We started with three different rearends, all with the same gear ratio. Our test would determine which one puts the most power to the ground.

We started with three different rearends, all with the same gear ratio. Our test would determine which one puts the most power to the ground.

We've all heard that the Ford 9-inch is the strongest rearend you can buy. According to the Ford guys at least, it's also the best overall decision for strength and durability. If pressed, they'll also accept that the 9-inch might eat a little more horsepower than the other-style rearends. Numbers are also tossed about like resolutions on New Year's Eve, but no one seems to know exactly. We've also heard that the Dana 60 is a killer piece but that it's monster heavy and overkill for anything short of a blown Hemi on steroids. What you also notice is that opinions on strength and efficiency tend to follow party lines. In other words, the Ford guys will vote for the 9-inch, the Chrysler guys will wave the Dana 60 flag, while the GM guys all line up behind the 12-bolt. No surprises there.

We decided to cut through the brand-loyalty blindfold to take a clinical look at the 12-bolt, the Ford 9-inch, and the Dana 60 rear axles. We obtained a 3.50:1-gear version of each of these three rear axle assemblies that would bolt into an early Chevelle to see which one eats the least power and also investigate how strong each assembly is, relative to the others. We enlisted the help of Currie Enterprises, Moser Engineering, and Strange Engineering to supply both parts and expertise with this evaluation. Then we chassis dyno-tested all three at Westech on a SuperFlow SF-790 using our small-block Chevelle to see which one could put the most power to the ground. We chose a Chevelle mainly because it was accessible and because the 383ci small-block made decent power at the crank. The results were certainly worth the effort.

GM 12-Bolt

We started with a stock, early Chevelle 12-bolt housing that had been modified by Sutton Engineering with Moser large Ford bearing housing ends that allow the use of either stock drum brakes or a bolt-on disc-brake package. Because the original 12-bolt housings are now more than four decades old and hoarded by collectors, Moser offers brand-new bolt-in housings along with axles for a reasonable price. The larger Ford bearings are much stronger and use a four-bolt axle retainer plate, like a Ford 9-inch. This eliminates the stock C-clips and uses an aftermarket Moser 30-spline axle. We could have opted for a 33-spline axle, but we felt we didn't need that kind of strength for this test.

We also spec'd a set of Moser 3.55:1 street gears, a Detroit TrueTrac limited slip, and a 1310-series U-joint pinion yoke. To add a little more strength, we also included a Moser aluminum rear cover that uses Allen preload bolts to support the main caps under load. Tim Moore installed the ring-and-pinion for us. While we chose Moser as our source for 12-bolt parts, Currie and Strange also offer complete 12-bolt rearend assemblies as well as individual components.

DESCRIPTION PN SOURCE PRICE Moser 12-bolt housing, A-body Call Moser Moser Engineering $919.00 Moser 12-bolt housing ends 7900 Moser Engineering {{{80}}}.00 Moser 12-bolt retainer plates 9900 Moser Engineering 15.00 Moser 12-bolt 30-spline axles Call Moser Moser Engineering 315.00 pair Moser 12-bolt 3.55 gears 12B355R Moser Engineering 210.00 Moser 12-bolt pinion yoke, 1310 PY110 Moser Engineering {{{90}}}.00 Detroit TrueTrac, 30-spline 5TT555 Moser Engineering 465.00 Moser aluminum cover 7110 Moser Engineering 160.00 Moser setup kit R12B Moser Engineering {{{100}}}.00 The Ford was the first rearend assembly that we tested. By the third rearend install, Westech's Ernie Mana and the author swapped housings in less than 30 minutes.

The Ford was the first rearend assembly that we tested. By the third rearend install, Westech's Ernie Mana and the author swapped housings in less than 30 minutes.

Ford 9-Inch

The most popular performance rearend housing for musclecars has to be the Ford 9-inch. Before companies like Moser began reproducing the 12-bolt housings, the 9-inch was the choice for a bulletproof rear axle assembly. Currie offers several different ways to slip a 9-inch into a Chevelle, from brackets that you weld to your own housing to a complete, assembled housing where all you have to do is add gear oil and bolt it in place. We went with a Currie housing with 31-spline performance axles and a 9+ Sportsman centersection. This nodular unit is stronger than the factory cast-iron centers, so it can take more abuse without cracking. To this we added a 3.50:1 gearset along with a Currie-built 31-spline Torque Sensitive Differential (TSD) clutch-type limited slip. Along with an iron pinion support and a complete bearing set, we finished it off with a Ford 11-inch drum-brake assembly. This is the system we installed in our Chevelle, but Currie offers dozens of other options for the 9-inch. As with the other rearends, Moser and Strange also offer parts and assembled 9-inch rearends for most popular muscle cars.

Strange S60

Strange calls its version of the Dana 60 the S60 because these are not rebuilt housings but all-new nodular iron castings designed specifically for each application. Strange offers this S60 for a variety of body styles, including early Camaros, Chevelles, and G-body cars as well as all kinds of Mopar applications. The Dana/S60's legendary strength comes from its 9.750-inch-diameter ring gear and massive 35-spline axleshafts. This does add weight (see Rearend Weigh-In sidebar), but not nearly the heft you might expect. The 3-inch-diameter tubes are completely welded into the centersection, and the housing ends allow use of the stock Chevelle rear drum brakes after enlarging the center hole to clear the 3.150-inch-diameter axle bearings.

The S60 we tested came from Strange, equipped with 3.54:1 gears, a Trac-Lok limited slip, a 1350-sized pinion yoke, and 7/16-inch wheel studs to match the other two housings. The four-bolt axle retainer flange also secures the axles, making it easy to pull an axle without removing the rear cover. The only modification we had to perform was the machine work necessary for the same larger center hole in the backing plates on the 12-bolt. This S60 rearend assembly and 1350 U-joint also required a new driveshaft, which we got from Strange.

DESCRIPTION PN SOURCE PRICE Strange S60 rear axle assembly PRSA05 Strange Engineering $2,098.39 Strange S60 A-body housing H1100AB Strange Engineering 769.00 Strange 35-spline S/T axles P3504 {{{Summit}}} Racing 371.00 Strange Dana 60 3.54 gearset D3550 Summit Racing 259.99 Strange Dana 60 Trac-Lok D3539 Strange Engineering 465.00 Strange Dana 60 aluminum rear cover D3509 Summit Racing 208.39 Strange Chevelle rear adjustable shocks, pair S5264 Summit Racing 305.{{{90}}} pair Strange aluminum S60 cover OPRS06 Strange Engineering 119.50 Strange driveshaft U1699 Summit Racing 219.95 Strange TH400 slip yoke, 1350 U1600 Summit Racing 99.95 Amsoil 75W90 synthetic gear oil, qt SVGQT Amsoil 11.85Rear Axle Specs

Here's a case for bigger is better, at least in terms of strength. Larger-diameter ring gears, axles, and pinion shafts all constitute stronger components. Basically, the greater the spline count, the larger the shaft minor diameter, which is the diameter of the shaft at the base of the splines.

One big strength advantage of the Dana/S60 is its 35-spline axles that measure 1.50 inches in outside diameter at the splines. Compared to the spindly, 30-spline 12-bolt axles, the S60 axles are massive.

One big strength advantage of the Dana/S60 is its 35-spline axles that measure 1.50 inches in outside diameter at the splines. Compared to the spindly, 30-spline 12-bolt axles, the S60 axles are massive.

The weakest link in most stock rear axle assemblies (with the exception of the Dana 60) is most often the axle spline count. In this chart, you can see that the stock Ford 9-inch and 8.8 axles are the smallest, which is where you can easily increase strength by upgrading to 31- or 33-spline axles. Moser offers a simple formula for determining torque capacity. Just plug in your engine's peak torque number and do the math: engine torque x first gear ratio x rear gear ratio x gear efficiency = torque to both axles. 500 lb-ft x 2.48 x 4.10 x 0.90 = 4,575 lb-ft total torque.

The following chart from Moser lists the torque capacity for one axle and recommends choosing the smallest spline count that will do the job. Since torque is applied to both axles, choosing the smallest 30-spline axle for the above example means we have a total load capacity of 12,400 lb-ft, which offers an excellent margin of safety.

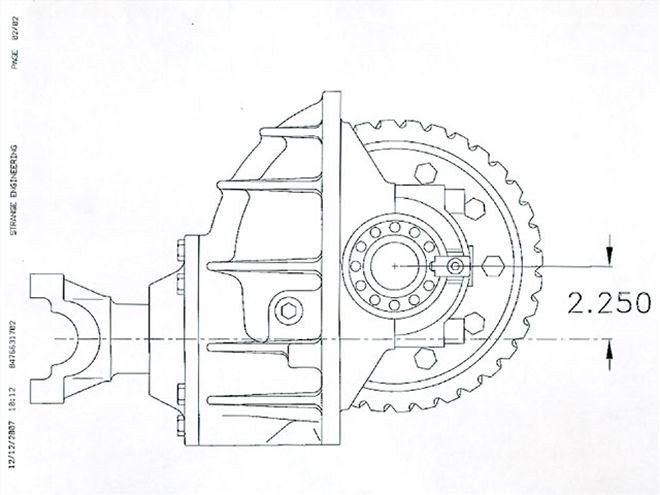

Spline This Strange Engineering drawing of a 9-inch rear gear assembly clearly illustrates the relationship of the pinion to the ring gear and hypoid offset. The closer the pinion is to the ring gear centerline, the less power is required to turn the gearset.

This Strange Engineering drawing of a 9-inch rear gear assembly clearly illustrates the relationship of the pinion to the ring gear and hypoid offset. The closer the pinion is to the ring gear centerline, the less power is required to turn the gearset.

Hypoid Offset

What the hell is that? This dimension is defined as the distance between the pinion gear and ring gear centerlines (see illustration). If the pinion gear were placed directly in line with the ring gear centerline, the hypoid offset would be zero, and this would really be a bevel gear rather than a true hypoid. All automotive rearend gears are a hypoid design because the pinion gear is positioned below the centerline of the ring gear to increase tooth contact and strength. Since free lunches rarely occur in engineering, the cost of this increased tooth contact is greater sliding friction between the gear teeth.

The Ford 9-inch has the greatest hypoid offset, which means it should require more power to drive this ring-and-pinion set compared with a typical Dana 60 rearend that employs the least offset. When you look at the accompanying chart, you can see that the Dana 60 rearend appears to have an advantage based on both ring-gear diameter at a massive 9.75 inches and the smallest hypoid offset.

Ring Gear Diameters Hypoid Offset This comparison of a Dana/S60 9 3/4-inch ring gear to the 12-bolt's 8.875-inch overall diameter redefines the concept of big.

This comparison of a Dana/S60 9 3/4-inch ring gear to the 12-bolt's 8.875-inch overall diameter redefines the concept of big.

The Ratio Game

If you are looking for the broadest spread in gear ratios, the 9-inch has the field covered, but only slightly. Between factory and aftermarket ratios, the Ford spans from a Bonneville-busting 2.47:1 all way up to a tach-twisting 6.14:1. But even that isn't as deep as the S60's 7.17:1 rear cog. As a gear ratio becomes numerically larger (lower in terms of a ratio), the pinion gear diameter becomes smaller with fewer teeth. This reduces durability, which is when the 9-inch's pinion support becomes really important.

Break-In Procedures

Since all three of these rearends began life with new gears, each had to be properly broken in before testing could be performed. Each rearend was outfitted with a set of brakes, filled with typical gear oil, and installed in our Chevelle. Each rearend was then driven for 40 miles on the freeway to ensure the gears were completely up to temperature and then allowed to cool overnight. This break-in procedure was repeated three times for a total of 120 miles. Then we drained the gear oil from each rearend and refilled them with Amsoil 75W90 synthetic gear oil for the test.

We chose Amsoil's synthetic 75W90 gear lube for its strong lubrication properties and thermal stability after breaking in each of the three rearends with nonsynthetic gear lube.

We chose Amsoil's synthetic 75W90 gear lube for its strong lubrication properties and thermal stability after breaking in each of the three rearends with nonsynthetic gear lube.

Rearend Weigh-In

We measured each rearend assembly with and without brakes. The Strange S60 is the heaviest of the three without brakes, but only by 20 pounds compared with the 12-bolt. Considering the massive 35-spline axles, huge ring gear, and 3-inch-diameter tubes, we're surprised it doesn't weigh more. The same Chevelle/Camaro 9 1/2-inch drum brakes were used on both the 12-bolt and the S60, while the Ford employed much larger 11-inch drums. The Ford drum brakes add 64 pounds, while the 12-bolt GM brakes come in at 39 pounds. If we level the weight playing field by using the same weight for brakes on the 9-inch, the Ford's overall weight becomes 213, which is lighter than the S60 by 17 pounds.

Any rear axle assembly is considered unsprung weight, which is defined as weight not supported by the vehicle's springs. From a vehicle dynamics standpoint, minimizing unsprung weight is important. But for a typical street performance car, the difference among all three of these assemblies is less than 30 pounds, which is less than 1 percent of total vehicle weight.

This 383 has been in the car for several years and makes acceptable power. The Chevelle has run low 12s at 112 mph in this configuration with the 9-inch.

This 383 has been in the car for several years and makes acceptable power. The Chevelle has run low 12s at 112 mph in this configuration with the 9-inch.

Our Test Mule

A backyard full of Chevelles made the choice for a test vehicle easy. This small-block '66 is equipped with a GM Performance Parts HT 383 short-block beefed up with a Comp XE282 hydraulic roller cam (230/236 degrees at 0.050, 0.510/0.520-inch lift, 110-degree lobe-separation angle) with 9.5:1 compression. For cylinder heads, it has a set of TFS 215cc heads with an Edelbrock Performer RPM Air-Gap intake manifold and a Barry Grant Speed Demon 750-cfm carburetor. The headers are a set of 15/8-inch Hedman headers backed up with a Flowmaster 21/2-inch exhaust system muffled by a pair of 40 Series mufflers. Directly behind the 383 is a TCI TH400 automatic with a 3,000-rpm stall speed 10-inch converter. For rear tires, we're running a pair of 26x10.5x15-inch Mickey Thompson ET Streets mounted on 15x8-inch Center Line wheels. We also used a giant seven-blade engine-driven clutch fan for these tests to ensure the engine temperature remained consistent.

We checked pinion angle for each rearend by first removing the rear springs and then simulating ride height with the lower control arms at zero degrees.

We checked pinion angle for each rearend by first removing the rear springs and then simulating ride height with the lower control arms at zero degrees.

Test Day

Once all the rearends were assembled and broken in, we were finally ready for the actual dyno testing. This called for a trip to Westech to spin the company's SuperFlow in-ground chassis dyno to generate some accurate rear-wheel horsepower numbers for each rearend. The test procedure called for installing each rearend in our test Chevelle, bringing the rear axle up to 125 degrees F measured at the pinion bearings with a heat gun, stabilizing the engine coolant temperature at 180 degrees, and then running two pulls on the chassis dyno and averaging them into one run that would be plotted on a graph.

To establish the pinion angle, we measured the position of the pinion yoke perpendicular to horizontal. All three housings required different upper control arm lengths to create the same pinion angle for all three rearends. We used the Hotchkis adjustable upper control arms to equalize the pinion angle at 2 degrees nose down for all three rearends.

To establish the pinion angle, we measured the position of the pinion yoke perpendicular to horizontal. All three housings required different upper control arm lengths to create the same pinion angle for all three rearends. We used the Hotchkis adjustable upper control arms to equalize the pinion angle at 2 degrees nose down for all three rearends.

All three rearends required different driveshaft lengths to accommodate the various pinion positions and U-joints. We already had a driveshaft for the 12-bolt, and Strange built a driveshaft for the S60 rearend. That left us needing a driveshaft for the Ford 9-inch, which we got from Denny's Drive Shaft. The Chevelle was also equipped with tubular lower and adjustable upper Hotchkis control arms. By adjusting the length of the upper arms, we were able to maintain a common 2-degree nose-down pinion angle for all three rearends. This eliminated the pinion-angle variable, since all three rearends position the upper control arm mount in different locations.

As you can see from the accompanying comparison graph, from 3,500 to around 5,000 rpm, there is only a slight power difference between the 9-inch and the 12-bolt, while the S60 and the 12-bolt looked almost identical. We also expanded the curve in the second graph because it was interesting to see how the S60 performed similarly to the 12-bolt up until around 5,000 rpm, then fell off after 5,600 rpm, and actually dropped below the 9-inch power numbers at one point.

This may be due to the power required to spin the larger ring gear, but that doesn't account for the fact that it appears the curve is beginning to climb at the last data point. Send us your theory on that one. What is apparent is how much the 9-inch power curve drops off at the higher engine speeds. If we had used an engine with more rpm potential, the power difference may have been even greater at 7,000 rpm. The horsepower difference at 5,800 rpm was 13 hp between the 12-bolt and the 9-inch. At 324 hp for the 12-bolt, this is a difference of 4 percent at that specific data point. If we look at the overall average, the difference is only 2 percent between the 9-inch and the 12-bolt and virtually a push between the S60 and the 12-bolt.

What we've discovered is that there is definitely a rear-wheel power difference between a 9-inch Ford and the 12-bolt, which appears to be the difference in hypoid offset between these two rearends. Just for fun, consider that submitting a Ford 9-inch to either the Mikronite or REM gear-treatment process could improve the rear-wheel horsepower numbers. Car Craft did a test last year on a Ford 8.8 rearend ("Mikronite for Power," Jan. '07) using a Fox-bodied Mustang and saw a 6hp increase in rear-wheel horsepower by just treating the gears. When we brought this up to Ray Currie, he mentioned that he prefers the REM process, which creates a similar treatment to the ring-and-pinion gear surfaces that would no doubt produce similar results. That would put the 9-inch on equal terms with a 12-bolt-unless you did the same mod to the 12-bolt. The cost for the Mikronite process on a ring-and-pinion is $275.

Overall, we've learned that the 9-inch doesn't eat as much power as we thought, the 11-inch rear drum brakes for a Ford weigh a ton, the S60 isn't as heavy as we believed, and the 9-inch housing, gears, and axles are only 5 pounds heavier than a 12-bolt, which was a bit of a surprise. Add in the minimal power differences, and we've just placed another piece in the mosaic of the musclecar puzzle. Plus, as with any successful dyno test, it has created as many questions as it has answered. Now we're looking at that TH400 and wondering how much power it eats compared with a TH350. Hmm . . . .

Rear-Wheel Power Numbers

Average power is another way to look at the differences among these three rearend assemblies. As you can see from the chart, all three are very close in terms of peak and average horsepower and torque. The greatest difference is between the 12-bolt and the Ford 9-inch, with an average rear-wheel horsepower loss of 6.6 hp and 2.6 lb-ft of torque for the 9-inch. Since the average power takes into account the entire run, this represents only a 2 percent rear-wheel horsepower difference between the 12-bolt and the Ford 9-inch. The power difference isn't very much, which means it would be difficult to measure in terms of lost e.t. among these three rearends. We'd expect the difference in performance on the dragstrip between the 12-bolt and the Ford would be measured in hundredths of a second. Now you know.