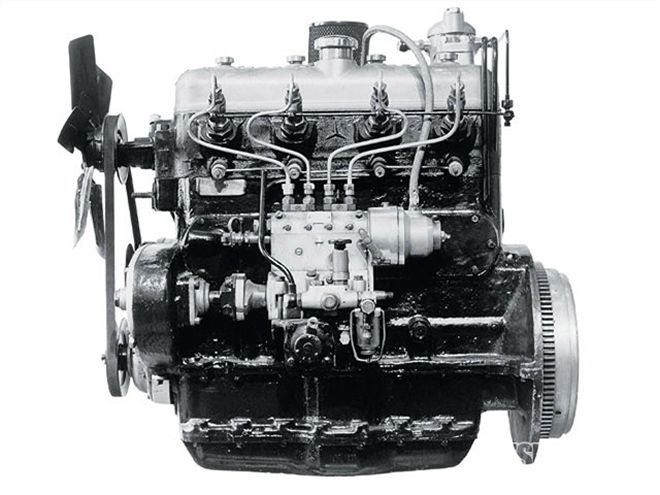

| diesel Engines side Angle

Airflow and Fuelflow through a Four-Stroke Diesel EngineAir flowing into a four-stroke diesel engine gets cleaned as it passes through the air filter. It then flows through tubing until it is compressed in the spinning blades of the turbo. As a result, the air becomes denser and hotter, so it gets cooled down in an intercooler. The intercooler is connected to the air intake of the engine with hoses. As the piston slides to the bottom of its stroke, the combustion chamber fills with air due to the opened intake valve. This is known as the intake stroke. The intake valve(s) close and the piston pushes the air up toward the cylinder head. During this phase, known as the compression stroke, the air takes up approximately 1/16 the space it did before.

A pump (either electrical or mechanical, located in the tank or on the framerail) sends fuel at a low pressure to the injection pump. The injection pump boosts the pressure significantly up to 17,000-30,000 psi. Fuel is then injected into the combustion chamber (filled with superheated air) at a tremendous amount of pressure just before top dead center. The resulting combustion pushes the piston back down. This is called the power stroke. The final cycle happens when the exhaust valve(s) opens and the piston pushes the exhaust out. The exhausted air still has plenty of energy to push the exhaust side of the turbo. Next, the air enters into the exhaust and exits out the tailpipe.

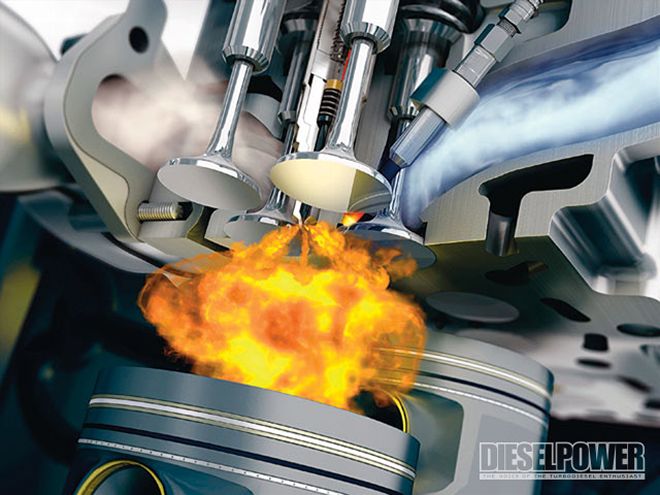

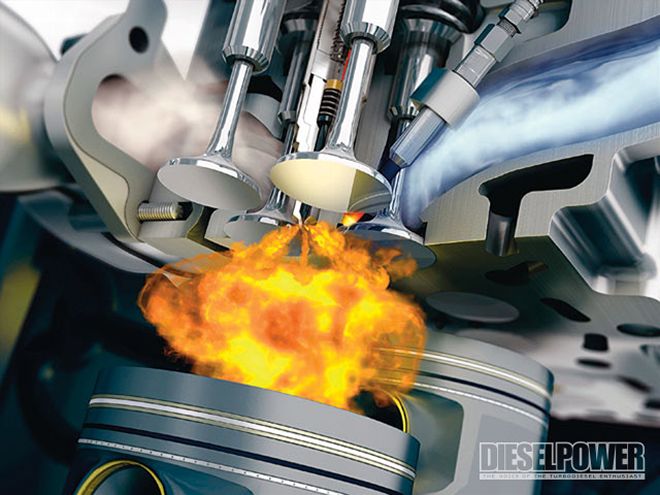

Combustion IgnitionCombustion ignition is a key characteristic of a diesel engine, and the easiest way to explain it is with a fire piston. These ancient fire-starting devices consisted of a piston with a recessed tip, and an air-tight cylinder. When the two are quickly pushed together, the temperature of the air in the cylinder rises high enough to combust a piece of tinder put on the end of the piston. The diesel engine uses the same principle as the fire piston, only on a much larger and more complex scale.

If you have a head for figures, the equation PV=nRT is very useful. This equation defines the relationship between pressures (P), volume (V), amount of gas present measured in moles (n), the universal gas constant (R), and temperature (T). As pressure increases in the cylinder, so does temperature. So when the piston compresses the air inside the cylinder to 1/16 of its original volume, the temperature inside the cylinder exceeds 400 degrees. This is enough heat and pressure to make diesel fuel ignite without the use of spark plugs.

A Closer Look at Diesel CombustionOne of the main differences between a gasoline engine and a diesel engine is the type of combustion performed. A diesel's burn is very complex and uses the same principle as a candle, where fuel and air mix as a result of the combustion. Convection currents and turbulence play a large role in how the unmixed (heterogeneous) fuel is burned. A gasoline engine, on the other hand, mixes the fuel and air completely (homogenous) well before its comparatively simple combustion. One of the downsides to injection gasoline engines is that when the piston compresses the fuel air mixture, some of it gets stuck in the imperfections of the cylinder walls. That is why gasoline engines have higher carbon monoxide (CO) and hydrocarbon emissions compared to diesel engines.

| diesel Engines combustion Ignition

Why does the diesel engine sound so loud?Remember how we just said diesels have an unmixed fuel-air combination? That is not totally true. Some of the fuel does mix with oxygen on the atomic level. These small pockets are like little bombs and are the first to ignite. These premixed (deflagration) waves are known as detonation. This is a violent supersonic flame front, which moves faster than the speed of sound. In the wake of this release of energy, the vast majority of the unmixed fuel burns as a diffusion (non-premixed) flame. So the amount of mixed fuel in the cylinder at the beginning of combustion determines how much noise you will hear. Turbochargers and exhaust gas recirculation (EGR) systems make the diesel quieter.

Why Plug in a diesel?Block heaters use 110 volts to heat the coolant and engine oil, so an engine plugged in on a cold winter's night will start much easier than if left unplugged. A diesel engine holds large amounts of thick oil. Combined with the diesel engine's high compression ratio, these two conditions put great strain on the batteries (whose power is decreased by the cold). Since that is the case, having a hot reservoir of oil in the pan will ensure lubrication is instantly available to reduce friction and make starting easier.

Why Do They Last Longer?Diesel engines last longer because they have a heavy-industry heritage. From this background comes their oil-cooled pistons, mechanical drive on all vital components, forged-steel crankshafts, and heavy reinforcement of high-stress areas like bearing caps. Another reason they last longer is because only air is compressed in a diesel engine's cylinders-not a solvent like gasoline. Plus, diesel fuel acts as a lubricant and is good for the cylinder walls and piston rings. Diesels run at lower speeds because of their mechanical construction and the speed of combustion in the combustion chamber. The speed of combustion is dependent on the time it takes to burn the fuel. The spray pattern, size of droplets, pressure differences at the injector, temperature, and the design of the chamber all affect the rpm capability of a diesel. Since a diesel engine runs at a high compression ratio, it needs a robust block and rotating assembly that can withstand the powerful forces.

How Do Diesels Make So Much Torque and Still Get Excellent Fuel Economy?A diesel engine makes gobs of torque thanks to its high compression ratio. With heat engines, an increase in the pressure difference from a compressed to an uncompressed piston equals an increase in its efficiency and torque output. Another reason for diesel's power is the diesel fuel itself. It contains 15% more energy per gallon than gasoline. Additionally, a diesel engine can run extremely lean and without the pumping losses associated with a throttle. In a gasoline engine, a rich fuel-air mixture is used to keep combustion cool and catalytic converters operating properly. A diesel can run very lean and still have low exhaust gas temperatures.

What is the Difference Between Glow plugs and spark plugs?Almost all diesels use glow plugs or air warmers. These devices use electricity to create heat inside the cylinder when it is cold during start-up. After reaching operating temperature, the engine no longer needs them. Spark plugs, on the other hand, are always needed in a gasoline engine to start combustion.

Interesting Facts about Diesel Engines*They have no throttle; torque is produced by adding more fuel to the engine. Fuel is metered and the air follows.

*Diesels form fewer emissions of carbon monoxide (CO) and hydrocarbons than gasoline engines because fuel does not get stuck in the cylinder walls during the compression stroke since only air is compressed.

*NASA conducted experiments of diffusion flames in zero gravity. They discovered that because there were no convection currents, the flame glowed blue in a perfect circle.

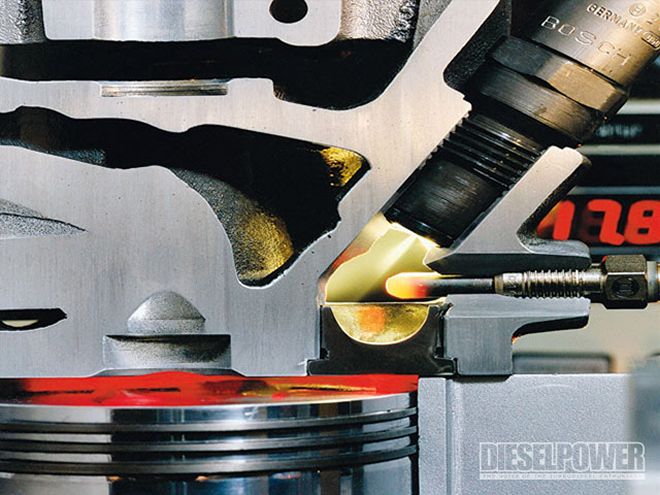

| Used on GM 6.2L and 6.5L, Ford 6.9L and 7.3L (pre-Power Stroke) engines.

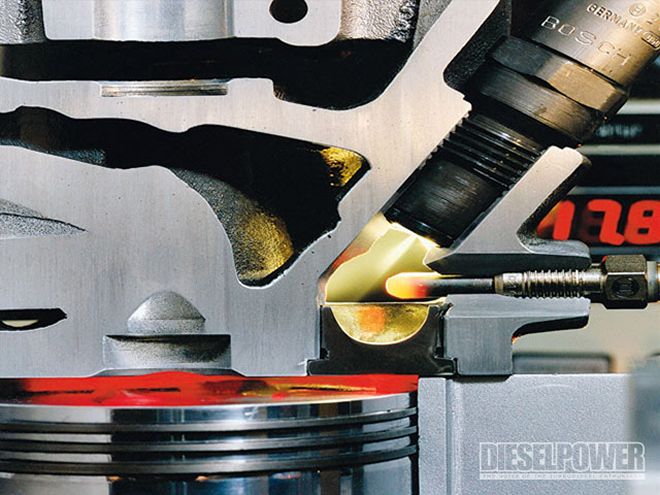

Indirect Injection (IDI)Indirect injection (IDI) consists of a pre-chamber, or swirl chamber, connected to the cylinder's main chamber by a narrow passage. The fuel injector sprays into the smaller chamber, which also houses the glow plug. This is where combustion starts. The pressure differences of the two chambers produces intense turbulence as the two sides strive for equilibrium. IDI engines have lower thermal efficiency than direct ignition (DI) engines. This is because two combustion chambers have more surface area than one. Heat loss in this area is not good for thermal efficiency--it could have gone into pushing the piston down. The energy needed to create the turbulence in the combustion chamber is tallied under pumping losses. A positive feature of the IDI engine is the injection pump does not need to produce high pressures to atomize the fuel.

| Used on 5.9L and 6.7L Cummins, 6.6L Duramax, and 6.0L, 6.4L, and 7.3L Power Stroke engines.

Direct Injection (DI)Direct injection occurs when the fuel injector sprays directly into the combustion chamber only. These engine's pistons are dome shaped, as to create a home for the flame to burn. One of the goals in spraying fuel into the combustion chamber is not hitting the top of the piston or cylinder walls because the temperature drop won't allow the fuel to combust. Direct injection diesels are more efficient, but need high injection pressures in order to support combustion.

DP

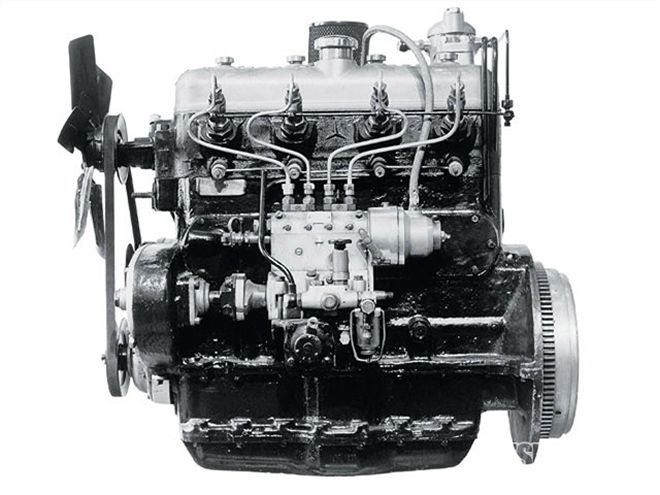

| diesel Engines side Angle

Airflow and Fuelflow through a Four-Stroke Diesel Engine

| diesel Engines side Angle

Airflow and Fuelflow through a Four-Stroke Diesel Engine | diesel Engines combustion Ignition

Why does the diesel engine sound so loud?

| diesel Engines combustion Ignition

Why does the diesel engine sound so loud? | Used on GM 6.2L and 6.5L, Ford 6.9L and 7.3L (pre-Power Stroke) engines.

Indirect Injection (IDI)

| Used on GM 6.2L and 6.5L, Ford 6.9L and 7.3L (pre-Power Stroke) engines.

Indirect Injection (IDI) | Used on 5.9L and 6.7L Cummins, 6.6L Duramax, and 6.0L, 6.4L, and 7.3L Power Stroke engines.

Direct Injection (DI)

| Used on 5.9L and 6.7L Cummins, 6.6L Duramax, and 6.0L, 6.4L, and 7.3L Power Stroke engines.

Direct Injection (DI)