About the last place you want to find out that your 5.3L V-8 isn’t making the cut is in the mountains of Kentucky. But that’s just what happened to Greg Lovell, the owner of AntiVenom Racing (Seffner, Florida), while hauling a few cars up to the Holley LS Fest. He had been plotting a turbo kit to make his every day usage a bit more fun, as the truck served mostly as his daily driver in addition to being a tow rig, parts, and people hauler. However, it was immediately apparent that the lack of torque had become a safety issue while towing. Things were kicked into high gear after the trip, and Greg decided to build a stroker with a cog-drive MagnaCharger for maximum grunt. Having already swapped out the 4L60E transmission for a 4L80E, this would be the ultimate go-anywhere stump puller.

Starting from the bottom, the basis of the new LSx bullet is a 6.0L truck block from Summit Racing. There is no need to scour the junkyard for these blocks anymore; Summit sells them for $750 (PN SUM-150105) fully machined. This Gen III cast-iron workhorse comes painted black with the factory six-bolt mains, cam bearings, freeze plugs, 9.240-inch deck height, 4.030-inch bore, and will accommodate up to a 4.00-inch stroke (a Gen IV version is also available with the side-mounted knock sensors). With boost in mind, we also sourced a forged 4340 rotating assembly from Callies including Compstar H-beam 6.125-inch connecting rods and a 4.00-inch stroke crankshaft. Since the ’03 Avalanche came with a Gen III LSx, we checked the box for the 24x reluctor wheel (PN APO31N-CS24). And, last but not least, Wiseco came through with a killer set of 4.030-inch 2618 alloy forged pistons. The lower silicone content and -18cc dish make them ideal for boost and abuse.

The key to building a reliable combination for boost is adding strength wherever possible, from the rotating assembly and block to even more mundane items like the fasteners and head gaskets. ARP main studs and head studs were essential on this build, and highly recommended on most supercharged LSx motors. Though many have gotten away with less, it isn’t worth the gamble—particularly on the head bolts. Factory blocks use only four bolts per cylinder to seal the heads, which can become prone to lifting under higher boost levels. LS9 head gaskets (PN 12622033) are yet another tried-and-true upgrade to keep the engine sealed under boost. The seven-layer design was obviously conceived with boost in mind, and slightly thicker than the five-layer LS3 gasket. When sandwiched between a set of LS3 cylinder heads (70cc combustion chamber), the 408ci LSx would have a 9.2:1 compression ratio, which is perfectly suitable for pump gas.

A call was placed to COMP Cams to complete the long-block with a stout valvetrain to command the LS3 heads. A custom hydraulic roller camshaft was spec’d with .653/.648-inch lift and 231/244 duration at .050, cut on a 114LSA with 2 degrees of advance. The lobes are from the XE-R and LSL line, combining aggressive ramps on the exhaust and stability on the intake side. Given the positive displacement blower’s nature to provide full boost practically off idle, the cam is designed to manage cylinder pressure and make up for its shortcomings on the top end. An adjustable timing set is always a great idea when using a custom cam, so COMP sent a single roller (PN 3158KT). This piece is plenty strong enough, but should you require a double roller: Be prepared to modify the timing cover or purchase an aftermarket cover. Since we planned to spin the motor quite hard, COMP sent its link-bar lifters (PN 15956-16). These short-travel hydraulic roller lifters limit the internal piston to increase valvetrain efficiency and prevent high rpm failure. A set of stock (7.400-inch) length Hi-Tech pushrods will connect to Ultra Pro Magnum roller rockers, with roller tips, investment-cast 8650 chromoly steel body, and upgraded trunion.

Follow along as AntiVenom shows how to build a reliable boosted LSx combination for a GM truck that will show, go, and tow. On the next installment we’ll drop the blower onto the 408-cube engine, install it in the Avalanche with a high-flowing exhaust system, and strap it to the dyno.

| 2003 Chevrolet Avalanche 5 3l Engine

1. Greg Lovell’s ’03 Chevrolet Avalanche has been hauling hot rods and people with a 5.3L LM7 V-8. This Gen III small-block made 285 hp from the factory and 325 lb-ft of torque. However, AntiVenom had also installed electric fans, cold air intake, ported throttle body, and a COMP 216/220-duration cam to up the ante. On AntiVenom’s Dynojet this equated to around 270 rwhp—not nearly enough for Greg’s needs.

| 6 0 Iron Block

2. One of the coolest things about the LSx series of engines (Gen III/IV) is that most things are interchangeable, including engine blocks. The 6.0L LQ4/LQ9 iron block makes a suitable replacement for the 5.3-liter, adding considerable cubic inches on its own or with a stroker crankshaft. Summit Racing sells the Gen III-style 6.0-liter (PN SUM-150105) fully machined with a 4.030-inch bore and ready to build into a 408ci monster.

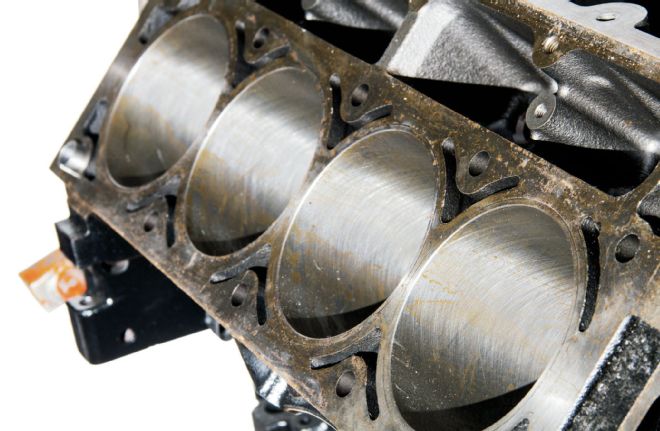

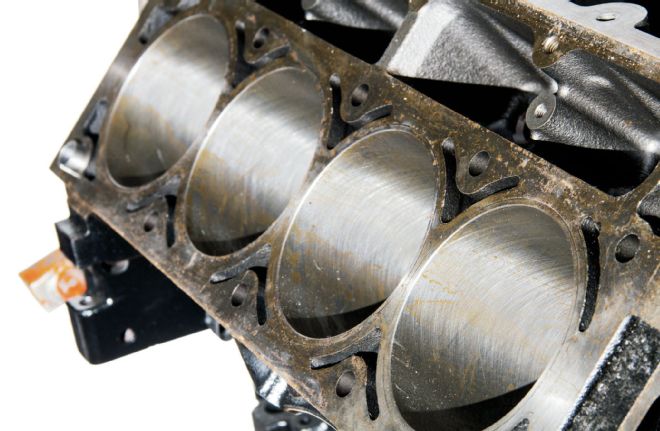

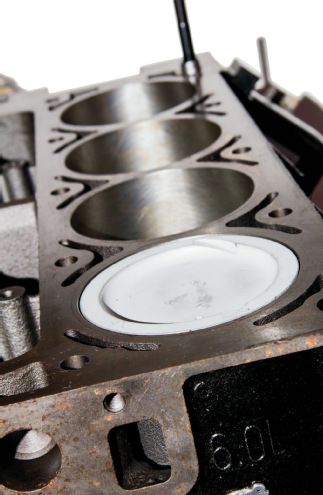

| Crosshatch

3. By the crosshatch you can tell that the GM block comes from Summit Racing honed and ready to go. If you are used to seeing aluminum blocks, you’ll notice that the iron block has different coolant passages and obviously no cylinder sleeves. Much of the internal structure and thickness is identical to the aluminum block, making it extremely strong. The one downfall for high boost is the four-head-bolts per cylinder.

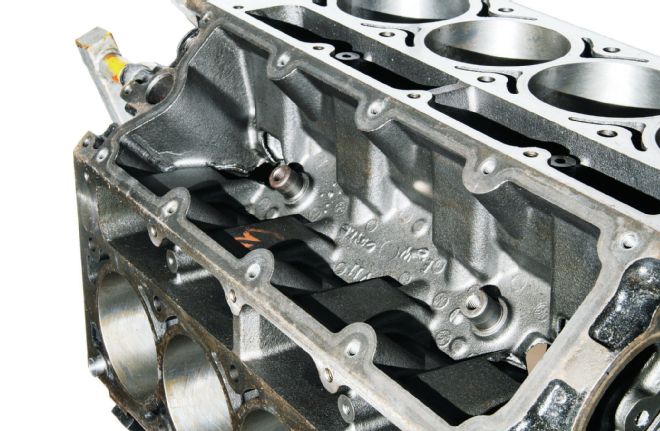

| Cam Bearings

4. The block also comes with cam bearings installed, and a warranty tag (far right) that will indicate whether the block has been overheated (voiding the warranty).

| Knock Sensors

5. Since this is a Gen III block there are provisions for the knock sensors in the valley. Gen IV engines locate the knock sensors on the side of the block. Opinions vary on how effective the knock sensors operate when relocated, but sticking to the proper generation will at least avoid the hassle. On the Avalanche, Gen IVs were introduced on the 2007 model as well as the Silverado/Sierra.

| Arp Main Studs

6. Supercharged combinations are particularly hard on the crank, so ARP main studs (PN 234-5608) are a must. AntiVenom also elected to use bearings from Calico Coatings. The CT-1 Dry Film Lubricant coating reduces friction and wear, particularly on initial start-up.

| 4340 Forged Crankshaft

7. A Callies Compstar 4340 forged crankshaft (PN APO31N-CS24) will provide the thrust in this 408-cube build. Again, since this is a Gen III, Greg went with the 24x reluctor wheel (the Gen IV uses a 58x). The reluctor wheel is where the PCM pulls the crank signal, so this is essential to having a running engine.

| Factory Six Bolt Main Caps

8. Greg slides the factory six-bolt main caps (another awesome feature of LSx engines) onto the studs after treating the bearings with some assembly lube. At the bottom you can get a peak at the rolled fillets on the sturdy Callies crank.

| Camshaft Install

9. Greg uses more assembly lube when installing the camshaft. This piece is a custom grind that combines two different lobe profiles with .653/.648-inch lift and 231/244 duration. Compared to a stock cam, the 114LSA is on the tight side and will bleed off a little boost, but that isn’t a huge concern with a positive displacement blower. The cam is secured with a factory retention plate before installing the timing set.

| Thrust Bearing

10. A screwdriver is used to protect the thrust bearing, which is inserted between the counterweight and the main cap, while getting the lower timing gear seated.

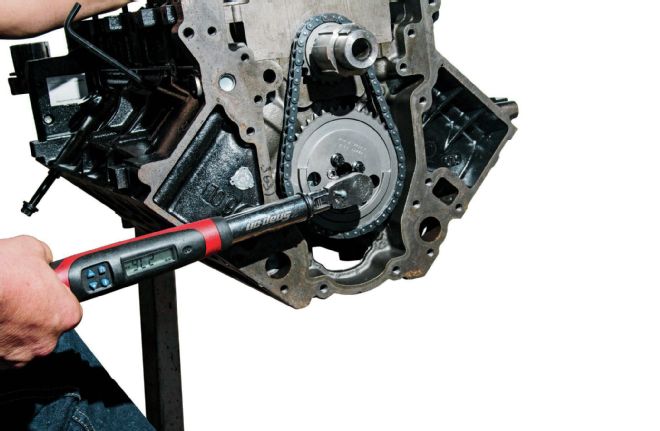

| Electronic Torque Wrench

11. Greg uses an electronic torque wrench to dial in 23 ft-lb on the upper timing gear bolts, which have been treated to red Loctite. Since the cam has two degrees of advance, we elected to use a single hex adjust timing set from COMP Cams (PN 3158KT). This will allow Greg to move the cam back to zero advance if he wants to shift the power curve down. If you are used to Gen I/II small-blocks, a single roller might seem like a bad idea, but they hold up quite well on LSx engines and fit perfectly. Double rollers require modifying the factory timing cover for clearance or an aftermarket unit.

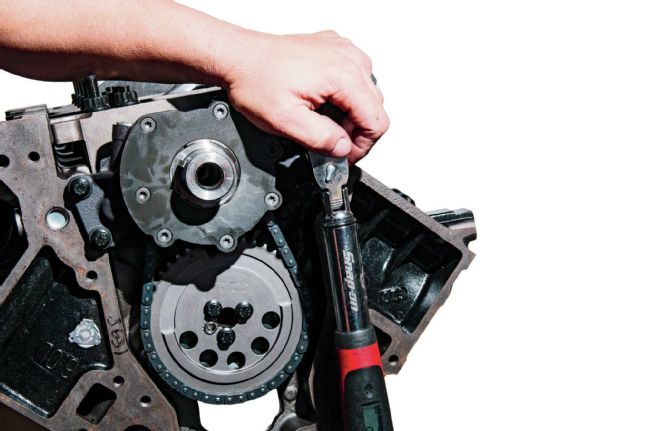

| Melling High Volume Oil Pump

12. Greg elected to use a Melling high-volume oil pump to increase the volume and pressure of the wet-sump system. At $160, it’s cheap insurance for keeping your LSx motor together.

| Torqued Down Studs

13. Before dropping the pistons and rods in, the main studs were torqued down using 60 ft-lb on the inside, 50 ft-lb on the outside, and 22 ft-lb on the side (skirt).

| Wiseco Pistons

14. Forged Wiseco pistons with Total Seal rings and Callies Compstar rods were assembled prior to our arrival. Between the power and the abuse this truck will see on the street, 4340 H-beam rods and 2618 alloy pistons were needed. Greg had the pistons coated locally with a high-temp coating on the dome and an oil-shedding coating on the underside to match the skirt coating. Since these pistons won’t have the benefit of oil squirters like a factory LS9 or LSA, they need all the help they can get.

| Ring Compressor

15. Once Greg got the piston/rod assembly into place he broke out the ring compressor before tapping the pistons into the cylinder and guiding the rod ends around the crank journal. Piston skirt design is particularly critical on LSx engines given the relatively short cylinder sleeve on many of the blocks including the 6.0-liter. As the pistons pop out of the hole they become unstable and can scuff the cylinder.

| Ap 2000 Rod Bolts

16. After flipping the engine over on the stand, Greg torques down the ARP 2000 rod bolts with 26 ft-lb using the supplied ARP moly lube.

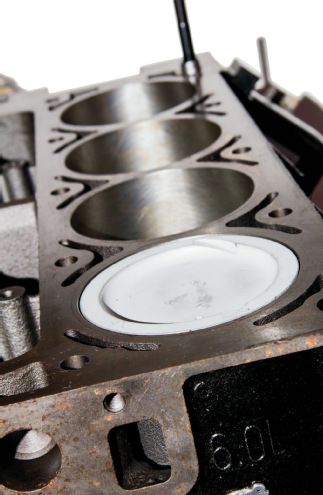

| 18cc Dish

17. Here is a better look at the -18cc dish on the coated Wiseco pistons, now installed and nearly flush to the block surface. Summit resurfaces the block prior to shipping (zero deck).

| Comp Cams Link Bar

18. Given the abuse this engine will see, COMP Cam’s link-bar lifters (PN 15956-16) were the chosen apparatus for enacting the cam’s commands. These things will spin well past 7,000 rpm, and are a great compromise between a hydraulic and solid roller. The factory plastic lifter trays are no longer used with these, and you never have to worry about dropping a lifter into the oil pan when changing the cam.

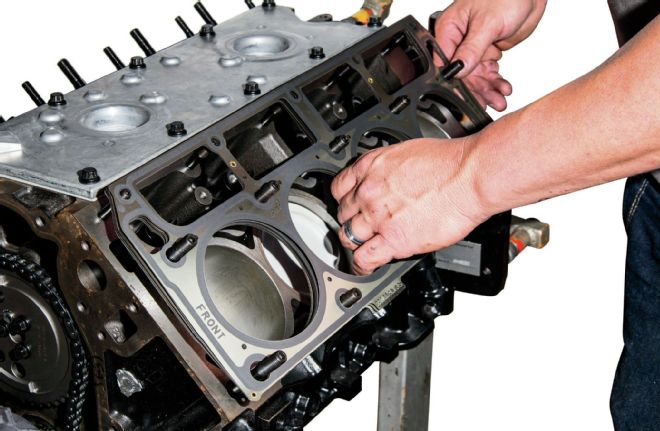

| Ls9 Head Gaskets

19. Greg installed the valley cover before dropping on a set of LS9 head gaskets (PN 12622033). These are the go-to head gasket for boost on an LSx engine with a 4.00-4.070 bore (actual gasket has a 4.100-inch bore). With a compressed thickness of .055-inch, seven layers of stainless steel will keep the heads sealed under high cylinder pressure.

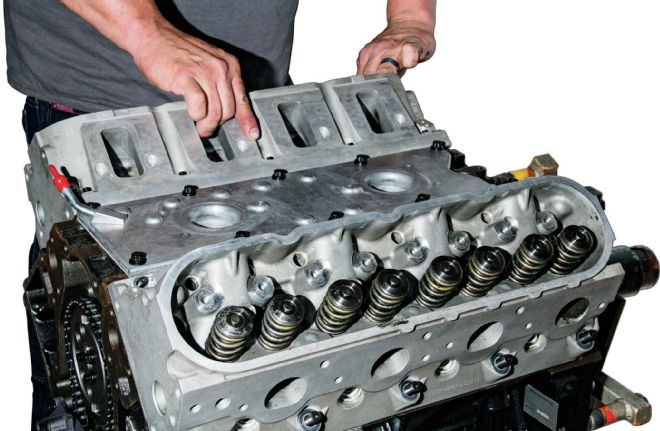

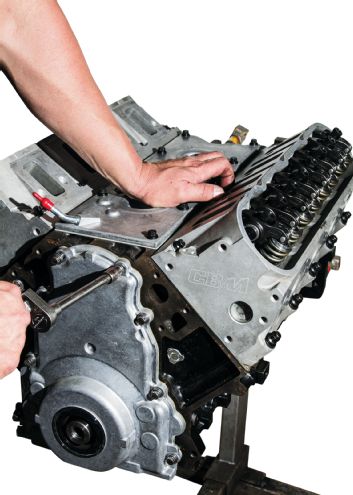

| Gen Three Cylinder Heads

20. Greg decided to ditch the LM7’s cathedral-style Gen III cylinder heads and switch to a Gen IV rectangular port. These CBM-ported LS3 cylinder heads seemed the ideal way to top off the motor. As cast, these heads flow over 300 cfm, which is already more than enough. With the CNC-porting it should push the heads closer to 330 cfm. As you can see, COMP dual valvesprings came with the heads, along with stock hollow-stem intake and exhaust valves.

| High Lift Cam

21. Even with the high-lift cam and short-travel lifters, stock-length (7.400-inch) pushrods are still sufficient. Among the lifters, heavy springs, and boost, stock pushrods are not recommended. These are from COMP Cams.

| Lsx Rocker Arms

22. Whenever you are building an LSx engine and using an aftermarket cam and valvesprings you should upgrade the rocker arms. At the very least you will need a trunion upgrade to keep the stock needle bearings from exiting and ruining your brand-new motor. However, if you are going from cathedral- to rectangular-port heads you will also need offset intake rockers and new stands. Or you could upgrade to these COMP Cams Ultra Pro Magnum Roller Rockers (PN 16765-KIT) and make life simple. The 1.8 ratio adds lift and the chromoly body is much stiffer than stock. They even come with pushrod guideplates.

| Timing Cover Tool

23. For proper alignment, Greg uses a timing cover installation tool. Since we are using a single roller timing chain, a factory timing cover is sufficient. It is also important to note that Gen IV engines use an entirely different timing cover that encompasses the cam sensor and other goodies depending on the engine.

| Arp Head Studs

24. Last but not least, Greg torques the ARP head studs (PN 234-4317) initially with 25-30 ft-lb before making a final pass at 90 ft-lb (using the provided lube). Greg noted the design on these studs was recently changed, enlarging the head and negating the washers. Rated at 200,000 psi, these heat-treated 8740 fasteners should be sufficient for the intended 16 psi from a TVS2300 supercharger. Don’t miss the next installment when we drop the blower onto this beast, into the truck, and make some pulls.

| 2003 Chevrolet Avalanche 5 3l Engine

1. Greg Lovell’s ’03 Chevrolet Avalanche has been hauling hot rods and people with a 5.3L LM7 V-8. This Gen III small-block made 285 hp from the factory and 325 lb-ft of torque. However, AntiVenom had also installed electric fans, cold air intake, ported throttle body, and a COMP 216/220-duration cam to up the ante. On AntiVenom’s Dynojet this equated to around 270 rwhp—not nearly enough for Greg’s needs.

| 2003 Chevrolet Avalanche 5 3l Engine

1. Greg Lovell’s ’03 Chevrolet Avalanche has been hauling hot rods and people with a 5.3L LM7 V-8. This Gen III small-block made 285 hp from the factory and 325 lb-ft of torque. However, AntiVenom had also installed electric fans, cold air intake, ported throttle body, and a COMP 216/220-duration cam to up the ante. On AntiVenom’s Dynojet this equated to around 270 rwhp—not nearly enough for Greg’s needs.

| 6 0 Iron Block

2. One of the coolest things about the LSx series of engines (Gen III/IV) is that most things are interchangeable, including engine blocks. The 6.0L LQ4/LQ9 iron block makes a suitable replacement for the 5.3-liter, adding considerable cubic inches on its own or with a stroker crankshaft. Summit Racing sells the Gen III-style 6.0-liter (PN SUM-150105) fully machined with a 4.030-inch bore and ready to build into a 408ci monster.

| 6 0 Iron Block

2. One of the coolest things about the LSx series of engines (Gen III/IV) is that most things are interchangeable, including engine blocks. The 6.0L LQ4/LQ9 iron block makes a suitable replacement for the 5.3-liter, adding considerable cubic inches on its own or with a stroker crankshaft. Summit Racing sells the Gen III-style 6.0-liter (PN SUM-150105) fully machined with a 4.030-inch bore and ready to build into a 408ci monster.

| Crosshatch

3. By the crosshatch you can tell that the GM block comes from Summit Racing honed and ready to go. If you are used to seeing aluminum blocks, you’ll notice that the iron block has different coolant passages and obviously no cylinder sleeves. Much of the internal structure and thickness is identical to the aluminum block, making it extremely strong. The one downfall for high boost is the four-head-bolts per cylinder.

| Crosshatch

3. By the crosshatch you can tell that the GM block comes from Summit Racing honed and ready to go. If you are used to seeing aluminum blocks, you’ll notice that the iron block has different coolant passages and obviously no cylinder sleeves. Much of the internal structure and thickness is identical to the aluminum block, making it extremely strong. The one downfall for high boost is the four-head-bolts per cylinder.

| Cam Bearings

4. The block also comes with cam bearings installed, and a warranty tag (far right) that will indicate whether the block has been overheated (voiding the warranty).

| Cam Bearings

4. The block also comes with cam bearings installed, and a warranty tag (far right) that will indicate whether the block has been overheated (voiding the warranty).

| Knock Sensors

5. Since this is a Gen III block there are provisions for the knock sensors in the valley. Gen IV engines locate the knock sensors on the side of the block. Opinions vary on how effective the knock sensors operate when relocated, but sticking to the proper generation will at least avoid the hassle. On the Avalanche, Gen IVs were introduced on the 2007 model as well as the Silverado/Sierra.

| Knock Sensors

5. Since this is a Gen III block there are provisions for the knock sensors in the valley. Gen IV engines locate the knock sensors on the side of the block. Opinions vary on how effective the knock sensors operate when relocated, but sticking to the proper generation will at least avoid the hassle. On the Avalanche, Gen IVs were introduced on the 2007 model as well as the Silverado/Sierra.

| Arp Main Studs

6. Supercharged combinations are particularly hard on the crank, so ARP main studs (PN 234-5608) are a must. AntiVenom also elected to use bearings from Calico Coatings. The CT-1 Dry Film Lubricant coating reduces friction and wear, particularly on initial start-up.

| Arp Main Studs

6. Supercharged combinations are particularly hard on the crank, so ARP main studs (PN 234-5608) are a must. AntiVenom also elected to use bearings from Calico Coatings. The CT-1 Dry Film Lubricant coating reduces friction and wear, particularly on initial start-up.

| 4340 Forged Crankshaft

7. A Callies Compstar 4340 forged crankshaft (PN APO31N-CS24) will provide the thrust in this 408-cube build. Again, since this is a Gen III, Greg went with the 24x reluctor wheel (the Gen IV uses a 58x). The reluctor wheel is where the PCM pulls the crank signal, so this is essential to having a running engine.

| 4340 Forged Crankshaft

7. A Callies Compstar 4340 forged crankshaft (PN APO31N-CS24) will provide the thrust in this 408-cube build. Again, since this is a Gen III, Greg went with the 24x reluctor wheel (the Gen IV uses a 58x). The reluctor wheel is where the PCM pulls the crank signal, so this is essential to having a running engine.

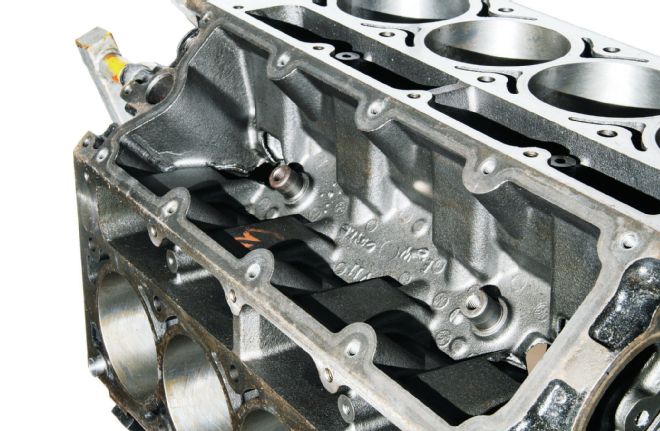

| Factory Six Bolt Main Caps

8. Greg slides the factory six-bolt main caps (another awesome feature of LSx engines) onto the studs after treating the bearings with some assembly lube. At the bottom you can get a peak at the rolled fillets on the sturdy Callies crank.

| Factory Six Bolt Main Caps

8. Greg slides the factory six-bolt main caps (another awesome feature of LSx engines) onto the studs after treating the bearings with some assembly lube. At the bottom you can get a peak at the rolled fillets on the sturdy Callies crank.

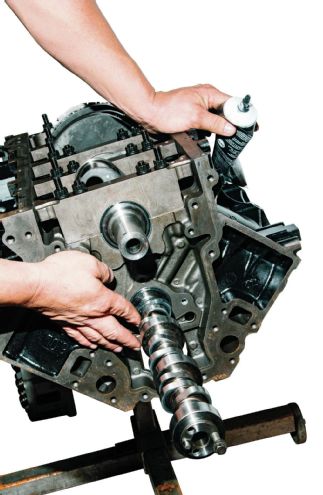

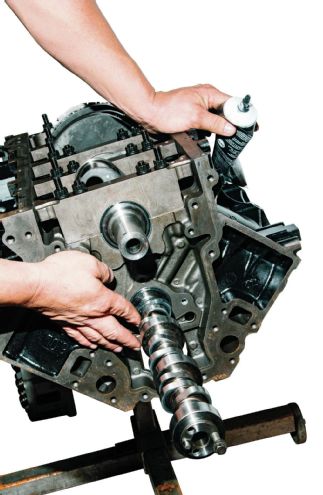

| Camshaft Install

9. Greg uses more assembly lube when installing the camshaft. This piece is a custom grind that combines two different lobe profiles with .653/.648-inch lift and 231/244 duration. Compared to a stock cam, the 114LSA is on the tight side and will bleed off a little boost, but that isn’t a huge concern with a positive displacement blower. The cam is secured with a factory retention plate before installing the timing set.

| Camshaft Install

9. Greg uses more assembly lube when installing the camshaft. This piece is a custom grind that combines two different lobe profiles with .653/.648-inch lift and 231/244 duration. Compared to a stock cam, the 114LSA is on the tight side and will bleed off a little boost, but that isn’t a huge concern with a positive displacement blower. The cam is secured with a factory retention plate before installing the timing set.

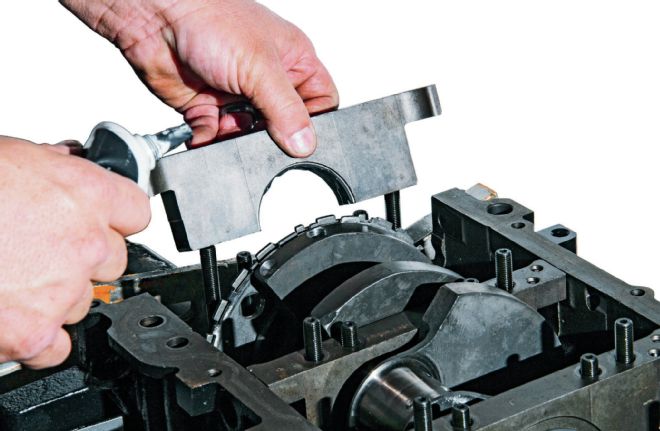

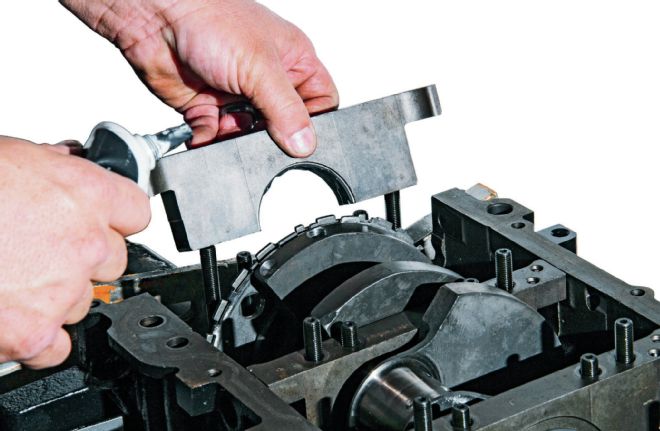

| Thrust Bearing

10. A screwdriver is used to protect the thrust bearing, which is inserted between the counterweight and the main cap, while getting the lower timing gear seated.

| Thrust Bearing

10. A screwdriver is used to protect the thrust bearing, which is inserted between the counterweight and the main cap, while getting the lower timing gear seated.

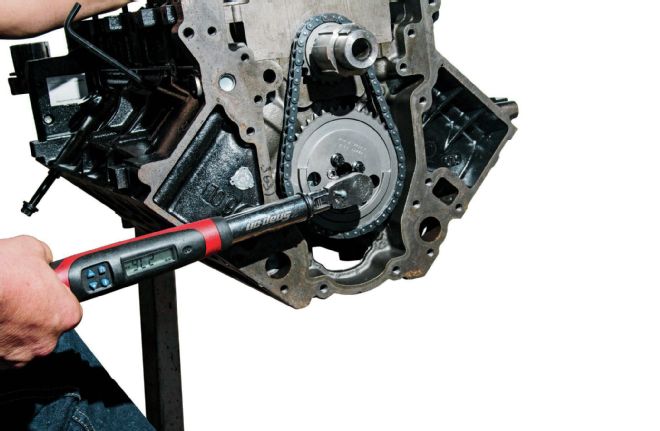

| Electronic Torque Wrench

11. Greg uses an electronic torque wrench to dial in 23 ft-lb on the upper timing gear bolts, which have been treated to red Loctite. Since the cam has two degrees of advance, we elected to use a single hex adjust timing set from COMP Cams (PN 3158KT). This will allow Greg to move the cam back to zero advance if he wants to shift the power curve down. If you are used to Gen I/II small-blocks, a single roller might seem like a bad idea, but they hold up quite well on LSx engines and fit perfectly. Double rollers require modifying the factory timing cover for clearance or an aftermarket unit.

| Electronic Torque Wrench

11. Greg uses an electronic torque wrench to dial in 23 ft-lb on the upper timing gear bolts, which have been treated to red Loctite. Since the cam has two degrees of advance, we elected to use a single hex adjust timing set from COMP Cams (PN 3158KT). This will allow Greg to move the cam back to zero advance if he wants to shift the power curve down. If you are used to Gen I/II small-blocks, a single roller might seem like a bad idea, but they hold up quite well on LSx engines and fit perfectly. Double rollers require modifying the factory timing cover for clearance or an aftermarket unit.

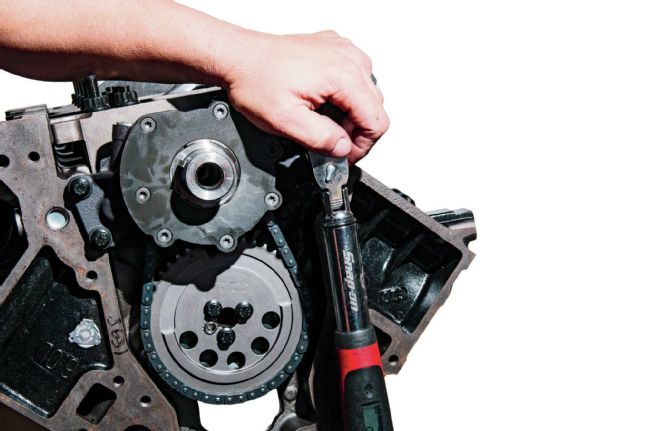

| Melling High Volume Oil Pump

12. Greg elected to use a Melling high-volume oil pump to increase the volume and pressure of the wet-sump system. At $160, it’s cheap insurance for keeping your LSx motor together.

| Melling High Volume Oil Pump

12. Greg elected to use a Melling high-volume oil pump to increase the volume and pressure of the wet-sump system. At $160, it’s cheap insurance for keeping your LSx motor together.

| Torqued Down Studs

13. Before dropping the pistons and rods in, the main studs were torqued down using 60 ft-lb on the inside, 50 ft-lb on the outside, and 22 ft-lb on the side (skirt).

| Torqued Down Studs

13. Before dropping the pistons and rods in, the main studs were torqued down using 60 ft-lb on the inside, 50 ft-lb on the outside, and 22 ft-lb on the side (skirt).

| Wiseco Pistons

14. Forged Wiseco pistons with Total Seal rings and Callies Compstar rods were assembled prior to our arrival. Between the power and the abuse this truck will see on the street, 4340 H-beam rods and 2618 alloy pistons were needed. Greg had the pistons coated locally with a high-temp coating on the dome and an oil-shedding coating on the underside to match the skirt coating. Since these pistons won’t have the benefit of oil squirters like a factory LS9 or LSA, they need all the help they can get.

| Wiseco Pistons

14. Forged Wiseco pistons with Total Seal rings and Callies Compstar rods were assembled prior to our arrival. Between the power and the abuse this truck will see on the street, 4340 H-beam rods and 2618 alloy pistons were needed. Greg had the pistons coated locally with a high-temp coating on the dome and an oil-shedding coating on the underside to match the skirt coating. Since these pistons won’t have the benefit of oil squirters like a factory LS9 or LSA, they need all the help they can get.

| Ring Compressor

15. Once Greg got the piston/rod assembly into place he broke out the ring compressor before tapping the pistons into the cylinder and guiding the rod ends around the crank journal. Piston skirt design is particularly critical on LSx engines given the relatively short cylinder sleeve on many of the blocks including the 6.0-liter. As the pistons pop out of the hole they become unstable and can scuff the cylinder.

| Ring Compressor

15. Once Greg got the piston/rod assembly into place he broke out the ring compressor before tapping the pistons into the cylinder and guiding the rod ends around the crank journal. Piston skirt design is particularly critical on LSx engines given the relatively short cylinder sleeve on many of the blocks including the 6.0-liter. As the pistons pop out of the hole they become unstable and can scuff the cylinder.

| Ap 2000 Rod Bolts

16. After flipping the engine over on the stand, Greg torques down the ARP 2000 rod bolts with 26 ft-lb using the supplied ARP moly lube.

| Ap 2000 Rod Bolts

16. After flipping the engine over on the stand, Greg torques down the ARP 2000 rod bolts with 26 ft-lb using the supplied ARP moly lube.

| 18cc Dish

17. Here is a better look at the -18cc dish on the coated Wiseco pistons, now installed and nearly flush to the block surface. Summit resurfaces the block prior to shipping (zero deck).

| 18cc Dish

17. Here is a better look at the -18cc dish on the coated Wiseco pistons, now installed and nearly flush to the block surface. Summit resurfaces the block prior to shipping (zero deck).

| Comp Cams Link Bar

18. Given the abuse this engine will see, COMP Cam’s link-bar lifters (PN 15956-16) were the chosen apparatus for enacting the cam’s commands. These things will spin well past 7,000 rpm, and are a great compromise between a hydraulic and solid roller. The factory plastic lifter trays are no longer used with these, and you never have to worry about dropping a lifter into the oil pan when changing the cam.

| Comp Cams Link Bar

18. Given the abuse this engine will see, COMP Cam’s link-bar lifters (PN 15956-16) were the chosen apparatus for enacting the cam’s commands. These things will spin well past 7,000 rpm, and are a great compromise between a hydraulic and solid roller. The factory plastic lifter trays are no longer used with these, and you never have to worry about dropping a lifter into the oil pan when changing the cam.

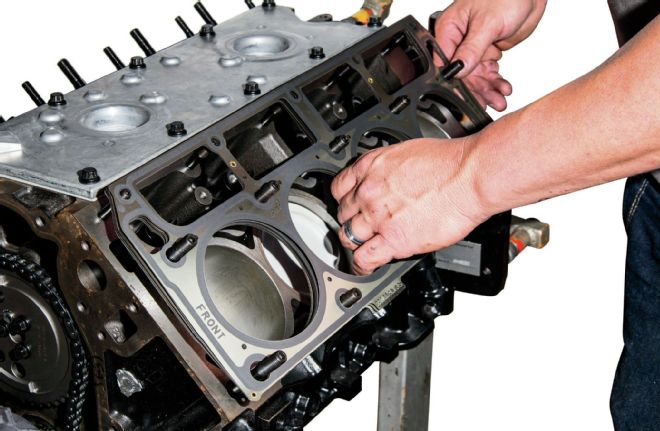

| Ls9 Head Gaskets

19. Greg installed the valley cover before dropping on a set of LS9 head gaskets (PN 12622033). These are the go-to head gasket for boost on an LSx engine with a 4.00-4.070 bore (actual gasket has a 4.100-inch bore). With a compressed thickness of .055-inch, seven layers of stainless steel will keep the heads sealed under high cylinder pressure.

| Ls9 Head Gaskets

19. Greg installed the valley cover before dropping on a set of LS9 head gaskets (PN 12622033). These are the go-to head gasket for boost on an LSx engine with a 4.00-4.070 bore (actual gasket has a 4.100-inch bore). With a compressed thickness of .055-inch, seven layers of stainless steel will keep the heads sealed under high cylinder pressure.

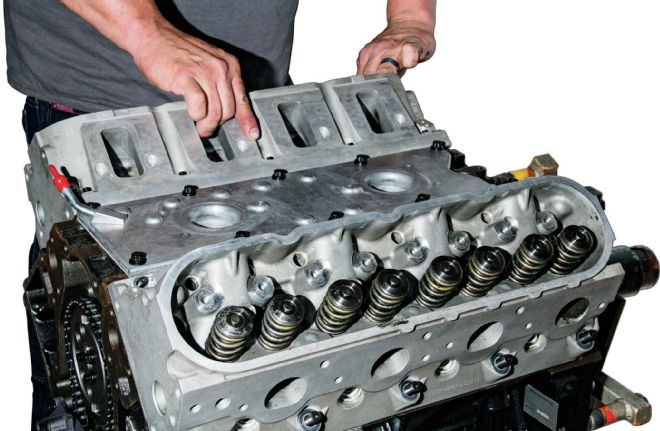

| Gen Three Cylinder Heads

20. Greg decided to ditch the LM7’s cathedral-style Gen III cylinder heads and switch to a Gen IV rectangular port. These CBM-ported LS3 cylinder heads seemed the ideal way to top off the motor. As cast, these heads flow over 300 cfm, which is already more than enough. With the CNC-porting it should push the heads closer to 330 cfm. As you can see, COMP dual valvesprings came with the heads, along with stock hollow-stem intake and exhaust valves.

| Gen Three Cylinder Heads

20. Greg decided to ditch the LM7’s cathedral-style Gen III cylinder heads and switch to a Gen IV rectangular port. These CBM-ported LS3 cylinder heads seemed the ideal way to top off the motor. As cast, these heads flow over 300 cfm, which is already more than enough. With the CNC-porting it should push the heads closer to 330 cfm. As you can see, COMP dual valvesprings came with the heads, along with stock hollow-stem intake and exhaust valves.

| High Lift Cam

21. Even with the high-lift cam and short-travel lifters, stock-length (7.400-inch) pushrods are still sufficient. Among the lifters, heavy springs, and boost, stock pushrods are not recommended. These are from COMP Cams.

| High Lift Cam

21. Even with the high-lift cam and short-travel lifters, stock-length (7.400-inch) pushrods are still sufficient. Among the lifters, heavy springs, and boost, stock pushrods are not recommended. These are from COMP Cams.

| Lsx Rocker Arms

22. Whenever you are building an LSx engine and using an aftermarket cam and valvesprings you should upgrade the rocker arms. At the very least you will need a trunion upgrade to keep the stock needle bearings from exiting and ruining your brand-new motor. However, if you are going from cathedral- to rectangular-port heads you will also need offset intake rockers and new stands. Or you could upgrade to these COMP Cams Ultra Pro Magnum Roller Rockers (PN 16765-KIT) and make life simple. The 1.8 ratio adds lift and the chromoly body is much stiffer than stock. They even come with pushrod guideplates.

| Lsx Rocker Arms

22. Whenever you are building an LSx engine and using an aftermarket cam and valvesprings you should upgrade the rocker arms. At the very least you will need a trunion upgrade to keep the stock needle bearings from exiting and ruining your brand-new motor. However, if you are going from cathedral- to rectangular-port heads you will also need offset intake rockers and new stands. Or you could upgrade to these COMP Cams Ultra Pro Magnum Roller Rockers (PN 16765-KIT) and make life simple. The 1.8 ratio adds lift and the chromoly body is much stiffer than stock. They even come with pushrod guideplates.

| Timing Cover Tool

23. For proper alignment, Greg uses a timing cover installation tool. Since we are using a single roller timing chain, a factory timing cover is sufficient. It is also important to note that Gen IV engines use an entirely different timing cover that encompasses the cam sensor and other goodies depending on the engine.

| Timing Cover Tool

23. For proper alignment, Greg uses a timing cover installation tool. Since we are using a single roller timing chain, a factory timing cover is sufficient. It is also important to note that Gen IV engines use an entirely different timing cover that encompasses the cam sensor and other goodies depending on the engine.

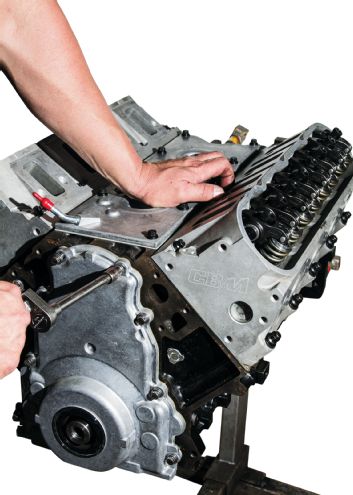

| Arp Head Studs

24. Last but not least, Greg torques the ARP head studs (PN 234-4317) initially with 25-30 ft-lb before making a final pass at 90 ft-lb (using the provided lube). Greg noted the design on these studs was recently changed, enlarging the head and negating the washers. Rated at 200,000 psi, these heat-treated 8740 fasteners should be sufficient for the intended 16 psi from a TVS2300 supercharger. Don’t miss the next installment when we drop the blower onto this beast, into the truck, and make some pulls.

| Arp Head Studs

24. Last but not least, Greg torques the ARP head studs (PN 234-4317) initially with 25-30 ft-lb before making a final pass at 90 ft-lb (using the provided lube). Greg noted the design on these studs was recently changed, enlarging the head and negating the washers. Rated at 200,000 psi, these heat-treated 8740 fasteners should be sufficient for the intended 16 psi from a TVS2300 supercharger. Don’t miss the next installment when we drop the blower onto this beast, into the truck, and make some pulls.