Don't let a rearend issue sideline you this year. Most problems could easily be avoided just by having a properly cooled rearend.

Don't let a rearend issue sideline you this year. Most problems could easily be avoided just by having a properly cooled rearend.

It's late July and teams are looking for the best ways to keep their engines as cool as possible. But with all the attention being paid to the motor, there is something at the other end of the car that can be easily forgotten, the rearend. Most of us will just put the gear in, fill up the fluid, and not think anything else about it. Later that year when we start going through the teardown process, we notice that the rear gears are pretty well burned up and need to be replaced. Even if you're only running 50 laps at your local short track every Friday night you might want to think about taking some steps to ensure that you don't overheat your rearend. Ultimately, it will save you money.

The rearend of your race car experiences a significant amount of stress and heat. Think about it, the rearend is responsible for accelerating a 2,200 to 3,400 pound race car forward by transfering the energy produced by the motor/trans to the rear wheels. Without the proper maintenance and, in certain cases, a system for keeping it cool, you'll considerably shorten your rearend's lifespan. I've seen many teams just accept the black and burnt smell when they drain the rearend oil as the norm. But trust me, this is a problem.

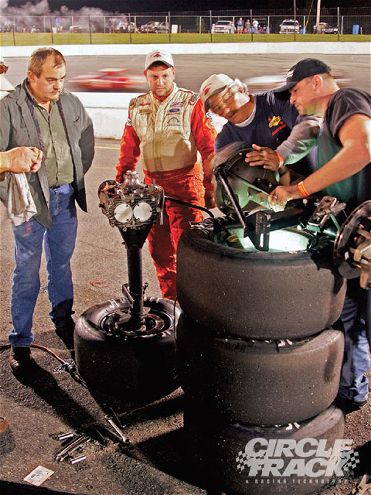

This is the situation you don't want to be in. The race is going on and you're sidelined having some work done to your rearend. There are steps you can take to avoid these problems.

This is the situation you don't want to be in. The race is going on and you're sidelined having some work done to your rearend. There are steps you can take to avoid these problems.

The problem will not only lead to a rear-gear failure, but it will also increase the wear on the parts inside the rearend. For instance, the ratchet springs in your locker rearend control how the power is distributed to the rear wheels. When these springs "go out" or wear beyond their usable life, it causes a car to be a handful to drive. Here's why-prolonged use and/or excessive heat will cause a loss of spring rate (the spring actually loses height). In that case, one of two things will happen under acceleration, either both sides will lockup together, which is exactly what we want, or one side will not lockup at all, which is a problem.

However, there is good news. There are some simple and easy steps to take to avoid being sidelined by an overheated rearend.

Inspect And Change The Oil

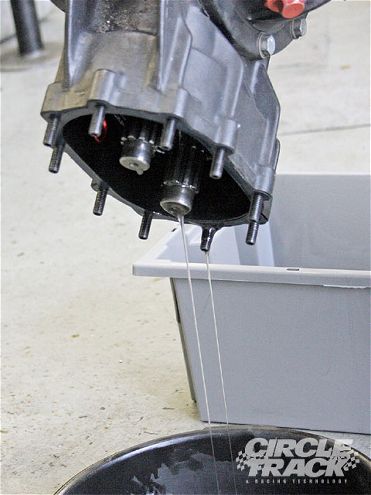

Regardless of whether or not you're going to change the gears, you should inspect and change the oil in your rearend each week. It's the simplest and most effective of steps, but with that being said it's the most commonly overlooked step as well. Other than completely taking apart the rearend and inspecting it, the rearend oil is the only thing we can inspect to see what is happening inside. If the oil comes out black and smelling awful, then you know that you have overheated the rearend. Inspect not only the color, but also pay careful attention to any debris build up. Specifically, how much debris is there? You'll more than likely see a little metal in the form of minute shavings. But you shouldn't see any pieces of metal larger than a pinhead. This would signal a problem in the rear. I always drain my oil into a clear container and then let it sit for an hour or before really inspecting it. The time sitting allows any foreign material to settle to the bottom of the container, easily spotted thanks to the clear glass jar.

Emptying your rearend fluid every week and inspecting it will go along way in keeping clean and fresh fluid in the rearend.

Emptying your rearend fluid every week and inspecting it will go along way in keeping clean and fresh fluid in the rearend.

Changing the oil weekly may seem like overkill, especially considering that rearend oil isn't the cheapest stuff in the world, but changing the oil weekly helps in reducing operating temperatures espcially in longer races.

Before I move on to the next item, here's a quick word about qualifying oils. Some manufactures have a qualifying oil specifically designed for rearends. Often found in the upper levels of racing, this lubricant is extremely thin and will help create a little bit of horsepower for qualifying. However, if you can't change the oil immediately after qualifying don't even try to use it for the race. These lubricants are designed for one- to two-lap runs and won't last for even a 20-lap feature.

Install A Rearend Cooler Don't think just because you run a quick-change rearend that you don't need a rearend pump to keep the oil circulating through a cooling reservoir. Tiger Rear Ends has a direct drive external pump that works off the gear shaft. The relatively small pump will circulate oil throughout the entire rearend. Tiger will even install it into the back of the gear cover for you.

Want to do it yourself? Since it requires machining, this is one of those instances where it's better left to the professionals.

Now the rearend cooler will act as a reservoir if it's mounted correctly which will constitute a relatively small increase in oil supply. If you choose to run a rearend cooler, the process of filling the rear with oil is relatively straightforward.

What I usually do is take the rearend oil and pour it into a clear container and let it sit for a while so that we can inspect it.

What I usually do is take the rearend oil and pour it into a clear container and let it sit for a while so that we can inspect it.

First fill the rearend to the manufacturer's recommended level (usually marked), then spin the rearend to pump oil into the cooler to fill it. This can be done by jacking the rear of the car up, starting it, and putting it in gear. Finally, replace the oil in the rear that was pumped into the cooler.

An external pump will cost you somewhere between $250-300-that's pretty inexpensive when you consider replacing the entire $1,800 rearend.

The other type of pump is an internal pump, designed mostly for you guys and gals running a 9-inch rearend. External pumps can be a little bit of a headache when you're installing a new rear gear. However, the internal pump has everything contained inside. The downside is that every rear gear has to have an internal pump.

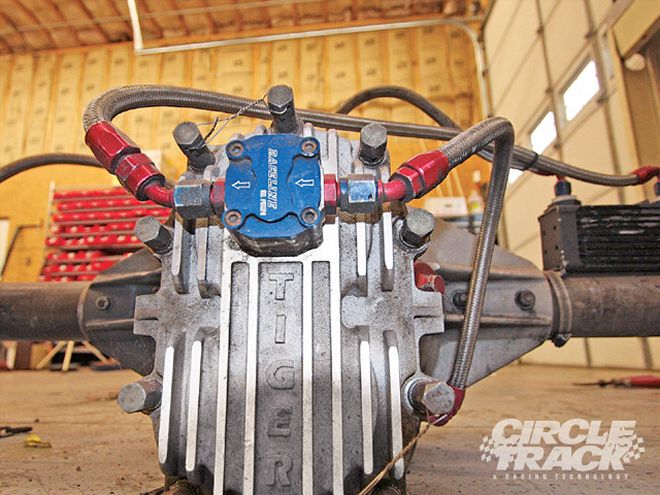

This is one form of an external oil pump. This setup is available through Tiger Rear Ends. It attaches to the back of the gear cover and pumps oil through a cooling reservoir and then back into the rearend.

This is one form of an external oil pump. This setup is available through Tiger Rear Ends. It attaches to the back of the gear cover and pumps oil through a cooling reservoir and then back into the rearend.

For our project USAR Pro Cup car we run a 9-inch rearend and fall into the category of running an internal pump. C&R Racing supplies us with the gears at each race through its rental program which works out great for low-budget teams like us who can't go and test before each race to determine the right gear. Plus, each of these rental gears comes with an internal pump, making changing the gears extremely easy. All we have to do is undo the hose and pull the rear gear out and put the new one in and reattach the hose.

To Treat Or Not To Treat

Metal treatments are another excellent way to reduce the wear and tear on your rearend-and there are a number of them out there. The Feb. '09 issue of Circle Track has a story that showed how some teams used only one quart of oil in their rearends thanks to Tiger's new RF-85 treated Quick Change Rearend. We found that the RF-85 Metal Treatment actually lowered the operating temperature of the rearend. The team in the story ran as little as one quart of oil and it gained a small horsepower advantage. Less rearend lubricant translates into more horsepower if the gears and internal components can stand up to the heat and stress. Tiger's RF-85 rear proved that to be the case and even saved the team some money on buying rearend lubricant.

This is the other version of an external oil pump. It attaches to the rearend yoke and spins. This setup can be a pain for the 9-inch rearends, but might be a decent setup for a quick-change rearend.

This is the other version of an external oil pump. It attaches to the rearend yoke and spins. This setup can be a pain for the 9-inch rearends, but might be a decent setup for a quick-change rearend.

Metal treatments like RF-85 are perfect for a Dirt Late Model or an Asphalt Late Model team running a quick-change rearend. You can gain the benefits of a metal treatment by just treating the main gear. Conversely, the design of a 9-inch would require you to have every gear treated in order to realize the benefits which would in turn increase the cost.

Install A Temperature Gauge

I once leaned in to a Super Late Model to talk to a friend of mine and I noticed that he had two temperature gauges on his dash. After the practice session I asked him about it and sure enough one of them was the temperature of the rearend. I thought this was sheer genius. I'd never even thought about wiring a gauge to the rearend. Most of us take for granted that the rearend is running at the correct temperature. But if it gets too hot, disaster could be lurking around the next turn. A good temperature gauge will allow you to spot trouble well before it becomes expensive.

Installing one is pretty easy as well. The rear oil temperature sending unit should be installed inline with the return line from the oil cooler to the rearend so it can monitor the "cooled" oil temperature. This is similiar to oil temperature gauges installed in the motors. Just be careful to keep its wires free of the driveshaft or other obstructions that could cause damage.

Conclusion These steps may seem elementary, but it's amazing how we get concerned with the setup while forgeting even basic maintenance on the rearend. This season, take a closer look at the rearend, it may just help you get to Victory Lane.