Just when we thought we were all set to make some passes in our 1968 Plymouth Valiant at the drag strip, we discovered an impediment to our progress from a fatal error of our own making. Our wheel studs were mangled and we couldn't get the lug nuts off to bolt on our new M&H slicks. After finding the perfect sticky tires, getting the track date arranged, and driving all the way out to the track at 7 am, we were stuck in the pits with two lug nuts that would only budge a few threads before locking up. Major bummer!

We don't know exactly what happened or who did it, but the likely cause was an exuberant rookie at a tire shop with a powerful impact gun and dreams of becoming a NASCAR tire changer. Two lug nuts on one side of our built Strange S60 rearend were seized as a result of inserting the lug nut into the impact socket and pounding the impact gun hard into the stud. Sometimes this stunt works, but more often it's an epic cross-thread failure. We needed to replace those studs with new ones before returning to the track—or even being able to change the rear tires—so we figured why not document it here for future reference? If nothing else, it will give you the chance to see some of Strange Engineering's severe-duty hardware up close.

Aftermarket screw-in studs vary from factory press-fit studs in a couple key areas; they're much easier to replace on the fly, and they're a lot more secure (and safe!) once attached to the axle flange. Quite often, screw-in studs are also built in small, high-quality batches for the racing industry so that they will exceed OE strength standards for added safety. Strange's line of SPC-sourced grade-8 studs fall well into that category. Check out the wheel stud swap on our Strange Engineering S60 rearend as performed by the Mopar experts at Motech Performance in Murrieta, CA.

1 Our Strange Engineering S60 rearend has 35-spline Strange Alloy axles that are made from SAE 1550 modified steel that's been induction hardened for torsional strength. All heat treating takes place before machining so that the strength is locked in. We'll never break one of these with our 500-inch Indy-built low-deck wedge motor, but we did put a hurting on the wheel studs from basic stupidity. Thankfully, they're screw-in ones!

2 Check out those mangled wheel studs! Getting the lug nuts off was a chore that involved overnight soaking in penetrant, then wailing on them with a quality impact gun attached to a compressor with a large reserve air tank. The lug nuts did eventually come off smoking, but the stud threads and lugs were trashed. We were just glad we didn't have to resort to the acetylene torch. The lesson: don't let anybody else bolt wheels to your hot rod!

3 Strange sells complete S60 axle packages with Wilwood Dynapro brakes—such as the ones on our Valiant. To gain access to the axle, you need to pull the caliper off and pull the rotor hat.

4 Here, Jason Muckala of Motech Performance is comparing the length and thread pitch of the original Strange wheel studs with some new Strange screw-in studs he already had in inventory. (You don't want to mix and match thread pitch, or length, even in a pinch). Strange sells a variety of high-performance screw-in and press-in wheel studs which typically run $90 for a set of 10.

5 Because our stud threads were so mangled, Jason opted to use a cut-off wheel to lop off the worst part of each stud. This made it easy to unscrew the bad studs once the axle was out of the rearend housing.

6 Strange screw-in wheel studs are grade-8 fasteners, as indicated by the six raised hash marks on the bolt head. This indicates quenched and tempered medium carbon alloy steel with a minimum of 120,000 pounds of yield strength and 150,000 pounds of tensile strength. Our axles and wheels required studs with a half-inch diameter and 1 ¾-inches of length.

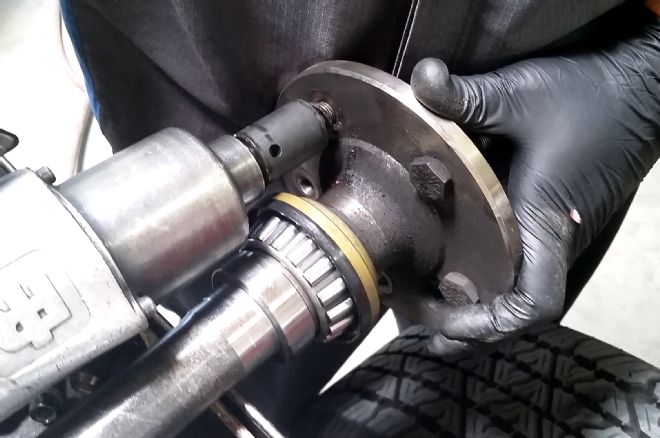

7 With the brake rotor off, you can access the retaining nuts for the housing end (we had our S60 built with the big Torino housing ends) through the axle flange's access hole. (Note: if you order Alloy axles from Strange, machining for the access hole is an extra $40. Well worth it on our opinion!) The S60 has no c-clip axle retainers, meaning the axle slides right out once the retaining plate is unbolted.

8 This shot shows how the right side of the axle was elevated slightly with a pole jack during axle removal. This kept the fluid in the rearend where it belonged, and without making a stinky mess. Since the author changed the left side wheel on the previous "pit stop," the lugs and wheel studs were fine on that side. Three years after Strange technician John Kwas built our S60 rear, it was still in perfect mechanical order.

9 The wheel studs screw in from behind the axle flange on the 35-spline Strange Alloy axles. With the trashed section of threads already cut off, this operation was easy, and most importantly, there were no damaged stud threads to wreck the pristine threads in the axle flange.

10 Before screwing in the new Strange wheel studs, Jason gave the axle flange around the stud threads a good cleaning with some brake cleaner. This is also a good shot showing the Strange Alloy axle's optional housing end access hole.

11 You'll want to give each new wheel stud a shot of thread-locking compound—Jason likes the red Permatex. Note the hardened washer that goes between the axle flange and the bolt head.

12 Here's a quick shot during the axle installation we wanted to show you: We love how easy it is to swap pads on Wilwood's Dynapro caliper. A retaining wire is held to the caliper by a threaded bolt. Removing the bolt and the wire retainer gets you quick and easy access to the pads.

13 On any hi-po track car—even with steelies—you always want to manually torque down your lugs. It's also a good habit to put a dab of anti-seize compound on the threads at the first opportunity. This will make it easy to get lug nuts on and off, and it will prevent future damage including corrosion. With anti-seize, we dropped our torque down to 85 lb-ft because the lube increases the clamping load.