OK, so maybe the title is a bit of a stretch. We'll be leaving out some turbo-oriented stuff, like diesel truck applications and other junk you couldn't care less about. And there will be no A&E-style The Life biography on Galen Tomlinson, otherwise known as Turbo on American Gladiators. But if you're thinking about adding a turbocharger to your engine, or upgrading your car's factory turbo, we've got some good information here, culled from a number of experts in the turbocharging industry. They shared their thoughts and opinions about how to choose the right turbocharger, engine upgrades you should consider in addition to the turbo, and some highly recommended accessories that'll help you get the most from your new boost levels.

Choosing a Turbo

Our hands-down favorite quote about turbo selection came from Tyler Tanaka, marketing manager for Turbonetics. "It's like buying shoes," Tanaka explained. "You don't just go to the store and order a pair of shoes that are too big for your feet. The turbocharger has to be the right size for your application." (Tanaka has also been known to say, "I like buying shoes...women's shoes." But that doesn't seem too relevant to the topic at hand.)

So, as sexy as that huge snail would look under the hood, it may not be right for the kind of driving you do. It's true that a bigger turbo will produce more air volume, which translates to higher levels of peak power. But the bigger turbo takes a lot of exhaust pressure to make that boost, which translates to a ton of turbo lag.

Now, lag isn't necessarily a bad thing, if you're a drag racer. "On a front-drive car, turbo lag is your friend," said Jensen Oda of A'PEXi. "You sacrifice power in first gear, but in second through fifth you will always have power when shifting the gears. The last thing you want is a turbo that spools up too quickly in first gear, 'cause the tires will just go up in smoke, which usually ends up smoking second, and finally bogging in third."

But that's racing. "Bigger is not always better if you aren't going to race," said "White" Mike Liao of Blitz. On a street car, when you're not always at wide-open throttle (at least, we assume you're not all the time), drivability is more important than peak power. For that extra power punch at the midrange, go with a smaller turbo that'll spool up quicker.

| Heard the term "ball-bearing turbo"? That means the center shaft between the turbine and compressor blades rides on ball bearings instead of thrust bearings. The ball bearings reduce friction, so spool-up time is quicker, but they are costly to rebuild if they're damaged. All A'PEX Integration turbos, like this AX75 model, utilize ball-bearing technology. The AX75 is A'PEXi's largest single turbo, capable of enough boost to support 650 hp.

| Heard the term "ball-bearing turbo"? That means the center shaft between the turbine and compressor blades rides on ball bearings instead of thrust bearings. The ball bearings reduce friction, so spool-up time is quicker, but they are costly to rebuild if they're damaged. All A'PEX Integration turbos, like this AX75 model, utilize ball-bearing technology. The AX75 is A'PEXi's largest single turbo, capable of enough boost to support 650 hp.

For a lot of you, choosing a turbo will be as simple as opening a catalog or going online and picking the right kit for the kind of car you drive and the way you drive it. Almost all of the turbo companies we talked to offered complete turbo kits, which have been assembled after lots of R&D time. "Leave it up to the experts," said A'PEXi's Oda. "The last thing you want to do is experiment on your daily driver."

But what if there's no kit for your car? Where do you begin? "Do all the basic stuff first: headers, plumbing, fuel, ignition, so the car is as good as it can be," said Turbonetics' Tanaka. "Then sit down with one of the turbo manufacturers and go through the engine's parameters."

Questions to ask the turbo maker include how much horsepower are you interested in? How much boost? At what rpm do you want peak power? What kind of transmission are you using, what kind of torque converter or clutch? Also discuss non-engine related stuff, like what sort of conditions you drive the car in. If you're in Denver's thin air, you're going to need a different setup than a guy in LA or Long Island.

With that kind of information, said Tanaka, "a company will choose a turbo unit that's personalized for your car and how you drive."

Turbocharging Basics

Turbocharging is one type of what's called "forced induction." A turbo is an air pump that pushes compressed intake air into the combustion chambers. This charge is far denser than the air that would normally flow into the cylinders due to atmospheric conditions. When the denser air charge is combined with a greater-than-normal amount of fuel, it will create a more powerful burn, which exerts greater pressure on the pistons and therefore increases the engine's power output.

Inside a turbocharger is a shaft with finned wheels at each end. One wheel, called the turbine, is driven by exhaust gases leaving the engine. The exhaust flowing past the wheel causes it to spin, which in turn spins the wheel at the other end of the shaft, called the compressor. It's the compressor's job to take fresh air and pressurize it before sending it down the intake tract to be mixed with the fuel.

Turbocharging has a couple of advantages over supercharging, the other form of forced induction. Because a turbo has no mechanical link to the engine (like a supercharger's drive belt and pulleys), there is no parasitic drain in power to drive it. Additionally, freewheeling turbochargers aren't limited to or by engine rpm. Plus, turbos are designed to produce boost at higher engine speeds than a supercharger, which makes them well suited to high-revving sport compact engines.

Engine Upgrades

All our experts agreed that it's far easier to upgrade a car that came from the factory with a turbocharger than to add a turbo to a car that didn't originally have one. And that's not just because the turbo, brackets, and necessary plumbing are already in place. More importantly, the engine components that are vulnerable to damage due to high boost pressures-head gaskets, pistons, rods-should already be stouter in a car originally equipped with a turbo.

That doesn't mean a naturally aspirated engine will automatically grenade when you bolt on the turbo, though. "If you're mounting a well-designed kit, and you're keeping [it] at lower boost levels, you shouldn't need many internal upgrades," said Mike Chung of GReddy's R&D department.

The definition of "lower boost levels" depends on who you're talking to and the vehicle you're discussing. To Chung, low boost means 5 1/2 psi for an older SOHC Civic, and 7 to 7 1/2 psi for an Integra. But we also heard 10 and even 15 psi quoted as "low" and "street-oriented" boost. As with so much of this stuff, discuss your application in depth with your turbo maker of choice to determine the appropriate amount of boost for your car.

No matter how much boost you're shooting for, one mod you must make is to increase the amount of fuel going to the cylinders. If you don't add more fuel to burn with the denser compressed air charge that's coming from the turbo, not only will the engine not make more power, but it could experience detonation and possibly burn pistons. And speaking of preventing detonation, be sure to switch to premium fuel if you haven't done so already.

There are all sorts of methods of feeding more fuel to a turbocharged engine. Some are electronic, like altering the fuel map in the stock ECU or piggy-backing a fuel-control unit to the stock computer. Plumbing changes can be made, too, like adding a fuel-pressure regulator (some are boost-sensitive), high-flow fuel injectors, and more powerful fuel pumps. But no matter how you do it, "additional fuel enrichment is the key to producing safe power for any turbocharged application," according to Willie Yee of HKS.

| Turbocharging is one area where size definitely matters. The Turbonetics turbo on the right develops enough boost for about 200 hp; the one on the left is good for 1,800. Like other turbo makers, Turbonetics can recommend-and build-the right turbo system for your application.

| Turbocharging is one area where size definitely matters. The Turbonetics turbo on the right develops enough boost for about 200 hp; the one on the left is good for 1,800. Like other turbo makers, Turbonetics can recommend-and build-the right turbo system for your application.

After fuel, compression ratio is next on the to-do list, especially when adding a turbo where there wasn't one before. A compression ratio (c/r) of 9.5 or 10:1, typical in a naturally aspirated car, will produce cylinder pressures that are way too high when there's compressed air flowing into the chambers. Instead, a turbo motor wants a c/r in the 8 to 8.5:1 range. Dropping those c/r points can be as easy as installing a thicker head gasket, though if that won't do it you may need new, dished pistons. If you have to replace the head gasket, a metal one will withstand more boost than a composite gasket. If you're replacing pistons, be sure the new ones are forged, not cast.

Most of our experts agreed that, beyond pistons, there's no need to upgrade the rest of the reciprocating assembly if you're running mild (7 to 10 psi) boost levels, though GReddy's Chung and Turbonetics' Tanaka said they've found that Civic rods are more prone to snap than others. "In an Integra, for example, the piston ring lands will give before the rods go," said Chung.

The engine's ignition might need some work. "You'll want to retard the spark at the top end to avoid detonation," said Craig Gibbs, an applications engineer at Garrett who races a turbocharged Volkswagen in his spare time. Added Tanaka, "Some cars have great ignition systems, while others may need an aftermarket box, like an MSD unit, to help with the spark."

| Heat is a turbo system's number-one enemy, and you can see why. The exhaust gases that drive the turbine wheel are incredibly hot, so the turbine side of the turbo has to be built from heat-resistant metals, like cast iron (for the housing) and Inconel (for the turbine blades).

| Heat is a turbo system's number-one enemy, and you can see why. The exhaust gases that drive the turbine wheel are incredibly hot, so the turbine side of the turbo has to be built from heat-resistant metals, like cast iron (for the housing) and Inconel (for the turbine blades).

Gibbs also noted that, while using the right camshaft in a turbocharged engine is critical to its performance, "there are a lot of opinions out there about camming. It depends on what you want to do." For solid, all-around performance on the street, Gibbs recommends a cam grind that's mild enough to idle well and produce good vacuum, but one that also offers good mid-range power.

Gibbs had some plumbing advice, too. On the compressor side, he noted "you'll want the least amount of restriction and the biggest pipe the packaging will permit" to get all the compressed air efficiently into the cylinders. Use the diameter of the compressor inlet as a guide for pipe diameter.

On the turbine side of the turbocharger, "get the turbine as close to the head as possible to make it easier for the exhaust pulses to get to the turbo," Gibbs said. Also, you want a large-diameter downpipe from the turbine outlet to the catalytic converter to reduce backpressure that might slow the turbine down.

| Some think only serious boost levels require an intercooler, but our experts felt that even systems putting out 7 to 10 psi would benefit from the addition. By cooling the air after it leaves the compressor, it becomes denser, so more air can be packed into the cylinders. This is an A'PEXi Hybrid Intercooler, which uses different-shaped fins top to bottom to channel air for maximum cooling.

| Some think only serious boost levels require an intercooler, but our experts felt that even systems putting out 7 to 10 psi would benefit from the addition. By cooling the air after it leaves the compressor, it becomes denser, so more air can be packed into the cylinders. This is an A'PEXi Hybrid Intercooler, which uses different-shaped fins top to bottom to channel air for maximum cooling.

Turbo Accessories

Top on the list of items you should add to a turbo system is an intercooler, said most of our experts. A few, in fact, considered an intercooler mandatory at 7 to 10 psi. "That much boost will heat the intake charge," explained Gibbs. "You may have problems keeping the intake cool without an intercooler."

A blow-off valve was next on the accessory list, ranking higher than a boost controller. Why? Compressor surge, caused by excess pressure trapped between the compressor wheel and the throttle plates, can flow back to the turbo and "shock" it, said GReddy's Chung, which will impact the turbo's bearings. Blitz's Liao added that even if a factory turbocharged car came with a blow-off valve, it's a good idea to replace it with an aftermarket unit, since the OE valve won't handle as much pressure as an aftermarket valve will.

On the exhaust side of the turbo, wastegates fall into two types: internal (sometimes called integral) and external. Which you use will depend on several factors. Generally the external 'gates can handle greater pressures, as they're physically larger than the internal units. But if underhood space is tight, an internal wastegate may be the better choice. Another wastegate tip from Gibbs: An adjustable wastegate, whether it's internal or external, will allow you to tailor pressure relief-and therefore boost levels-by changing the rate of the valve's spring.

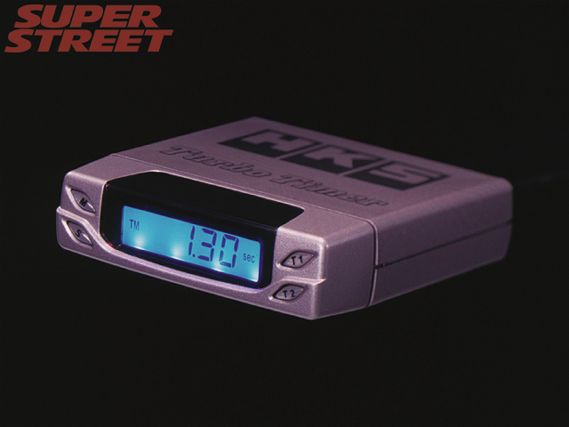

| A turbo timer allows the engine to continue to run, even after the ignition is turned off, so that oil can flow through the turbo and cool it. If hot oil is left in the turbo housing it can solidify (called "coking"), which will leave deposits on the turbo bearings.

| A turbo timer allows the engine to continue to run, even after the ignition is turned off, so that oil can flow through the turbo and cool it. If hot oil is left in the turbo housing it can solidify (called "coking"), which will leave deposits on the turbo bearings.

Another accessory that made it on several of our experts' lists was the turbo timer. This device automatically keeps the engine running, even if the key is turned off, to allow the turbo to cool before engine shut-off stops the flow of oil through the housing. If you don't properly cool a turbo before turning off the engine, the hot oil can coke, or solidify, around the turbo's bearings.

In the end, no matter what kind of engine upgrade or turbo accessory you've put on your car, "the whole turbo system is only as good as its weakest link," said Tanaka. "You won't see the engine's full potential unless the entire system-fuel, ignition, intercooler, intake, and so on-is optimized." There are lots of components that contribute to the overall performance of a car, not just a turbocharger. If any one of those pieces isn't up to the task, the most expensive or exotic turbo kit in the world won't get you where you want to be.

| Turbo Tech - All About The Turbo

| Turbo Tech - All About The Turbo

Used Car Buying Tips

Let's face it: There aren't that many turbocharged cars coming from the factory any more. So if you're looking for a ride with a turbo as original equipment, you're probably going to have to buy one second- or even third-hand. How do you avoid buying junk?

Here are a few tips:

·Stay away from high-mileage cars. Ditto cars that have already been heavily modified, so you don't have to worry about the quality of someone else's work.

·Check for oil leaks from the turbo. If you see blue exhaust smoke after the car has warmed up, chances are good there's a leak in the shaft seals. Another way to check: Disconnect the pipe from the compressor and wipe inside.

·Another oil tip: Since oil is the lifeblood of your engine (and especially the turbo), check the condition of the crankcase oil. If it looks dirty or needs replacing, it might be a sign that the previous owner didn't take good care of the car.

·Pull off the compressor's inlet pipe and check for foreign-object damage to the wheel's blades. This is especially important if the car's air filtration system has been removed.

·With the inlet pipe disconnected, reach in and spin the shaft. It should easily turn by hand. Pull back-and-forth and up-and-down on the shaft to make sure the bearings are still healthy. There should be minimal play.

·Some OE turbos are water- and oil-cooled. Check for signs of rust around the water fittings. If rust gets inside the housing, it can ruin the turbo internally.

·Any signs of overheating could spell potential turbo trouble. White hair-line cracks on the exhaust manifold are a giveaway that the engine has been run hot and lean.

·A leak-down and compression test will alert you to sealing problems between the head and engine block.

·Even well-cared-for turbos may need replacing if they have enough miles on them. Try to buy the car after the previous owner spent the bucks on a new turbo.

Turbocharger Glossary:

A/R: A formula used to determine the size of the compressor and turbine housing configuration. The letters stand for Area divided by Radius, where Area is the cross-sectional area of the scroll (the finned wheel), and Radius is the shortest distance from the centerline of A to the centerline of the turbine shaft. The basic rule of thumb about A/R: A turbo with a smaller A/R value will spool up quicker and be more responsive, though it won't produce as much peak power as one with a larger A/R value. The turbo with the larger A/R value has the greater capacity to produce power, but will spool up slower and exhibit turbo lag.

Bar: A means of expressing air pressure, like psi. A measurement of 1.0 bar translates to 14.7 psi, which is equivalent to normal atmospheric pressure at sea level.

Bearings: The shaft between the turbine and compressor wheel rides on bearings inside the turbo's center housing. In a standard turbo those bearings are made of metal, and a thin film of oil separates the shaft from the bearings. These bearings do wear, but they can be rebuilt if damaged. Some turbos use ball bearings in the center housing instead of metal bearings, which reduces friction and speeds up the turbo's response time. Ball-bearing turbos are pricey to rebuild, though. If you damage a ball-bearing turbo, you may have to sell your sister to rebuild it.

| Turbo Tech - All About The Turbo

| Turbo Tech - All About The Turbo

Blow-Off Valve: A device used to release excess pressure in the intake system between the compressor wheel and the throttle plates, to prevent compressor surge. Also known as a Pop-Off Valve.

Boost: A measure of the air charge sent from the compressor to the combustion chamber, typically indicated in either pounds per square inch (psi) or bar.

| Turbo Tech - All About The Turbo

| Turbo Tech - All About The Turbo

Compressor: The finned wheel on the intake side of the turbocharger that is driven by the exhaust-side turbine. It sucks fresh air through the center inlet, compresses it, and sends it to the combustion chambers. (Sometimes by way of an intercooler.)

Compressor Surge: A condition caused by compressed intake air caught between the compressor wheel and closed throttle plates. When you get off the throttle after a burst of acceleration, the plates close but the compressor wheel may still be sending compressed air into the system. If the compressed intake charge cannot flow through the throttle plates, it will flow back to the compressor, which could result in bearing damage.

| Turbo Tech - All About The Turbo

| Turbo Tech - All About The Turbo

Downpipe: The pipe that carries exhaust gas away from the turbine side of the turbocharger and into the exhaust system. A large-diameter, free-flowing downpipe eases backpressure that could impede the exhaust flow at the turbine and slow it down.

| Turbo Tech - All About The Turbo

| Turbo Tech - All About The Turbo

Housings: The snail-shaped enclosures inside of which the turbine and compressor wheels spin. Like A/R, housing shape and size have a tremendous effect on the turbocharger's output, as well as its ability to dissipate heat. A turbo with a larger housing can produce higher boost, and therefore higher horsepower, but is generally slower to spool. A turbo with a smaller housing spools quicker but cannot make high levels of boost.

| Turbo Tech - All About The Turbo

| Turbo Tech - All About The Turbo

Intercooler: A radiator plumbed into the air flow between the compressor and the intake manifold that cools the air coming from the compressor. A cooler charge of air is denser, so more of it can be packed into the combustion chamber. Intercooler design typically falls into one of two types-air-to-air or water-to-air-depending on what means is used to do the cooling. Air-to-air intercoolers are simpler, smaller, and lighter, though they may not cool as effectively as water-to-air units.

Pop-Off Valve: (See Blow-Off Valve)

Trim: A measure of the size of the compressor and/or turbine wheel.

| Turbo Tech - All About The Turbo

| Turbo Tech - All About The Turbo

Turbine: The finned wheel on the exhaust side of the turbocharger that is driven by the flow of exhaust gas coming from the engine and through the turbine housing. The turbine wheel drives the shaft that, in turn, spins the compressor wheel.

Turbo Lag: A hesitation in the production of boost. Lag is typically experienced with turbochargers with large housings or large turbine wheel sizes, as it takes more exhaust pressure to get the turbine spinning (spooled up).

| Turbo Tech - All About The Turbo

| Turbo Tech - All About The Turbo

Wastegate: A valve used to bleed off excess exhaust pressure on the turbine side of the turbocharger. This is done to maintain optimal boost pressure without over-spinning the turbine wheel. Wastegates are either internal (built into the turbine housing) or external (plumbed downstream of the turbo). Internal wastegates are found on most OE turbochargers, as they're less expensive to make and are easier to package underhood. Internal wastegates, however, are typically smaller than external versions, and so cannot relieve as much pressure as the external units can. Some wastegates can also be adjusted to tune boost levels.