It used to be if you wanted disc brakes on a Tri-Five, you scrounged parts from a junkyard and bought roughly-made mounting brackets so your Shoebox could stop on a small piece of change rather than a dollar bill. And, the biggest you could get were the 11-inch discs that came on heavy-duty factory systems with single-piston calipers. Thankfully, those days are long gone!

Today, when someone wants to upgrade the brakes on their stock Tri-Five chassis, there is such a variety of kits to choose from it can leave your head spinning. Do you want single-, dual-, four-, or six-piston calipers? What size rotors do you want? Do you need a kit with drop spindles to get your stance lower? Do you want manual or power-assisted brakes? We could go on and on until you’re confused out of your skull, but you get the point.

You might recognize our 1955 210 sedan from when we ditched our dying 235 six-cylinder for an LS powerplant and 4L60E trans using a Classic Performance Products conversion kit. We then installed a CPP 500-series power steering conversion, and a 2-gallon CPP aluminum fuel tank. That left us with just one more thing to do for full roadworthiness and modern feel: disc brakes.

Looking at the options, we could’ve gone with a typical vacuum-assisted brake system, but we didn’t want a big power booster cluttering up the engine compartment, and we also didn’t want to have any sort of minimum vacuum requirements limiting us on any future engine mods. We also didn’t want to go with manual brakes, which could cause normal street driving and cruising to give our leg a heavy workout. So, that left us with the obvious choice, hydraulically assisted brakes.

CPP’s Hydra Stop system was designed for direct fit into a variety of classic applications and utilizes the power steering pump to supply the necessary hydraulic pressure for brake assist. So, if you’re running a radical cam profile that doesn’t leave you with a lot of vacuum, your brakes will still work just fine. And, you don’t have to clutter up your engine compartment with a vacuum reservoir.

The Hydra Stop system is compatible with any of CPP’s disc brake kits, and can be used in front disc/rear drum or front disc/rear disc setups. No firewall mods are needed, and the Hydra Stop assist unit is compact enough so you can still easily get to all of the spark plugs, remove the driver-side valve cover with no difficulties, and work on your engine a bit easier.

“CPP offers 100 percent brand-new hydraulic assist units, not remanufactured units that were pulled from a junkyard,” said CPP’s Javier Nunez. “They are designed with bolt-on mounting brackets and the proper linkage to connect to the brake pedal. We offer Hydra Stop systems in both entry-level and high-end, show-quality units, and complete or individual.”

The kits come with everything you need for a full four-wheel conversion, including necessary hard lines, flex lines, and hardware. CPP’s kits are designed for easy fit and installation. We had everything done at a leisurely pace over the course of a weekend, which means your Tri-Five won’t be off the road for very long. And the end result was our 1955 having the stopping power of a modern sports car, giving us better peace of mind when driving in traffic around town, and the knowledge that when we hit the dragstrip and autocross course, we’ll have no problems slowing things down.

1. Our 1955 sedan still had its factory, non-power assisted drum brakes at all four corners. These brakes might’ve been fine back in the day, but there’s no denying that in the modern world, they’re antiquated, ineffective, and in some cases dangerous.

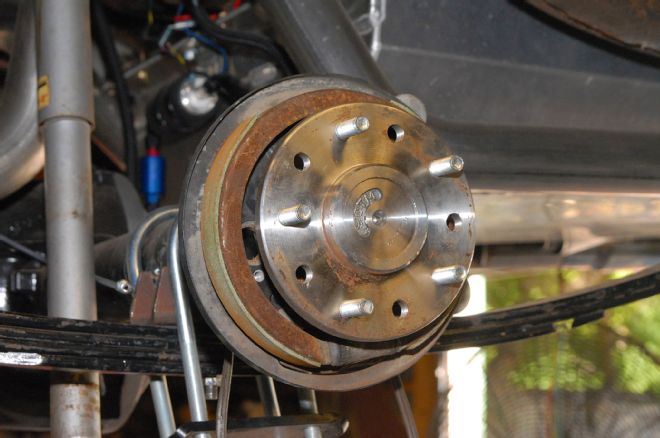

2. Out back, we already had upgraded to an 8.5-inch 10-bolt rearend with factory disc brake backing plates.

3. After supporting the lower control arm with a pole jack, we unbolted the original spindle from the upper and lower ball joints.

4. Next, we unbolted the tie-rod ends from the steering knuckles.

5. The last step before spindle removal is disconnecting the brake hose from the mounting point on the frame.

6. A few whacks with a hammer and the spindle came free from the ball joints.

7. Now is the perfect time to inspect your ball joints and replace them if necessary. Ours were in great shape, only the dust boots needed replacing.

8. The CPP Hydra Stop system comes preassembled on CPP’s Tri-Five 2-inch drop spindles. This gives us more stopping power and a lowered stance that will improve handling and looks. All you have to do is bolt it up to the ball joints, just like the factory spindle.

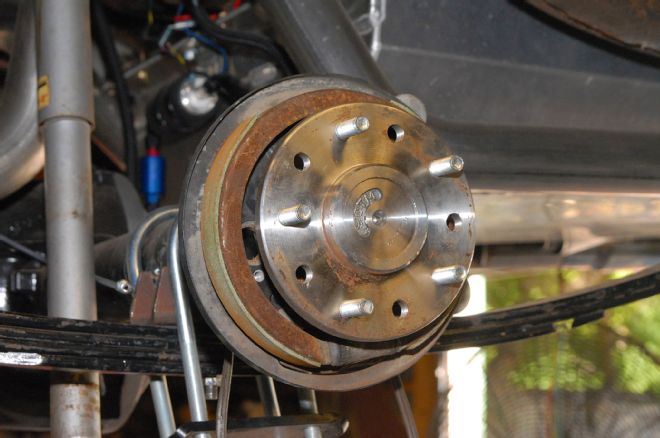

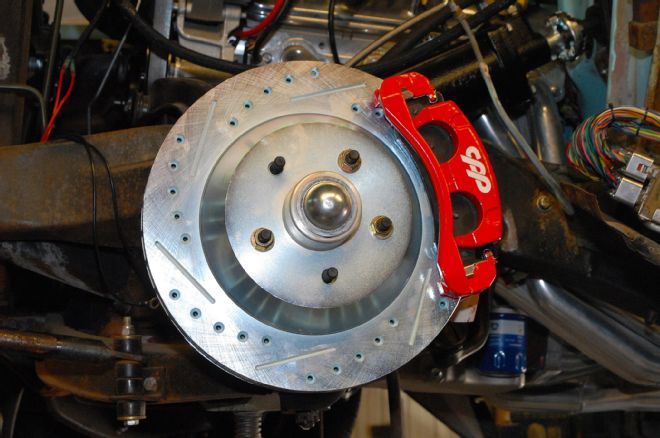

9. CPP’s Hydra Stop brake system utilizes heavy-duty twin-piston production calipers from the Hummer H2. Not only do these calipers provide an enormous amount of clamping force, when the time comes for replacement pads you can visit any local parts store. We had already modified a set of 18-inch fifth-gen Camaro wheels to fit our ’55, so we had no trouble with caliper clearance. This big-brake kit requires a 17-inch minimum wheel diameter for clearance between the wheel and caliper.

10. One thing you’ll need off the old factory spindle assemblies is the steering knuckles. We unbolted ours, then cleaned them up and gave them a fresh coat of black paint before bolting them onto our new CPP spindles.

11. The rotors in our CPP kit come drilled and slotted, with directional internal cooling vanes for increased heat dissipation. The drilling and slotting helps to prevent outgassing of the brake pads under heavy braking from causing brake fade, due to gas buildup between the surface of the rotor and the face of the brake pad.

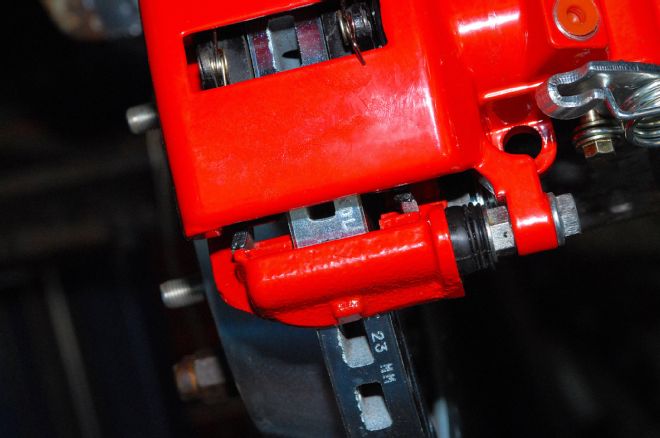

12. Our rear CPP disc brakes use Lincoln Continental emergency brake style calipers that are a single-piston design. This setup is more reliable than systems that use a pair of small shoes that run on the inside of the rotor for the emergency brake.

13. To install the rear discs, first the axles have to be removed from the rearend, followed by the later-model GM rear disc backing plate.

14. The CPP rear disc kit uses mounting brackets that bolt right to the axle flange. Shims are included to help center the caliper on the rotor.

15. There’s no set starting point for the rear caliper shims, so the best way to start is throw a couple of them on the mounting bracket, bolt the caliper in place, and check the location of the brake rotor inside the caliper. Here you can see the rotor is too close to the outside of the caliper, meaning we have too much shim thickness. We pulled a medium size shim out, bolted the caliper back on, and it was centered almost perfectly. Each side will be a little different and require some test fitting to find the correct thickness of shims for each side. Not hard at all to do, just requires a little patience.

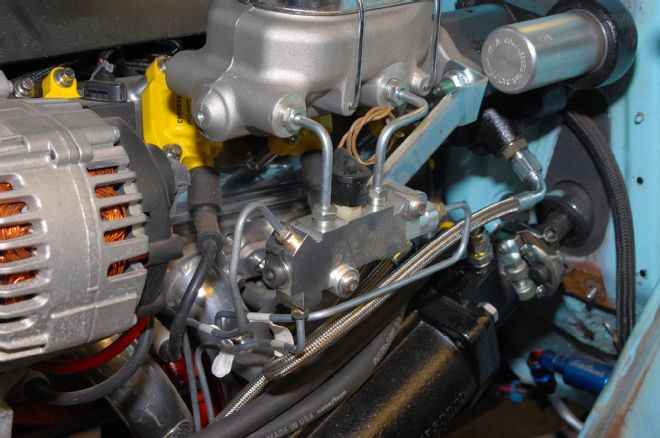

16. The real heart of our CPP Hydra Stop system is this beauty. Instead of using vacuum for brake assist, Hydra Stop uses hydraulic pressure from the power steering pump. There are numerous advantages to using a hydraulically assisted brake booster. For starters, the Hydra Stop unit is more compact than typical vacuum boosters, meaning they take up much less space in the engine compartment. Second, not using engine vacuum means camshaft selection for your engine isn’t limited by vacuum output, nor will you have to install an unsightly and space hogging vacuum reservoir. And finally, it just looks more attractive.

17. The CPP Hydra Stop unit mounts to the firewall using the original master cylinder’s four mounting studs.

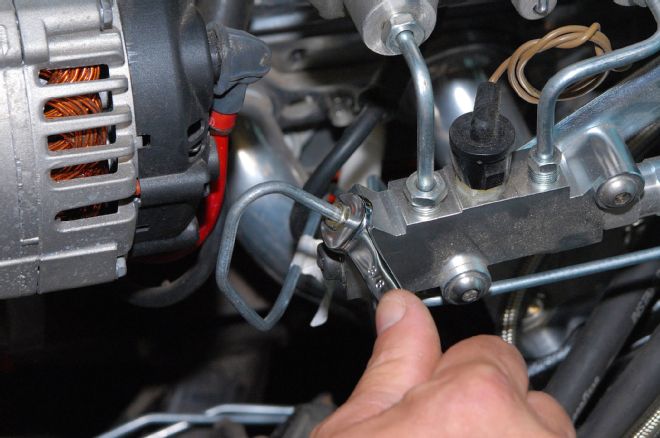

18. Next was hooking up the hard lines from the frame to the included, four-wheel-disc-calibrated proportioning valve. CPP sells prebent hard line kits for Tri-Fives and a variety of other Chevys, so you don’t have to spend time bending, cutting, and flaring lines to fit. They’re available in factory original style or stainless steel.

19. With the Hydra Stop unit secured, we could plumb the hydraulic lines to feed the system. Pressurized hydraulic fluid flows from the power steering pump to the steering box, then from the steering box to the Hydra Stop unit, using the included cut-to-length braided steel high-pressure power steering lines.

20. Both the included high-pressure lines and return lines for the system are cut-to-fit, so you’ll need to do some mocking up to figure out your routing and line length, then use masking tape to mark off where you need to cut. The tape also helps keep the steel braid from fraying while cutting.

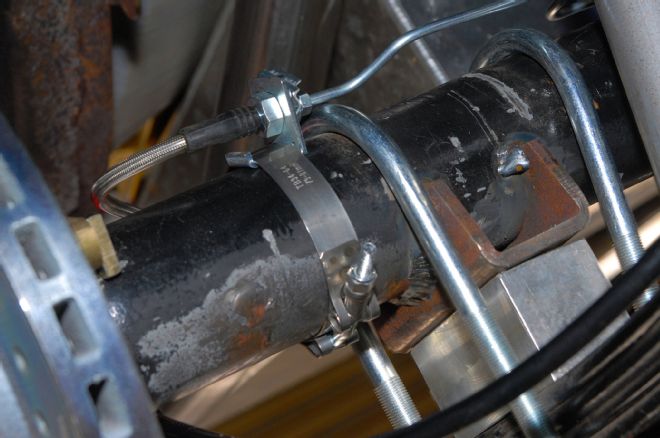

21. The kit includes an inline fluid filter that goes in the main return line after the T-fitting that connects the returns from the Hydra Stop unit and steering box. The filter prevents any sort of harmful debris from being sucked into the power steering pump and damaging it.

22. Here’s how the return lines will look once they’re trimmed to the proper length. All that’s left is to hose clamp them in place and connect our main feed line to the power steering pump.

23. So we could use the emergency brake function of our new rear calipers, we grabbed one of CPP’s rear disc emergency brake cables, (PN 5557EBC). This cable is made to connect to the factory e-brake cables, so we can use the stock e-brake handle inside the passenger compartment. The two cable ends attach to the calipers, and are secured with retaining nuts. Then, the whole cable assembly connects to the front pull cable.

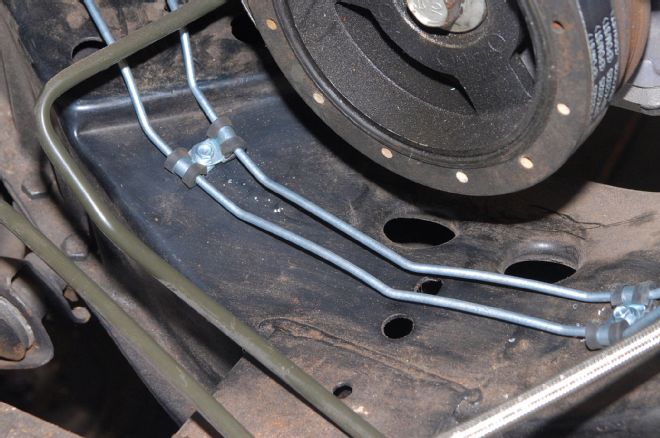

24. To connect the hard brake lines on the rearend to the main frame mounted line, we picked up CPP’s Tri-Five-specific rear brake hose, (PN RSFLK-316).

25. The CPP rear disc conversion kit includes these mounting brackets that clamp onto the axletubes and hold the couplers in place for the rear brake lines and hoses.

26. The CPP brake line kit includes the main lines that feed the right side of the car and the rear. They’re also prebent and already the proper length, so all you have to do is feed them along the frame and secure them in place.

27. The Hydra Stop unit comes with the correctly calibrated proportioning valve (for either front disc/rear drum or front disc/rear disc) installed and ready to go. It even has the wire in place to hook up to the brake light.

28. The last step is hooking up the factory brake pedal to the Hydra Stop actuation rod. This was an easy process, and the rod lined up perfectly with our pedal. Sometimes this isn’t always the case, so CPP includes the parts and pieces needed for adjusting the pedal and/or actuation rod to get everything hooked up correctly.

29. And there you have it. We’ve gone from the sweat-inducing, hold-your-breath-and-pray drum brakes, to hard-clamping, sure-stopping discs that can take spirited street driving, high-speed dragstrip passes, and heavy-footed autocross fun. These look so good, it’s almost a shame to cover them up with wheels!