There are several different choices available when it comes time to decide what rear end your car needs. The main thought to keep in mind is the intended purpose of the car that the rear is going into. If your only plan is to drive your Slant-Six powered Dart around town and to cruise nights, then a Dana 60 would not be the kind of rear end that you need. Mopar cars came from the factory with anything from the small 7-1/4 rear, the slightly tougher 8-1/4 rear, the really tough 8-3/4 rear, and the legendary Dana 60.

Now, if you’re planning to build a high-horsepower car that will really test the rear end’s survivability, then nothing less than an 8-3/4 rear should be used. The 8-3/4 came in a lot of different configurations, and if you can’t find the perfect bolt-in unit, modifications can be made to install just about any rear end into any car. But what if you’re not sure how to handle the modifications? What if you simply want a rear end that can be bolted in? Finding a bolt-in rear end is as easy as calling a used parts dealer, hitting the local swap meet, or having a buddy that has one he’s willing to sell. Even if you find one, at a minimum, it should at least be torn down and checked out. Again, if this is something you’re not comfortable with, there is another alternative.

It may not look like a stock rear, but there’s nothing stock about our Valiant. We chose to use the fabricated housing and True Trac differential in our 489 case with 33-spline axles.

It may not look like a stock rear, but there’s nothing stock about our Valiant. We chose to use the fabricated housing and True Trac differential in our 489 case with 33-spline axles.

Complete, bolt-in rear ends are available in many styles and levels of unbreakability. For instance, Moser Engineering can build you a complete, all-new rear for your car in either an 8-3/4 of Dana 60. Now, some may argue that buying a completely new rear end costs too much. But, if we look at it this way, a swap meet A-Body rear end can go for around $700-$800. If you’re lucky, you can simply bolt it in your A-Body and go. But what if you want to change the gears? What if you find out that an axle is bent--or worse yet, the axle tube! I know I am talking about worse-case scenarios, but it is a possibility. If you have to completely rebuild the swap meet rear, is it really any less expensive than an all-new unit? OK, if you have a numbers-matching, completely restored and date-coded Mopar, maybe you need to stick with factory parts, but the cruiser and drag race guys have nothing holding them back.

We contemplated the above scenario at length after we built the new engine for our old-school Valiant. The rear end that was in the car had seen its share of smoky burnouts, 5,000-rpm clutch drops, and more sideways action than any rear end should be exposed to. Now, since we realized that a new rear end was in order, we only needed to decide what we really needed. With the intended purpose of the car being able to test the survivability of an 8-3/4, we knew that nothing less than that would work. But, was a Dana 60 really warranted?

We decided that a 4.10 gear would be just about right with our 27-inch-tall tire and four-speed. We then pressed the inner pinion bearing in place so we could begin our task of measuring for clearances. Until you have the proper pinion depth achieved, you will not place the compression bushing on the pinion gear. This gets done during final assembly. If you use the 742 case, there is no compression spacer.

We decided that a 4.10 gear would be just about right with our 27-inch-tall tire and four-speed. We then pressed the inner pinion bearing in place so we could begin our task of measuring for clearances. Until you have the proper pinion depth achieved, you will not place the compression bushing on the pinion gear. This gets done during final assembly. If you use the 742 case, there is no compression spacer.

The Dana 60 is bulletproof--period. But we felt that it might be slightly overkill for a small-block powered A-Body, so an 8-3/4 would be what we need. Now, we also found out that when it comes to an 8-3/4 rear, we still had two choices--are you confused yet? Moser Engineering’s two new 8-3/4 housings come in either a stamped (OE look), or fabricated (Boxed look). All Moser 8-3/4 stamped Mopar housings are made with new heavy-duty housing cores, seamless steel tubing new brackets, new housing ends. The fabricated housings are made from 18-inch thick laser cut mild steel, which is fabricated from one triangulated piece of metal. This is combined with a 3/8-inch-thick face plate, and internal gussets and bulk heads, which are standard, seamless steel tubing, new brackets, and new housing ends. It also includes a custom machined fill cap, drain plug, and vent along with the stud kit for mounting the centersection. Since the stamped and the fabricated rear housings are all but the same cost, we thought the fabricated housing looked cool enough, so that’s what we went with.

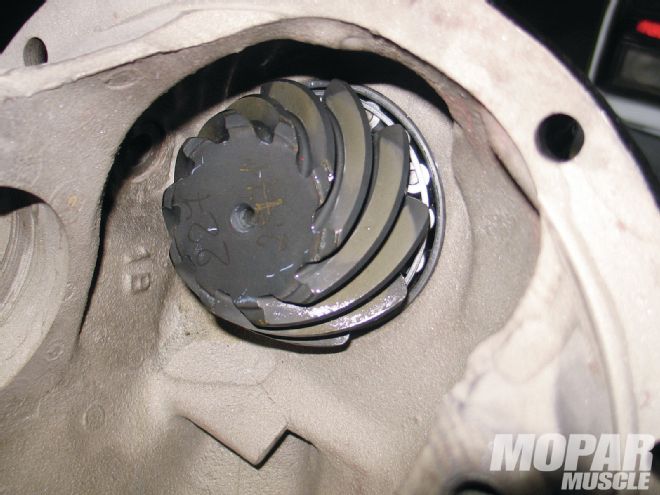

Now we had to figure out what to do for the centersection. Using a 489 center housing, we had the choice of using a spool--not street friendly, a Sure Grip, or an entirely new mousetrap so to speak, the Eaton/Detroit True Trac differential. The True Trac differential uses a worm-gear design that will bias the engine’s torque to both wheels evenly. According to Eaton, there are no parts or clutches to wear out and no need for adding the Sure Grip additive.

Although it is hard to see in this image, the manufacturer has inscribed pinion depth numbers on the face of the pinion gear. This is the measurement needed as taken from the center of the side-bearing opening, and the face of the pinion.

Although it is hard to see in this image, the manufacturer has inscribed pinion depth numbers on the face of the pinion gear. This is the measurement needed as taken from the center of the side-bearing opening, and the face of the pinion.

If you decide to take the leap and get a complete housing from Moser, what you will get is a complete housing that is ready for you to put your brakes on, and bolt in the car. What we did is to order all of the parts to show you how it goes together and what’s inside. Before you call and order your rear end though, take the time to call the folks at Moser and discuss your needs. They have been doing this for a long time and can direct you in the right direction to get just what you need.