Rotor Education - Tech Talk

Rotor Education - Tech Talk

We’ve received quite a few emails lately asking us to explain what the advantages are of cross-drilled and slotted rotors, as compared to the blank rotors most cars come standard with. We’ve also had requests to explain why many slotted rotors these days have curved or J-hook shaped slots, rather than straight slots. Rather than giving you the Wikipedia answer, we went right to the source by once again contacting Mark Valskis at Brembo North America (some of you will recall his contribution to the big brake kit Tech Talk story in the May ’11 issue).

|

The classic cross-drilled rotor is still a very popular and effective design found standard on high-performance vehicles like the Nissan GT-R.

|

The classic cross-drilled rotor is still a very popular and effective design found standard on high-performance vehicles like the Nissan GT-R.

As most of you already know, the basic function of a brake disc is to provide a mating surface for the brake pads so that when you stomp on the brake pedal the friction material that makes up the pad is squeezed against the rotors (by the calipers), converting forward motion into heat as the car slows. That heat is then radiated to the atmosphere as air flows over and through the rotors (and the rest of the braking system), completing the conversion of kinetic energy into thermal energy.

According to Mark at Brembo, cross-drilled rotors came into being because of the need to evacuate gases or water from the interface between the disc face and the brake pad surface. As Mark further clarified, “Modern brake pads don’t have an issue with out-gassing like they did many years ago, but the cross-drilling is still helpful for use in wet conditions, especially when the pad surface area is large. Additionally, cross-drilling increases the surface area of the disc, and this aids in disc cooling (one factor in brake disc cooling is the ratio of surface area to disc mass). The most significant feature of the holes (when done correctly) is that they continually refresh the brake pad surface, providing improved performance and greater disc life. As the holes pass the brake pad they essentially clean the surface, helping to prevent pad glazing or hardening. This effect can be easily observed on a drilled disc near the outer edge where there are no holes. In this area, the pad surface is not refreshed and you will typically see greater disc wear in this unswept area.” It’s also worth noting that this type of pad refreshing by cross-drilled and/or slotted rotors helps maintain more consistent frictional performance.

Some of you may not be fans of cross-drilled rotors because you’ve seen cracks in the disc surface radiating out from the drilled holes, but as Mark points out, not all drilled discs are created equally. “Brembo has a long list of requirements for drilled discs. First, the holes are not just simple cylindrical holes. They have a more complicated shape that requires special tools to create. We also have strict requirements on hole density or the number of holes per given surface area of the disc. Additionally, there are requirements for the hole size and placement of the holes, including distance between holes, distance from braking surface edges, distance to disc vanes, angular offset of holes and more.”

|

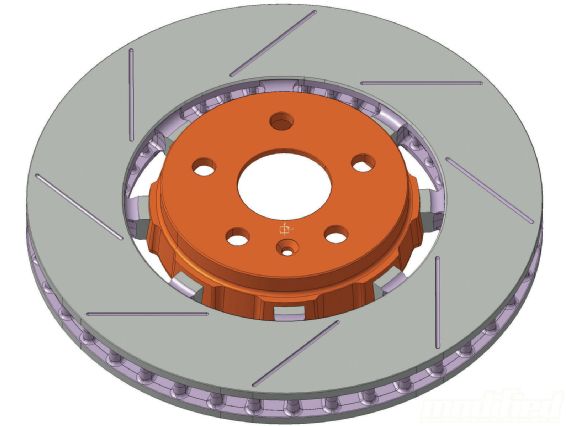

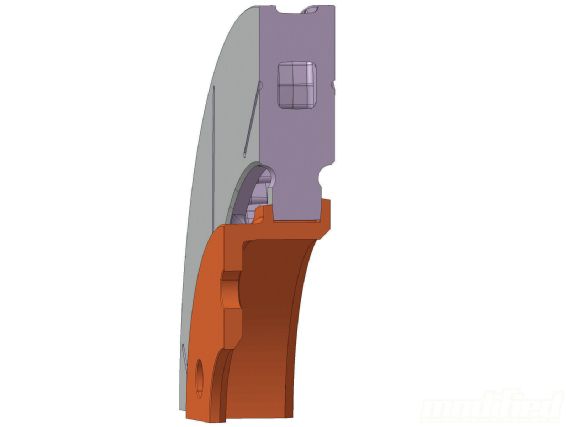

These CAD drawings of a slotted and ventilated Brembo brake disc illustrate just how complex the design of a modern high-performance rotor really is.

|

These CAD drawings of a slotted and ventilated Brembo brake disc illustrate just how complex the design of a modern high-performance rotor really is.

But even with the highest quality cross-drilled discs, there can be issues with thermal shock and fatigue around the holes when using very aggressive racing brake pads. As Mark explained, “Slotted discs were developed to provide the benefit of refreshing the pad surface, while being able to be used with top-level racing friction materials. Drilled discs provide the same benefit [refreshing the pads], but also increase the cooling of the brake disc. With top-level racing materials, the heat input is very rapid and the increase in localized cooling around the holes can cause issues.” So slotted rotors were developed as a solution to a very specific problem associated with extremely aggressive friction material normally associated with racing, though if you’re anything like me and run some pretty aggressive brake pads on the street as well as at the track, then slotted rotors may be the right choice for your car.

As for the shape of the slots, Mark had this to say: “The different design of the slots is due to extensive research and development, including [brake] dyno testing. Due to the fact that track testing is required, and thanks to strong collaboration with many top-level racing teams, Brembo has developed a very broad knowledge of the many different types of slot shapes possible when machining discs.” Since this type of extensive R&D is really outside the scope of all but the biggest brake system manufacturers, a lot of what you’re seeing in the aftermarket are companies copying what leaders like Brembo are doing with respect to slot shape, slot spacing, slot depth and so on.

|

These CAD drawings of a slotted and ventilated Brembo brake disc illustrate just how complex the design of a modern high-performance rotor really is.

|

These CAD drawings of a slotted and ventilated Brembo brake disc illustrate just how complex the design of a modern high-performance rotor really is.

Ultimately, the slots are all designed to do the same thing (refresh the brake pads), but different shapes no doubt impact the aggressiveness with which the pads are refreshed and also likely affect localized cooling of the disc. And speaking of cooling, the internal structure of ventilated rotors plays a very important role here. “The mass of the disc is the determining factor in how much energy the disc can absorb, while the design of the internal geometry helps improve the disc’s ability to shed the heat,” Mark explains. “The key factor in the use of a vented disc versus a solid disc is the increase in the ratio of disc surface area to mass. Heat transfer to the air occurs only on the surfaces of the disc that are directly exposed to air; so the more surface area, the better the disc can shed the heat.”

As for the internal vane structure of a ventilated disc, Mark adds: “There are limitless internal vane structures that are possible. Design of the vane structure has a dramatic effect on the performance of the brake disc. Some designs, such as directional curved-vane discs actually improve the airflow through the disc by turning the disc into a centrifugal pump. However, the cost of implementing this is increased due to the need for unique left- and right-hand discs. Brembo has patented a ‘pillar vane’ internal geometry that provides nearly all the airflow advantages of the curved vane discs while being able to use the same disc on both the left and right sides of the vehicle.”

|

This NASCAR braking system provides some interesting insight into disc slot design - note the curve of the slots to better evacuate water and brake pad material and how the slots get shallower near the inner and outer edge of the disc.

|

This NASCAR braking system provides some interesting insight into disc slot design - note the curve of the slots to better evacuate water and brake pad material and how the slots get shallower near the inner and outer edge of the disc.

Who knew so much technology goes into these seemingly simple iron discs (the material composition of brake rotors being a topic for another month). But when you consider just how vitally important the braking system is to safety and performance, it shouldn’t come as a surprise that industry leaders like Brembo are constantly looking for ways to improve the design of their brake discs.

Send your feedback to [email protected]

|

Rotor Education - Tech Talk

|

Rotor Education - Tech Talk