| biodiesel Engine Safety biodiesel Pump

Biodiesel is getting a lot of attention these days. Many folks are enamored by the fact that it's not made of dead dinosaurs found under countries with unfriendly leaders, but that doesn't automatically mean it's safe to put in your Cummins, Duramax, or Power Stroke engine. General Electric (makers of everything from light bulbs to Late Night with Conan O'Brien to fuel additives) has put together one of the most comprehensive studies of pure 100 percent biodiesel (B100) and its effects on the modern turbodiesel engines we all love. Here are GE's conclusions based on numerous tests that can't be performed by your local bio-fuel co-op.-The Diesel Power staff

Although biodiesel is not a new fuel, commercialization is increasing as regulations promote the use of green fuels in the marketplace. Fuel system failures and operability problems have been encountered as biodiesel use becomes more widespread. Stability issues include understanding the mechanism of degradation of biodiesel and interactions in petroleum-based fuels, determination of stability that predicts operability, and measurement of the degradation. These issues are reviewed and preventative measures are identified for the mechanisms that may contribute to biodiesel instability. Case studies are included to demonstrate how fuel additives are successfully being used to prevent the operability problems in biodiesel fuel blends.

Managing The Stability Of B100 And Biodiesel Blends Blends of biodiesel are now well-adopted fuels that are gaining market share and popularity. Biodiesel is a fuel comprised of mono-alkyl esters of long chain fatty acids derived from vegetable oils or animal fats and meeting the requirements of ASTM D-6751 (a standard set by the American Society for Testing and Materials). However, several unique characteristics of biodiesel, also known as fatty acid methyl esters (FAME) or B100, may cause some operability problems. Low-temperature fluidity, water haze, and thermal and oxidation stability are the most significant issues facing the marketers and end users of biodiesel.

Cold Flow Improver technology is evolving, but, because of the composition of B100 and especially soy oil esters, the improvement using additives is limited to a few degrees Fahrenheit. Understanding the chemical makeup of biodiesel and the measurement of the metrics that could impact operability are key to understanding the root causes of instability and are helpful in formulating solutions to overcome stability problems. The work by J. Andrews Waynick of Southwest Research Institute(13) appears to be the most comprehensive and inclusive document on this subject. Now that fuels containing B100 are being used, experiential information and data can be introduced into the analyses of these critical areas.

The variables that have been identified include glycerol content, free fatty acid content, metals, and carbon-carbon double bond types and configurations (degree and level of unsaturation). The manufacturing process is a significant potential source of stability problems, and process controls are the first line of defense to achieve and maintain biodiesel stability. Fuel-blending strategies and fuel additives are now gaining interest to meet market demands for viable fuels containing biodiesel. Fuel additives are successfully being used to improve operability by preventing oxidation and thermal degradation of biodiesel and blends of biodiesel. For clarification, B100 is used in reference to methyl esters and biodiesel blend is used in reference to blends containing petroleum distillate fuels and B100.

The Manufacturing Process, A Critical Success Factor B100 is produced in a batch process by transesterification of methanol with triglycerides, also known as glycerol fatty acids, in the presence of caustic materials. The degree of completion of the reaction to replace the glycerol with an alcohol such as methanol was recognized as important to fuel quality early in the development of biodiesel. The reaction is conducted at elevated temperatures of around 120-150 degrees Fahrenheit to drive the reaction to completion. The mixture is then neutralized with an acid and washed to remove excess methanol, salts, and free glycerol. Effective neutralization is required to remove alkali metals from the oil phase. If washing is not effective, the salts and glycerol may remain in the B100. Minimizing glycerol levels is required to ensure quality B100 production. Maximizing the degree of completion of the esterification reaction minimizes free fatty acids that can contribute to instability. Removal of alkali metal salts from the process and drying is also important to meet the quality standard of a finished B100 product. Process controls and quality testing are required to achieve the quality standards established in ASTM D-6751. These standards are currently being reviewed based on recent problems with biodiesel blends in the marketplace, and modifications may be recommended to prevent potential operability problems in the future with biodiesel products.

| Figure 1: Relationship between B100 and stability(7).

Why is stability important?Oxidation and polymerization reactions have been recognized throughout the refining and automotive industries as causes of filter pluggage, fuel injector and pump deposits, injector coking, and corrosion(4). Oxidation byproducts, such as acids and carbonyls, cause corrosion and accelerate the degradation process. Degradation byproducts may be insoluble in the diesel blends and cause filter plugging in fuel systems.

Fuel-filter pluggage and engine-deposit formation may be related to total insolubles formation, but neat B100 does not give significant insolubles when tested by storage stability tests(6). This may be due to the solubility of the polar degradation byproducts in the somewhat polar B100, but these byproducts can then become insoluble when the biodiesel is blended into the non-polar diesel fuels. Insolubles are expected to become a more significant problem as ULSD, which is more non-polar, is introduced in the marketplace. Truckers are complaining that clogging of engine fuel filters are increasing as animal fat- and soybean-based fuels are being introduced nationwide(14). Fuel system problems, including filter plugging, have been documented in the USA. and fuel-filter pluggage has become an increasing problem in vehicles that use B100 or biodiesel blends. According to a survey conducted by MTA, of 90 fleets, 62 percent said they had experienced fuel-filter plugging(10).

Operability problems increase maintenance costs and decrease equipment reliability, and problems related to biodiesel use could prevent the growth and adoption of biodiesel in the fuel marketplace. Preventing operability problems improves the viability of biodiesel as a fuel.

Measuring Stability The stability of biodiesel can be measured using several different analytical procedures. A commonly cited problem in the literature is that biodiesel stability may be controlled by several mechanisms, and no single analytical test is capable of predicting actual performance in engine systems.

| Effect Of Stability On ViscosityFigure 2: Relationship between B100 stability and viscosity(3).

The OSI Rancimat has been identified as a procedure to measure stability by quantifying the acids formed during the degradation process when biodiesel is exposed to elevated temperatures and oxygen. It has been used to predict the oxidation stability of biodiesel(7). The references to the data shown in Figure 1 indicated that little correlation exists between stability and insolubles. This conclusion is true for linear correlations. However, the correlation coefficient is higher when using an exponential decay relationship, although the correlation is still weak. This may be due to the data scatter in the top left quadrant that could be caused by variation in significant factors such as metals, glycerol content, unstaurates, polyunsaturates, and acids.

Tests such as the ASTM-525 and ASTM-6418 measure the thermal stability of biodiesel by quantifying the color degradation and gum formation. However, many failures in fuel systems where biodiesel used stability measurements could not predict the formation of solids that cause filter plugging, one of the more common problems with biodiesel.

Long-term storage tests, such as ASTM D-4625, have been used to determine oxidation stability. Using this test, biodiesels have been found to be susceptible to oxidation and sunlight can accelerate the process, although light should not be a problem in the fuel applications(3). The effects of aging in long-term storage tests can be measured by changes in viscosity as shown in Figure 2. The correlation for the equation is relatively high, indicating that the relationship can be predicted based on the available data.

Iodine value (IV) can be used to quantify the number of double bonds, a major cause of instability. However, the position and number of double bonds per molecule are important factors in the stability of B100, and the IV cannot distinguish these parameters. The esterification efficiency and free acids, glycerols, and partially transesterified oils are also important variables that cannot be quantified using the IV, so the IV would not be expected to be a good predictor of stability. The composition and molecular structures the oil feedstocks that are used to make B100 have been clearly identified, and, therefore, IV testing would be useful primarily for determining changes in the base oils from degradation.

The results of aging can be measured by IV, total acid number (TAN), anisidine value (aldehydes), and viscosity(6). Acid number increases as B100 ages; this is the evidence of degradation and not a measure of stability(4). These metrics can only quantify the degree of degradation, but do not predict the stability of B100 or biodiesel blends. As shown in Figure 2 (page 84), the viscosity increases in relation to the stability of B100; this is caused by polymerization reactions that occur in the degradation of B100.

Glycerols Glycerols have been identified as a potential cause of biodiesel instability. Glycerol is produced via transesterification of triglycerides with methanol. The measurement of free and total glycerols indicates the removal effectiveness and conversion of the triglycerides to methyl esters. Reaction conditions could result in the formation of oxidized byproducts that cause discoloration, especially when glycerol is exposed to either high temperature or alkaline pH. Glycerol can oxidize or thermally degrade to form diols or acids that can contribute to biodiesel instability. These degradation byproducts may catalyze polymerization of unsaturated fatty acids. The unreacted triglycerides may be oxidized or dissociate over time, resulting in the formation of free glycerol that could polymerize or oxidize; long-term storage can result in exposure to oxygen or metals that facilitate the oxidation process and dissociation of the glycerol to form free fatty acids. These molecules tend to polymerize, forming gums that can foul injection systems and prevent proper fuel atomization or distribution. These gums or insolubles may also plug fuel filters. Free glycerol and oxidized glycerol byproducts may form sediments or cause corrosion(4).

According to John Hausladen, the excess glycerol in biodiesel, when it gets cold, suspends and never goes back into the liquid, contributing to the fuel-filter clogging problems(10). Glycerol resulting from partially reacted or unreacted oils is measured as total and free glycerol; the glycerol specification in ASTMD-6751 was established to maintain a minimum standard for B100 and prevent the detrimental effects of glycerol in biodiesel. B100 should meet the required specifications of either ASTMD-6751 or appropriate European specifications(8). Not meeting these specifications can cause elevated levels of glycerol or soap that could result in insolubles or deposit formation in the fuels and, subsequently, engine operability problems. The most valuable control measure for glycerol is the manufacturing process. Certification of quality that includes the glycerol content and esterification can be required to ensure that the purchased lot of B100 meets the minimum quality standards.

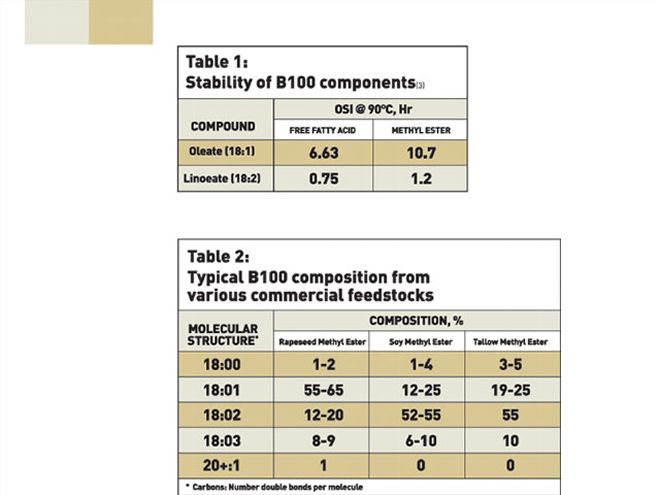

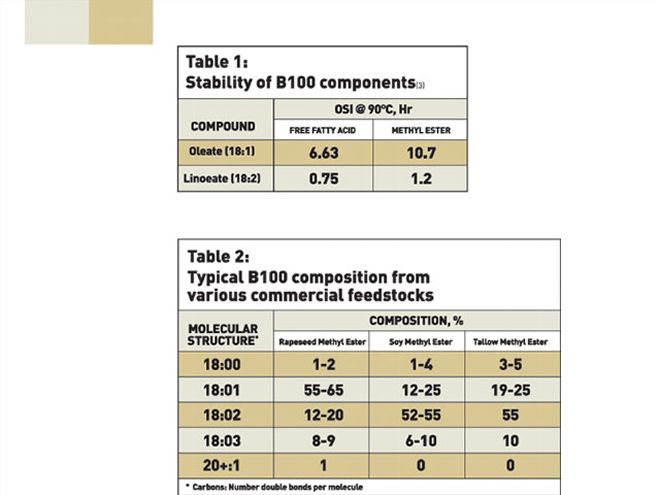

Free Fatty AcidsAcids are a known cause of instability in vegetable oils and hydrocarbon fuels. These may be present in B100 if the transesterification reaction was incomplete and the alkali metal salt of the fatty acid was present in the neutralization and wash process. The alkali metals are removed by acid and the free fatty acid is formed; free fatty acids may degrade or cause corrosion and thermal instability. Free fatty acids can adversely impact the oxidation stability as shown in Table 1. They can undergo oxidation and break down into aldehydes, ketones, epoxides and alcohols(2). Oxidation stability decreases with decreasing molecular weight and with increasing amount of double bonds present and number of double bonds per molecule(1). These reaction byproducts may be of lower molecular weight than the fatty acid; they will likely retain the double bonds, and, because the reaction byproducts have a lower molecular weight, they are more susceptible to polymerization processes. These acids and degradation byproducts then could act as a chain initiator for polymerization of organic compounds, especially unsaturated compounds that contain multiple carbon bonds, and are more susceptible to polymerization. Finally, alkali metal soaps of fatty acids can catalyze instability as well as increase insolubles or water haze.

Driving the transesterification reaction to completion can minimize free acid or partial esterification that leads to free fatty acid catalyzed instability. However, when the possibility of free fatty acids exist, neutralizers can be added to B100 or biodiesel blends to minimize free acid levels and, subsequently, the impacts of free acids on degradation. Antioxidants can be used to prevent, inhibit, or terminate the polymerization mechanisms such as hyperperoxide reaction or diene condensations. The synthetic antioxidants appear to be more effective than naturally occurring antioxidants, which may be removed during the B100 manufacturing process(8).

MetalsMetals are known to catalyze oxidation and polymerization reactions of hydrocarbons. Heavy metals promote autooxidation(2). Transition metals, such as copper or iron, may be present if corrosion occurs in the manufacturing process and could act as a Lewis Acid to catalyze polymerization of polyunsaturated hydrocarbon molecules found in the B100 or biodiesel blends. Fungible diesels include cracked stocks, such as Light Cycle Oil, which may contain metals and high level of olefins. These cracked stocks, when combined with metals from B100, may decrease stability of the final biodiesel blends. Alkali metals such as sodium, potassium, calcium, and magnesium can form sediments and cause injector failures(4). The alkali metals could form soaps and contribute to insolubles or water haze in the diesel blends. Metals have been shown to have a significant effect in the OSI test, and copper, known to cause instability in petroleum-based fuels, has a significant impact in biodiesel(1). Effective production controls-including neutralization, washing, and water separation-can prevent alkali metal in B100. Proper materials of construction for B100 production equipment can minimize corrosion and the subsequent introduction of metals into the biodiesel. Copper alloys should be avoided in B100 processing equipment. If metal contamination occurs, metal deactivators can be used to chelate transition metals and inhibit the catalytic oxidation and polymerization effects of the metals in the biodiesel.

Unsaturates Much information has been published about the effects of double bonds in various oil feedstocks. Unsaturates are well known as root causes of fuel instability. These molecules are susceptible to oxidation, polymerization, and gum formation. Diesel fuels are blended from cracked feedstocks that contain reactive olefins. The composition of unsaturates in vegetable oils and tallow commonly used in manufacturing B100 are well identified. Vegetable oils are known to contain polyunsaturated fatty acids that are susceptible to oxidation and polymerization reactions. This effect can be seen in Table 2 (page 86). Polyunsturated fatty acids (PUFA) located at the mid position are more stable than if located at the end position(12). The quantity of double bonds can be measured by iodine value, but the location and number of double bonds per molecule cannot be determined. IR or near IR could be a quicker means of paraffin/unsaturation assessment. The IV is in RME (IV-97) compared to the SME (IV-133)(5). As shown in the table, RME, used in Europe, has half to one-third the number of polyunsaturated double bonds compared to SME. Tallow, often used in the USA, has fewer numbers of double bonds and is free of the multiple double bonds, which are found in RME and SME. U.S. biodiesel typically has less than two-hour stability as measured by the OSI test(7). This is well below the European specification of six hours. The primary reasons are the number and position of double bonds.

Unsaturates and polyunsaturates are naturally occurring. The levels can be reduced by hydrotreating; however, this is not economically feasible and would adversely affect the low-temperature fluidity. Antioxidants have been used extensively in the refining industry to prevent the reactions of unsaturates in fuels by inhibiting or interrupting the oxidation and polymerization reactions to prevent degradation, oxidation, and gum formation. Additives can be used to prevent degradation of B100 and biodiesel blends, thus preventing operability problems.

Summary Literature documents the disconnect between stability and operability, including insolubles that cause system pluggage. At this time, there is not a single procedure that can evaluate or predict instability of biodiesel in general or the formation of insolubles in petroleum-based biodiesel blends that are causing operability problems in engines. The quality of B100 is essential to operability.

Reactions can occur in B100 or biodiesel blends to form polymeric gums and degradation byproducts that may result in vehicle operability problems, including fuel-filter pluggage or injector fouling. Quality control of the B100 during manufacturing is critical to preventing these problems. However, some variation in processes and feedstocks may result in B100 that has an increased tendency to form these degradation byproducts. Fuel additives have been used for many decades to prevent and control oxidation and polymerization reactions that contribute to gum formation in petroleum fuels. They act to inhibit metal catalysis, prevent peroxide formation, neutralize acids that can catalyze polymerization reactions, and act as chain terminators for olefinic polymerization processes.

The mechanisms described above have been very well researched and documented. Analytical techniques are available to determine the levels of components that may contribute to B100 instability. The biodiesel blends may become unstable because of interactions of factors that, by themselves, may not be significant but, when combined, are synergistic and increase the instability of the biodiesel blend. Understanding the reaction mechanisms is necessary for the correct application of stability improvers in B100 and biodiesel blends. Fuel additives can be used to counteract and prevent the mechanisms that cause oxidation, polymerization, and acid formation, mitigate the effect of insolubles, and improve the operability of biodiesel blends in diesel.

| biodiesel Engine Safety bio Diesel

Case Study 1:Fuel Additives Improve Biodiesel Stability And Operability A large West Coast fleet of more than 1,300 buses was having problems with filter pluggage using biodiesel. After experiencing severe fuel-filter plugging, which resulted in shutting down many buses in the fleet, the fleet owner contacted the fuel supplier asking for help in solving the problem. The fuel supplier contacted its GE additive specialist and asked for a solution to the problem. GE successfully applied a combination of stabilizer and dispersant to the biodiesel blends used by the fleet, and the results prove that the problem has been solved. The fleet no longer had filter plugging or fuel system failures. In addition, the GE representative recommended a solution to the moisture problem in the B100 as it is manufactured, and fuel with consistently less than 50 ppm water is now being manufactured. Though the moisture in the fuel has been reduced to an acceptable level, biodiesel has an affinity for water, and measures must be taken to control exposure of the fuel to water. GE has also conducted research into the ability of additives to clear up hazy fuel (due to moisture in the fuel) and now recommends an additive that has proven effective in clearing hazy fuel. The fleet has not had fuel-system failures since they began using the stability additive, OTR* 8003.

Case Study 2:Biodiesel, Containing GE OTR 8003, Used With No Operability Problems A Midwest fuel distributor has used GE stability additive in their biodiesel blends when they began marketing this fuel. They have had no filter pluggage or fuel-system-related failures attributed to biodiesel blends.

| biodiesel Engine Safety biodiesel And Vegetable Oil

Diesel Power And B100 BiodieselYou got all that? Don't worry, there won't be a test on the reading material, but we hope this truly in-depth look gives you a better idea about the makeup of biodiesels. Is it safe to use biodiesel in your diesel engine? It all depends on the preparation. Well-made biodiesel should work fine, but a bad batch could leave you with temporary problems such as a clogged fuel filter or plugged injectors, or worse, coking of the injectors and corrosion of engine parts. Until there is a national standard for biodiesel being sold, using it can be a bit of a gamble, but the future looks bright for B100 or blends that are produced within certain specifications.

-The Diesel Power staff

References1. Knothe, G., Dunn R.O. Dependence of Oil Stability Index of Fatty Compounds on their Structure and Concentration and Presence of Metals. JOACS, 2003, 80 (10).

2. Wikipedia, the Free Encyclopedia, http//en.wikipedia.org/wiki/fatty_acid, Autoxidation and Rancidity.

3. Prankl, H.; Schindlbauer, H. Oxidation Stability of Fatty Acid Methyl Esters. 10th European Conference on Biomass for Energy and Industry, June 8-11, 1998, Wurburg Germany.

4. Robert Bosch GmbH. Biodiesel Presentation, CARBbio_29Sept04.

5. Brevard Biodesel, Stability of Biodiesel & Iodine Value, www.brevardbiodiesel.com/10.html.

6. Peckham, J. Biodiesel Blend Instability, Insolubles Formation-Tough to Predict, Fix; ULSD Makes it Worse. Diesel Fuel News, October 10, 2005, 7-11.

7. ASTM Biodesel Subcommittee Presentation. Biodiesel Quality; Test Method Update, Quality Update.

8. Engine Manufacturers Association. Technical Statement on the Use of Biodiesel Fuel in Compression Ignition Engines, page 2.

9. Presentation of BIOSTAB Project Results. Stability of Biodiesel Used As a Fuel For Diesel Engines and Heating Systems, July 3, 2003, Graz, Austria.

10. Clogging Triggers Suspension, Minnesota Halts 2% Biodiesel Requirement Through Jan 13. The OilSpot News by DTN, December 29, 2005.

11. System Lab Services. Determination of Biodiesel Oxidation and Thermal Stability-Final Report, February 12, 1997.

12. Halldorsson, A. Doctorial Thesis, Science Institute, University of Iceland; Lipase Selectivity in Lipid Modification, May 2004.

13. Waynick, J.A. Characterization of Biodiesel Oxidation and Oxidation Products, SwRI Project No. 08-10721, August 2005.

14. PTSA Weekly Update. Truckers Complain that Biodiesel Fuel is Clogging Engine Filters, December 9, 2005.

| biodiesel Engine Safety biodiesel Pump

Biodiesel is getting a lot of attention these days. Many folks are enamored by the fact that it's not made of dead dinosaurs found under countries with unfriendly leaders, but that doesn't automatically mean it's safe to put in your Cummins, Duramax, or Power Stroke engine. General Electric (makers of everything from light bulbs to Late Night with Conan O'Brien to fuel additives) has put together one of the most comprehensive studies of pure 100 percent biodiesel (B100) and its effects on the modern turbodiesel engines we all love. Here are GE's conclusions based on numerous tests that can't be performed by your local bio-fuel co-op.-The Diesel Power staff

Although biodiesel is not a new fuel, commercialization is increasing as regulations promote the use of green fuels in the marketplace. Fuel system failures and operability problems have been encountered as biodiesel use becomes more widespread. Stability issues include understanding the mechanism of degradation of biodiesel and interactions in petroleum-based fuels, determination of stability that predicts operability, and measurement of the degradation. These issues are reviewed and preventative measures are identified for the mechanisms that may contribute to biodiesel instability. Case studies are included to demonstrate how fuel additives are successfully being used to prevent the operability problems in biodiesel fuel blends.

Managing The Stability Of B100 And Biodiesel Blends Blends of biodiesel are now well-adopted fuels that are gaining market share and popularity. Biodiesel is a fuel comprised of mono-alkyl esters of long chain fatty acids derived from vegetable oils or animal fats and meeting the requirements of ASTM D-6751 (a standard set by the American Society for Testing and Materials). However, several unique characteristics of biodiesel, also known as fatty acid methyl esters (FAME) or B100, may cause some operability problems. Low-temperature fluidity, water haze, and thermal and oxidation stability are the most significant issues facing the marketers and end users of biodiesel.

Cold Flow Improver technology is evolving, but, because of the composition of B100 and especially soy oil esters, the improvement using additives is limited to a few degrees Fahrenheit. Understanding the chemical makeup of biodiesel and the measurement of the metrics that could impact operability are key to understanding the root causes of instability and are helpful in formulating solutions to overcome stability problems. The work by J. Andrews Waynick of Southwest Research Institute(13) appears to be the most comprehensive and inclusive document on this subject. Now that fuels containing B100 are being used, experiential information and data can be introduced into the analyses of these critical areas.

The variables that have been identified include glycerol content, free fatty acid content, metals, and carbon-carbon double bond types and configurations (degree and level of unsaturation). The manufacturing process is a significant potential source of stability problems, and process controls are the first line of defense to achieve and maintain biodiesel stability. Fuel-blending strategies and fuel additives are now gaining interest to meet market demands for viable fuels containing biodiesel. Fuel additives are successfully being used to improve operability by preventing oxidation and thermal degradation of biodiesel and blends of biodiesel. For clarification, B100 is used in reference to methyl esters and biodiesel blend is used in reference to blends containing petroleum distillate fuels and B100.

The Manufacturing Process, A Critical Success Factor B100 is produced in a batch process by transesterification of methanol with triglycerides, also known as glycerol fatty acids, in the presence of caustic materials. The degree of completion of the reaction to replace the glycerol with an alcohol such as methanol was recognized as important to fuel quality early in the development of biodiesel. The reaction is conducted at elevated temperatures of around 120-150 degrees Fahrenheit to drive the reaction to completion. The mixture is then neutralized with an acid and washed to remove excess methanol, salts, and free glycerol. Effective neutralization is required to remove alkali metals from the oil phase. If washing is not effective, the salts and glycerol may remain in the B100. Minimizing glycerol levels is required to ensure quality B100 production. Maximizing the degree of completion of the esterification reaction minimizes free fatty acids that can contribute to instability. Removal of alkali metal salts from the process and drying is also important to meet the quality standard of a finished B100 product. Process controls and quality testing are required to achieve the quality standards established in ASTM D-6751. These standards are currently being reviewed based on recent problems with biodiesel blends in the marketplace, and modifications may be recommended to prevent potential operability problems in the future with biodiesel products.

| biodiesel Engine Safety biodiesel Pump

Biodiesel is getting a lot of attention these days. Many folks are enamored by the fact that it's not made of dead dinosaurs found under countries with unfriendly leaders, but that doesn't automatically mean it's safe to put in your Cummins, Duramax, or Power Stroke engine. General Electric (makers of everything from light bulbs to Late Night with Conan O'Brien to fuel additives) has put together one of the most comprehensive studies of pure 100 percent biodiesel (B100) and its effects on the modern turbodiesel engines we all love. Here are GE's conclusions based on numerous tests that can't be performed by your local bio-fuel co-op.-The Diesel Power staff

Although biodiesel is not a new fuel, commercialization is increasing as regulations promote the use of green fuels in the marketplace. Fuel system failures and operability problems have been encountered as biodiesel use becomes more widespread. Stability issues include understanding the mechanism of degradation of biodiesel and interactions in petroleum-based fuels, determination of stability that predicts operability, and measurement of the degradation. These issues are reviewed and preventative measures are identified for the mechanisms that may contribute to biodiesel instability. Case studies are included to demonstrate how fuel additives are successfully being used to prevent the operability problems in biodiesel fuel blends.

Managing The Stability Of B100 And Biodiesel Blends Blends of biodiesel are now well-adopted fuels that are gaining market share and popularity. Biodiesel is a fuel comprised of mono-alkyl esters of long chain fatty acids derived from vegetable oils or animal fats and meeting the requirements of ASTM D-6751 (a standard set by the American Society for Testing and Materials). However, several unique characteristics of biodiesel, also known as fatty acid methyl esters (FAME) or B100, may cause some operability problems. Low-temperature fluidity, water haze, and thermal and oxidation stability are the most significant issues facing the marketers and end users of biodiesel.

Cold Flow Improver technology is evolving, but, because of the composition of B100 and especially soy oil esters, the improvement using additives is limited to a few degrees Fahrenheit. Understanding the chemical makeup of biodiesel and the measurement of the metrics that could impact operability are key to understanding the root causes of instability and are helpful in formulating solutions to overcome stability problems. The work by J. Andrews Waynick of Southwest Research Institute(13) appears to be the most comprehensive and inclusive document on this subject. Now that fuels containing B100 are being used, experiential information and data can be introduced into the analyses of these critical areas.

The variables that have been identified include glycerol content, free fatty acid content, metals, and carbon-carbon double bond types and configurations (degree and level of unsaturation). The manufacturing process is a significant potential source of stability problems, and process controls are the first line of defense to achieve and maintain biodiesel stability. Fuel-blending strategies and fuel additives are now gaining interest to meet market demands for viable fuels containing biodiesel. Fuel additives are successfully being used to improve operability by preventing oxidation and thermal degradation of biodiesel and blends of biodiesel. For clarification, B100 is used in reference to methyl esters and biodiesel blend is used in reference to blends containing petroleum distillate fuels and B100.

The Manufacturing Process, A Critical Success Factor B100 is produced in a batch process by transesterification of methanol with triglycerides, also known as glycerol fatty acids, in the presence of caustic materials. The degree of completion of the reaction to replace the glycerol with an alcohol such as methanol was recognized as important to fuel quality early in the development of biodiesel. The reaction is conducted at elevated temperatures of around 120-150 degrees Fahrenheit to drive the reaction to completion. The mixture is then neutralized with an acid and washed to remove excess methanol, salts, and free glycerol. Effective neutralization is required to remove alkali metals from the oil phase. If washing is not effective, the salts and glycerol may remain in the B100. Minimizing glycerol levels is required to ensure quality B100 production. Maximizing the degree of completion of the esterification reaction minimizes free fatty acids that can contribute to instability. Removal of alkali metal salts from the process and drying is also important to meet the quality standard of a finished B100 product. Process controls and quality testing are required to achieve the quality standards established in ASTM D-6751. These standards are currently being reviewed based on recent problems with biodiesel blends in the marketplace, and modifications may be recommended to prevent potential operability problems in the future with biodiesel products.

| Figure 1: Relationship between B100 and stability(7).

Why is stability important?

| Figure 1: Relationship between B100 and stability(7).

Why is stability important? | Effect Of Stability On ViscosityFigure 2: Relationship between B100 stability and viscosity(3).

The OSI Rancimat has been identified as a procedure to measure stability by quantifying the acids formed during the degradation process when biodiesel is exposed to elevated temperatures and oxygen. It has been used to predict the oxidation stability of biodiesel(7). The references to the data shown in Figure 1 indicated that little correlation exists between stability and insolubles. This conclusion is true for linear correlations. However, the correlation coefficient is higher when using an exponential decay relationship, although the correlation is still weak. This may be due to the data scatter in the top left quadrant that could be caused by variation in significant factors such as metals, glycerol content, unstaurates, polyunsaturates, and acids.

Tests such as the ASTM-525 and ASTM-6418 measure the thermal stability of biodiesel by quantifying the color degradation and gum formation. However, many failures in fuel systems where biodiesel used stability measurements could not predict the formation of solids that cause filter plugging, one of the more common problems with biodiesel.

Long-term storage tests, such as ASTM D-4625, have been used to determine oxidation stability. Using this test, biodiesels have been found to be susceptible to oxidation and sunlight can accelerate the process, although light should not be a problem in the fuel applications(3). The effects of aging in long-term storage tests can be measured by changes in viscosity as shown in Figure 2. The correlation for the equation is relatively high, indicating that the relationship can be predicted based on the available data.

Iodine value (IV) can be used to quantify the number of double bonds, a major cause of instability. However, the position and number of double bonds per molecule are important factors in the stability of B100, and the IV cannot distinguish these parameters. The esterification efficiency and free acids, glycerols, and partially transesterified oils are also important variables that cannot be quantified using the IV, so the IV would not be expected to be a good predictor of stability. The composition and molecular structures the oil feedstocks that are used to make B100 have been clearly identified, and, therefore, IV testing would be useful primarily for determining changes in the base oils from degradation.

The results of aging can be measured by IV, total acid number (TAN), anisidine value (aldehydes), and viscosity(6). Acid number increases as B100 ages; this is the evidence of degradation and not a measure of stability(4). These metrics can only quantify the degree of degradation, but do not predict the stability of B100 or biodiesel blends. As shown in Figure 2 (page 84), the viscosity increases in relation to the stability of B100; this is caused by polymerization reactions that occur in the degradation of B100.

Glycerols

| Effect Of Stability On ViscosityFigure 2: Relationship between B100 stability and viscosity(3).

The OSI Rancimat has been identified as a procedure to measure stability by quantifying the acids formed during the degradation process when biodiesel is exposed to elevated temperatures and oxygen. It has been used to predict the oxidation stability of biodiesel(7). The references to the data shown in Figure 1 indicated that little correlation exists between stability and insolubles. This conclusion is true for linear correlations. However, the correlation coefficient is higher when using an exponential decay relationship, although the correlation is still weak. This may be due to the data scatter in the top left quadrant that could be caused by variation in significant factors such as metals, glycerol content, unstaurates, polyunsaturates, and acids.

Tests such as the ASTM-525 and ASTM-6418 measure the thermal stability of biodiesel by quantifying the color degradation and gum formation. However, many failures in fuel systems where biodiesel used stability measurements could not predict the formation of solids that cause filter plugging, one of the more common problems with biodiesel.

Long-term storage tests, such as ASTM D-4625, have been used to determine oxidation stability. Using this test, biodiesels have been found to be susceptible to oxidation and sunlight can accelerate the process, although light should not be a problem in the fuel applications(3). The effects of aging in long-term storage tests can be measured by changes in viscosity as shown in Figure 2. The correlation for the equation is relatively high, indicating that the relationship can be predicted based on the available data.

Iodine value (IV) can be used to quantify the number of double bonds, a major cause of instability. However, the position and number of double bonds per molecule are important factors in the stability of B100, and the IV cannot distinguish these parameters. The esterification efficiency and free acids, glycerols, and partially transesterified oils are also important variables that cannot be quantified using the IV, so the IV would not be expected to be a good predictor of stability. The composition and molecular structures the oil feedstocks that are used to make B100 have been clearly identified, and, therefore, IV testing would be useful primarily for determining changes in the base oils from degradation.

The results of aging can be measured by IV, total acid number (TAN), anisidine value (aldehydes), and viscosity(6). Acid number increases as B100 ages; this is the evidence of degradation and not a measure of stability(4). These metrics can only quantify the degree of degradation, but do not predict the stability of B100 or biodiesel blends. As shown in Figure 2 (page 84), the viscosity increases in relation to the stability of B100; this is caused by polymerization reactions that occur in the degradation of B100.

Glycerols | biodiesel Engine Safety bio Diesel

Case Study 1:

| biodiesel Engine Safety bio Diesel

Case Study 1: | biodiesel Engine Safety biodiesel And Vegetable Oil

Diesel Power And B100 Biodiesel

| biodiesel Engine Safety biodiesel And Vegetable Oil

Diesel Power And B100 Biodiesel