mainshafts are all rare these days.” Luckily, Garage Motorsports can re-tip any shaft, and did so to this one in minutes.

Our overdrive conversion is Petersen’s standard procedure; nothing fancy here. The parts were swapped during a basic rebuild, using stock replacement parts. You can do it in an afternoon on the kitchen table.

The black three-speed had a big surprise waiting inside for us. As Petersen said, “Is this N.O.S. stuff in here? It’s the nicest one I’ve ever seen.” There were no witness marks to be found, and the gears were cherry. Score!

The black three-speed had a big surprise waiting inside for us. As Petersen said, “Is this N.O.S. stuff in here? It’s the nicest one I’ve ever seen.” There were no witness marks to be found, and the gears were cherry. Score!

We grabbed a Saginaw four-speed case (cast to accommodate a reverse idler gear unique to the four-speeds) to install our parts into. The case checked out as sound, so we power-washed and bead-blasted it, then treated it to a sexy rattle-can paint job. This will be the new container for the excellent hardware found inside the three-speed cases.

Left to right: The center bearing support, sun gear, planetary gear, freewheeling direct drive main gear, and ring gear on the three-speed output shaft, cleaned and laid out for assembly. These parts are the keys to creating our overdrive. Old-time assembly tip: Use assembly grease and a rubber band to contain the freewheeling direct drive roller bearings (the smaller drum with rectangular openings).

The sun gear, planetary, and shift lever, mounted on the mainshaft (our freewheeler will crown this stack of goodies).

The sun gear, planetary, and shift lever, mounted on the mainshaft (our freewheeler will crown this stack of goodies).

The ring gear on the output shaft, topped with the bearing, ready to load onto transmission main shaft -- once we install roller bearings over the freewheeling direct drive, using a rubber band to hold the bearings in place. Install the ring gear over the override and planetary gear, then install tailshaft housing. Internal assembly is now complete.

Finished Product

The finished product gives you four forward speeds, plus electrically controlled 30 percent overdrive. This is a relatively simple conversion, and it’s all done with vintage parts that look at home on your period hot rod. Petersen’s final words on running this combo: “Do not put synthetic or EP-rated oil in these transmissions. Use a GL1-rated mineral-oil-based gear lube. The overdrive takes 4 pints. The main case and tailshaft housing have separate fills and drains. I stock parts for these but will refer you elsewhere if I’m out of something.”