After a six-month hiatus, we've rounded up all the parts needed to tackle the high-pressure fuel system on our 6.4L Power Stroke. In order for the 2008 Ford F-250 to make the 900-rwhp number we want to see, we'll be calling on a set of 100-percent nozzles to get us there. However, knowing that without the ability to maintain adequate rail pressure our horsepower goal would be unreachable, we're also employing two high-pressure fuel pumps. This combination of parts has proven capable of making 1,200 hp and has propelled the Rudy's Diesel Performance Pro Street truck to 9-second quarter-mile times.

The horsepower junkies at Elite Diesel Engineering once again supplied us with top-quality hard parts this month and, in addition to its injector nozzles and Twin K16 system, we'll be running the company's Stage 2 ported fuel rails. Because it has to be installed before the beltdriven K16, one of Elite's Z-Max Jr. intake manifolds will make its way onto the engine. With the high-pressure fueling taken care of this time, we'll move on to the low-pressure system in Part 5. After that, it'll be time to add the turbos and get this thing to the track.

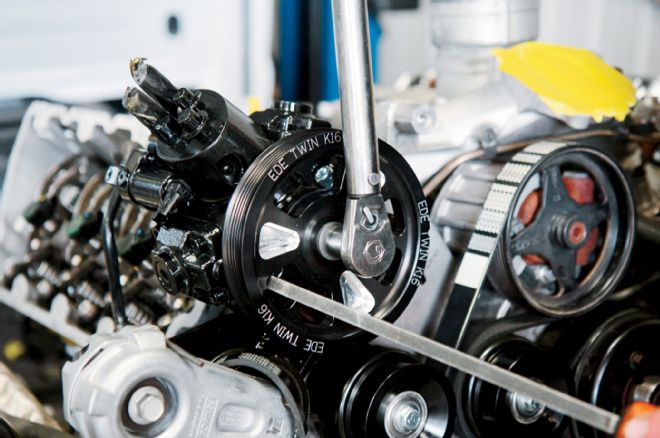

Elite Diesel Engineering's Twin K16 system can be had with a new high-pressure fuel pump ($3,700) or without ($2,600), which is the route we took. Elite's Twin K16 kit comes with new passenger-side high-pressure fuel lines, pulleys (including idlers), a belt tensioner, ¼-inch-thick stainless steel mounting brackets (which we painted gloss black), supply and return fuel hoses, a high-pressure fuel pump wire harness, and all hardware needed to install it.

| 2008 Ford F 250 International Threat Factory Piezo Electronic Injector

Each factory piezo electronic injector in our 6.4L was fitted with an eight-hole, 100-percent-over-stock nozzle from Elite Diesel Engineering. The combination of Elite's 100-percent nozzles and Twin K16 system provides more than enough fuel for 1,000 rwhp, so the 900hp number we want is actually a fairly conservative goal. But at 7,100 pounds, the standard cab Super Duty should be able to get into the 10s in the quarter-mile at the 900hp mark.

| 2008 Ford F 250 International Threat 04

Once the nozzles were fitted to the injectors, the injectors were installed in their respective bores. Not wanting to skimp on a fresh build, we started with brand-new injectors (and glow plugs) from Ford.

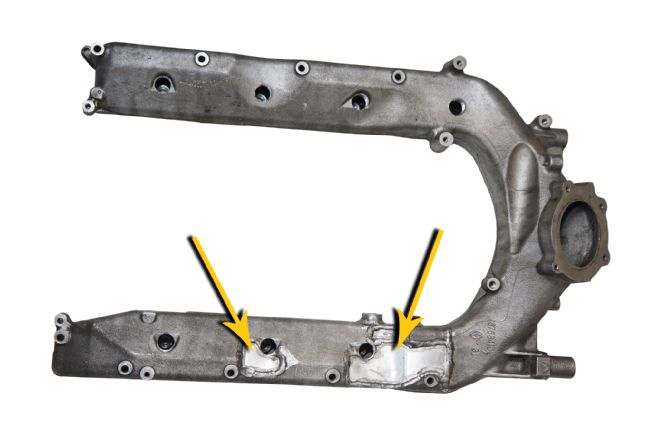

| 2008 Ford F 250 International Threat Elite Diesel Stage 2 Ported Fuel Rails

To increase the volume of fuel making it to the injectors, we're utilizing a set of Elite Diesel's Stage 2 ported fuel rails. The Stage 2 modification goes beyond simply the enlarged inlet and outlets employed in the Stage 1s but increases the rail's overall capacity by 25 percent. More fuel on tap, waiting to be used by the injectors, means more horsepower potential.

| 2008 Ford F 250 International Threat Elite Z Max Jr Intake Manifold

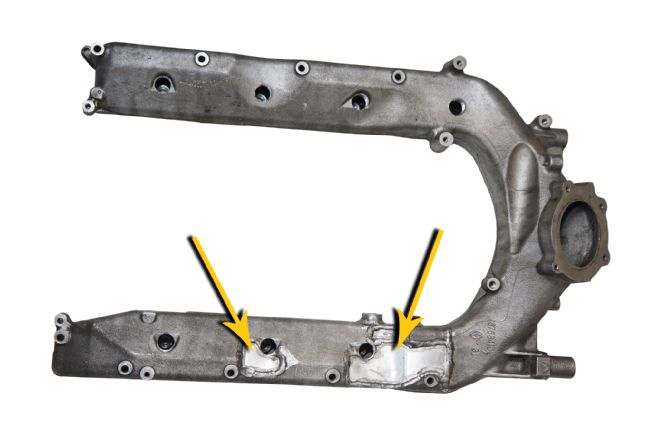

Since we're running stock cylinder heads in our build, Elite's Z-Max Jr. intake manifold was best suited for our needs. The Z-Max Jr. features partial porting to open up the intake passages within the stock manifold, and internal airflow restrictions that exist are removed, such as the fastener bosses. Additionally, the passenger side of the manifold is notched in order to clear a much larger atmospheric turbo in a factory-based compound configuration.

| 2008 Ford F 250 International Threat 05

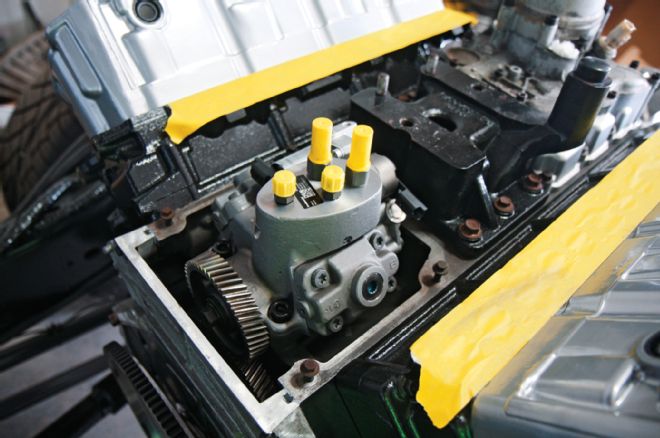

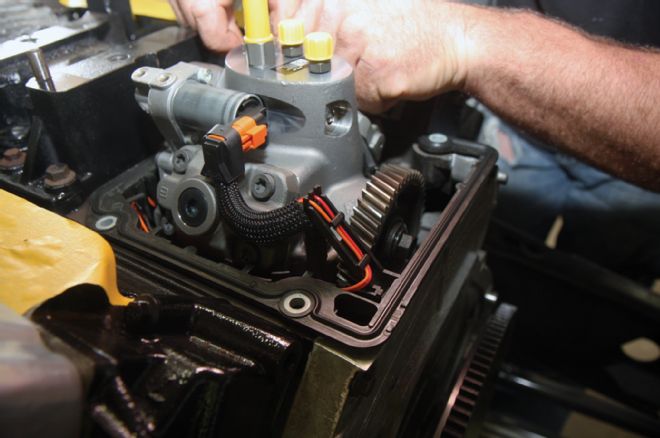

Because our factory K16 only had 62,000 miles on it, we're reusing it, along with a brand-new K16 from the local Ford dealer. The pumps will swap positions, however, with the used pump serving as the front, beltdriven unit and the new pump sitting in the valley. We're doing this for serviceability reasons, in case the used K16 ever has an issue.

| 2008 Ford F 250 International Threat 06

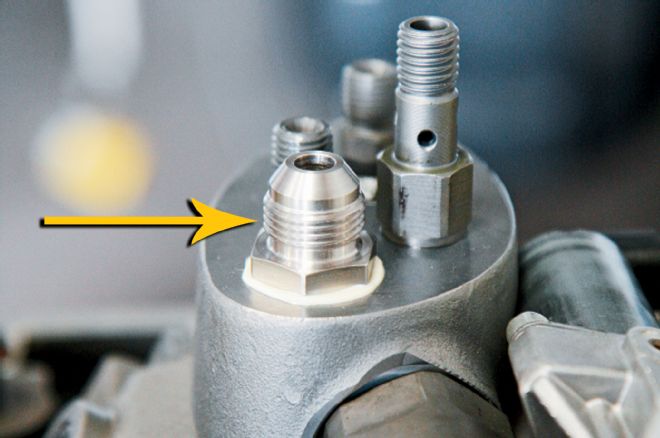

Prior to installing the high-pressure fuel pump cover at the rear of the lifter valley, the feed fitting supplied in Elite's Twin K16 kit was installed. This had to be done first because with the cover on there is no way to get a socket around the fitting. Note: all the K16's fittings are metal to metal (no O-rings).

| 2008 Ford F 250 International Threat 07

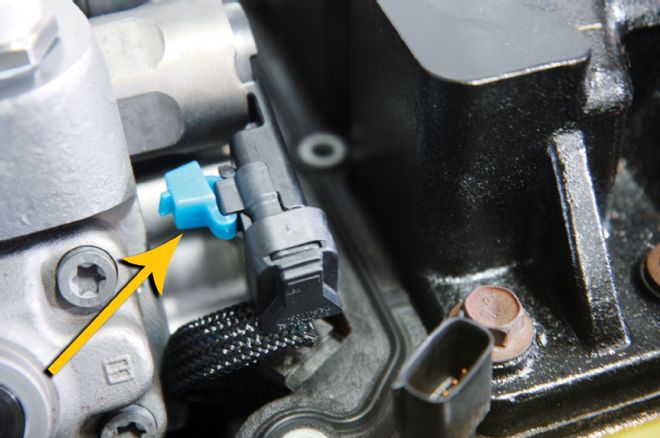

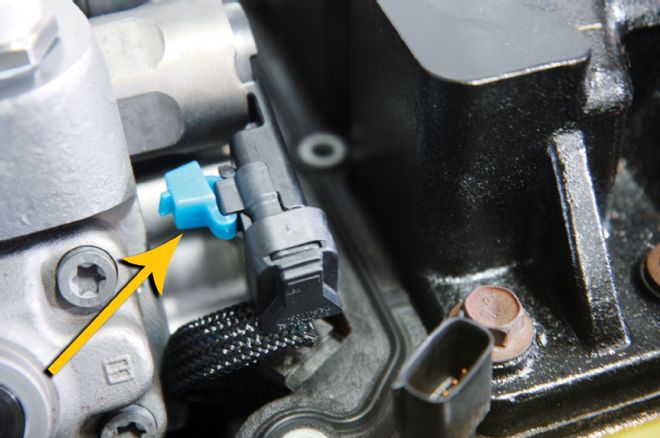

Next, a new high-pressure fuel pump cover kit was installed (PN 8C3Z-9G805-B). This kit stops the wire rub problem that's common on early 6.4L engines by incorporating a mesh wire loom around the wires that rest next to the pump.

| 2008 Ford F 250 International Threat 08

To ensure the high-pressure fuel pump cover wiring harness connection points never unplug (which can happen due to the hot conditions they're exposed to), Ford supplies heavy-duty zip ties that keep the female and male plugs permanently attached.

| 2008 Ford F 250 International Threat 09

After the timing gears were hit with a coating of oil, the rubber gasket was installed in the high-pressure fuel pump cover and it was lowered onto the engine. To clean up the look of the engine, the rocker boxes, valve covers, and high-pressure fuel pump cover were powdercoated silver.

| 2008 Ford F 250 International Threat 10

Elite mills out the factory 6.4L intake manifold bolt bosses when creating the Z-Max Jr. manifold. This opens up the manifold considerably but requires ½-inch pipe plugs installed up top, and Allen bolts internally. Both the pipe plugs and Allen bolts were hit with Loctite before being installed (you don't want the bottom intake manifold fasteners backing out and getting sucked into the engine).

| 2008 Ford F 250 International Threat 11

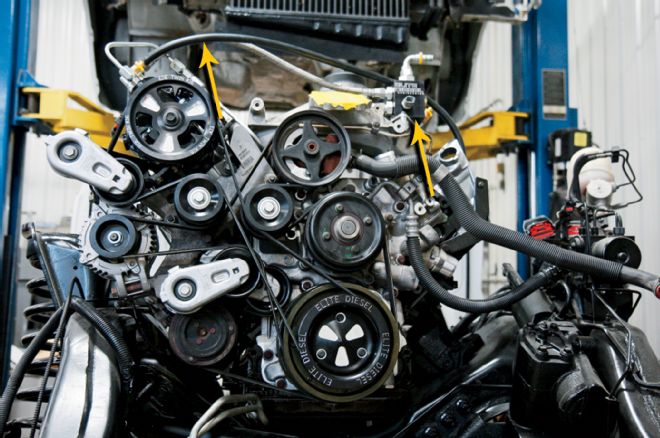

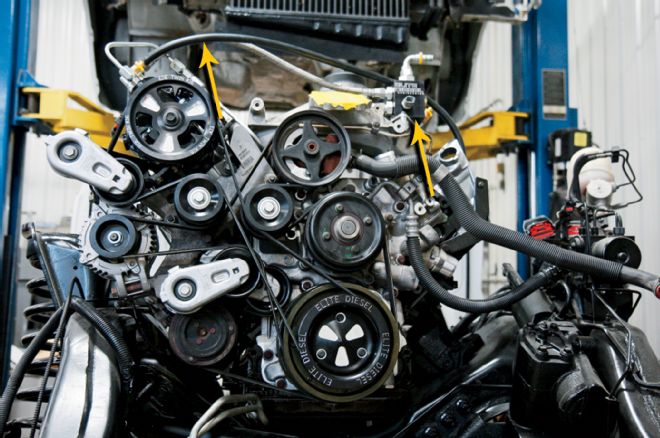

From there, the factory fuel return lines from the heads were installed, followed by the crankcase vent hose, A/C compressor (white arrow), and front accessory bracket.

| 2008 Ford F 250 International Threat 12

After that, the A/C belt tensioner, A/C compressor belt (Gates PN K060400), and alternator were installed (all brand-new), followed by the supplied K16 brackets and Grade 8 bolts. One bracket installs utilizing an engine bracket bolt, and the other bracket connects to the first bracket (and uses the top alternator mounting bolt to secure it). Keep in mind: Once it's all said and done with Elite's Twin K16 kit, there are three belts and tensioners on the engine.

| 2008 Ford F 250 International Threat 13

The supplied idler pulleys install with spacers behind them. This allows the factory serpentine belt to follow its same routing.

| 2008 Ford F 250 International Threat 14

Next up, Elite's crank pulley was installed. It's secured via three anodized bolts (two long and one short bolt).

| 2008 Ford F 250 International Threat 15

Following the install of the second belt tensioner on top of the A/C belt tensioner (red arrow), we added the factory water pump (yellow arrow) and then snaked the serpentine belt into place. In the future (possibly even before the truck's initial startup), we plan to install a Bullet Proof Diesel water pump assembly to hold up under high rpm and live in competition use (it features an aluminum impeller vs. the factory plastic one that's known to crack).

| 2008 Ford F 250 International Threat 16

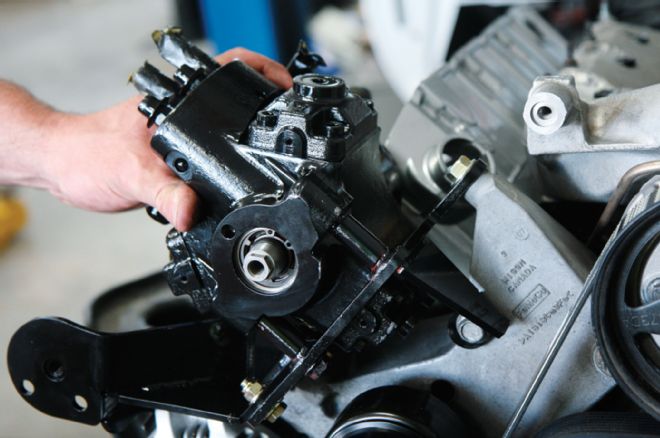

With a fresh coat of gloss black paint, the 62,000-mile factory K16 was placed on the previously installed bracket. Three dowels in the bottom of the pump simply line up with the bosses on the bracket. After that, the third and final belt tensioner, which features a ribbed pulley to drive the K16 pulley, was installed on the K16 bracket.

| 2008 Ford F 250 International Threat 17

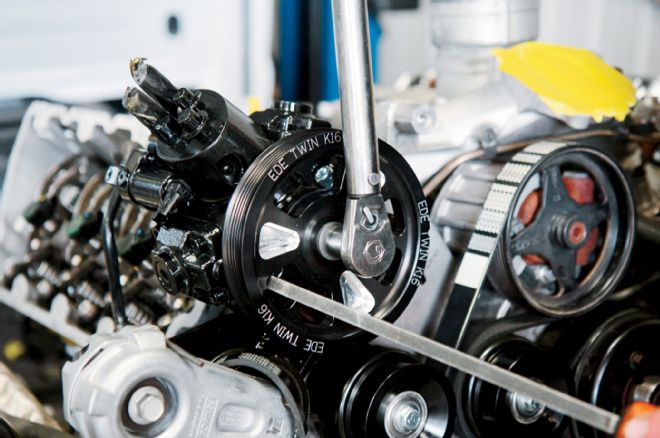

Elite's K16 pulley installs via a reverse-thread mounting bolt, which we torqued to the recommended 58-ft-lb specification. Once tight, the crank-to-K16 belt was fitted to the engine.

| 2008 Ford F 250 International Threat 18

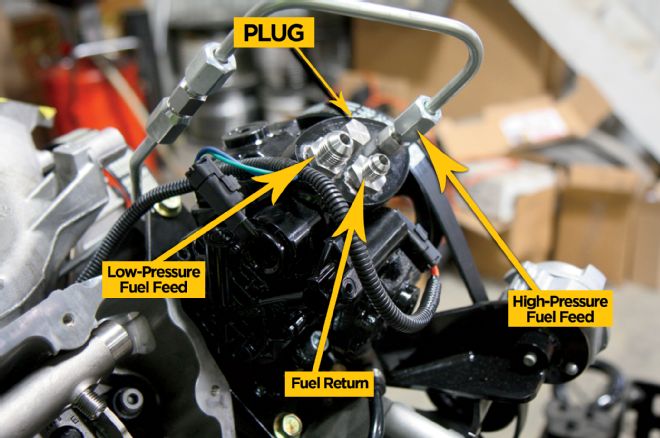

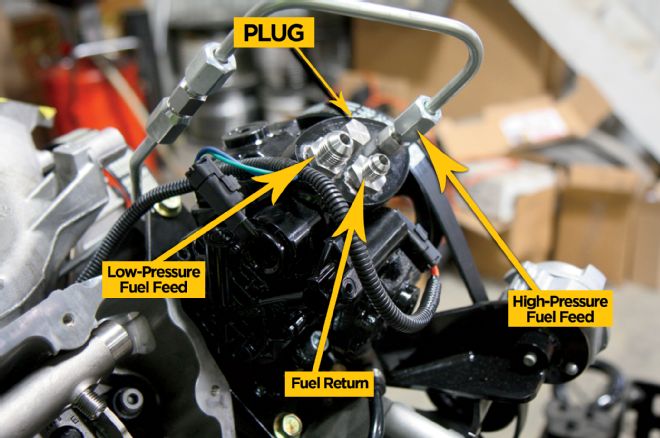

All the factory fittings were removed from the factory K16 pump and replaced with the fittings supplied by Elite. As you can see here, there is only one feed fitting now (instead of two).

| 2008 Ford F 250 International Threat 19

Three of Elite's supplied high-pressure fuel lines meet at the rear of the engine, on the passenger side of the valley-mounted K16. The long, high-pressure feed line running from the front K16 routes along the intake manifold in the valley and tees into a line that runs to the factory location K16 and a line that connects to the passenger-side fuel rail. The driver side of the engine retains all the factory high-pressure feed lines.

| 2008 Ford F 250 International Threat 20

The last order of business was connectingthe supplied high-pressure fuel pump wire harness to the valley-mounted K16 and the primary engine wire harness. This harness allows both fuel control actuators (on the K16 pumps) to share the workload in creating the pressure desired by the the rail pressure sensor. For example, if the rail pressure sensor wants to see 20,000 psi, both K16 actuators will in theory create 10,000 psi apiece.

| 2008 Ford F 250 International Threat 21

With the Twin K16 system now in the books, we'll be moving on to the low-pressure fuel system next time. As you can see here, we've already started mocking it up. Notice the Elite Diesel fuel distribution block, braided supply line, and rubber return hose. Stay tuned for Part 5.

| 2008 Ford F 250 International Threat Factory Piezo Electronic Injector

Each factory piezo electronic injector in our 6.4L was fitted with an eight-hole, 100-percent-over-stock nozzle from Elite Diesel Engineering. The combination of Elite's 100-percent nozzles and Twin K16 system provides more than enough fuel for 1,000 rwhp, so the 900hp number we want is actually a fairly conservative goal. But at 7,100 pounds, the standard cab Super Duty should be able to get into the 10s in the quarter-mile at the 900hp mark.

| 2008 Ford F 250 International Threat Factory Piezo Electronic Injector

Each factory piezo electronic injector in our 6.4L was fitted with an eight-hole, 100-percent-over-stock nozzle from Elite Diesel Engineering. The combination of Elite's 100-percent nozzles and Twin K16 system provides more than enough fuel for 1,000 rwhp, so the 900hp number we want is actually a fairly conservative goal. But at 7,100 pounds, the standard cab Super Duty should be able to get into the 10s in the quarter-mile at the 900hp mark.

| 2008 Ford F 250 International Threat 04

Once the nozzles were fitted to the injectors, the injectors were installed in their respective bores. Not wanting to skimp on a fresh build, we started with brand-new injectors (and glow plugs) from Ford.

| 2008 Ford F 250 International Threat 04

Once the nozzles were fitted to the injectors, the injectors were installed in their respective bores. Not wanting to skimp on a fresh build, we started with brand-new injectors (and glow plugs) from Ford.

| 2008 Ford F 250 International Threat Elite Diesel Stage 2 Ported Fuel Rails

To increase the volume of fuel making it to the injectors, we're utilizing a set of Elite Diesel's Stage 2 ported fuel rails. The Stage 2 modification goes beyond simply the enlarged inlet and outlets employed in the Stage 1s but increases the rail's overall capacity by 25 percent. More fuel on tap, waiting to be used by the injectors, means more horsepower potential.

| 2008 Ford F 250 International Threat Elite Diesel Stage 2 Ported Fuel Rails

To increase the volume of fuel making it to the injectors, we're utilizing a set of Elite Diesel's Stage 2 ported fuel rails. The Stage 2 modification goes beyond simply the enlarged inlet and outlets employed in the Stage 1s but increases the rail's overall capacity by 25 percent. More fuel on tap, waiting to be used by the injectors, means more horsepower potential.

| 2008 Ford F 250 International Threat Elite Z Max Jr Intake Manifold

Since we're running stock cylinder heads in our build, Elite's Z-Max Jr. intake manifold was best suited for our needs. The Z-Max Jr. features partial porting to open up the intake passages within the stock manifold, and internal airflow restrictions that exist are removed, such as the fastener bosses. Additionally, the passenger side of the manifold is notched in order to clear a much larger atmospheric turbo in a factory-based compound configuration.

| 2008 Ford F 250 International Threat Elite Z Max Jr Intake Manifold

Since we're running stock cylinder heads in our build, Elite's Z-Max Jr. intake manifold was best suited for our needs. The Z-Max Jr. features partial porting to open up the intake passages within the stock manifold, and internal airflow restrictions that exist are removed, such as the fastener bosses. Additionally, the passenger side of the manifold is notched in order to clear a much larger atmospheric turbo in a factory-based compound configuration.

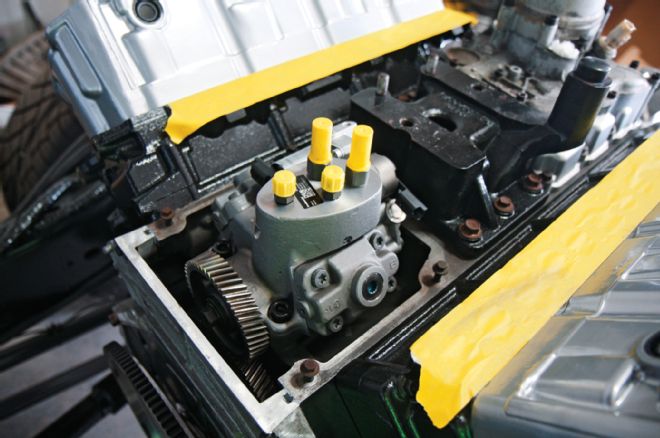

| 2008 Ford F 250 International Threat 05

Because our factory K16 only had 62,000 miles on it, we're reusing it, along with a brand-new K16 from the local Ford dealer. The pumps will swap positions, however, with the used pump serving as the front, beltdriven unit and the new pump sitting in the valley. We're doing this for serviceability reasons, in case the used K16 ever has an issue.

| 2008 Ford F 250 International Threat 05

Because our factory K16 only had 62,000 miles on it, we're reusing it, along with a brand-new K16 from the local Ford dealer. The pumps will swap positions, however, with the used pump serving as the front, beltdriven unit and the new pump sitting in the valley. We're doing this for serviceability reasons, in case the used K16 ever has an issue.

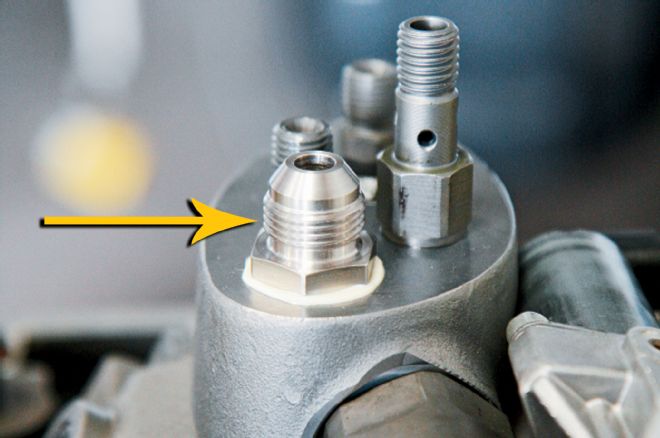

| 2008 Ford F 250 International Threat 06

Prior to installing the high-pressure fuel pump cover at the rear of the lifter valley, the feed fitting supplied in Elite's Twin K16 kit was installed. This had to be done first because with the cover on there is no way to get a socket around the fitting. Note: all the K16's fittings are metal to metal (no O-rings).

| 2008 Ford F 250 International Threat 06

Prior to installing the high-pressure fuel pump cover at the rear of the lifter valley, the feed fitting supplied in Elite's Twin K16 kit was installed. This had to be done first because with the cover on there is no way to get a socket around the fitting. Note: all the K16's fittings are metal to metal (no O-rings).

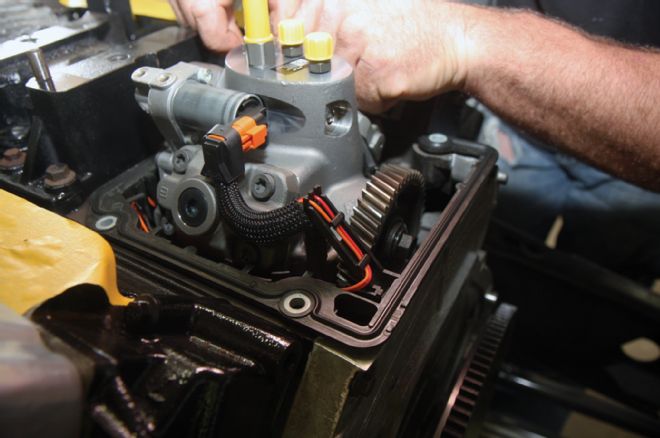

| 2008 Ford F 250 International Threat 07

Next, a new high-pressure fuel pump cover kit was installed (PN 8C3Z-9G805-B). This kit stops the wire rub problem that's common on early 6.4L engines by incorporating a mesh wire loom around the wires that rest next to the pump.

| 2008 Ford F 250 International Threat 07

Next, a new high-pressure fuel pump cover kit was installed (PN 8C3Z-9G805-B). This kit stops the wire rub problem that's common on early 6.4L engines by incorporating a mesh wire loom around the wires that rest next to the pump.

| 2008 Ford F 250 International Threat 08

To ensure the high-pressure fuel pump cover wiring harness connection points never unplug (which can happen due to the hot conditions they're exposed to), Ford supplies heavy-duty zip ties that keep the female and male plugs permanently attached.

| 2008 Ford F 250 International Threat 08

To ensure the high-pressure fuel pump cover wiring harness connection points never unplug (which can happen due to the hot conditions they're exposed to), Ford supplies heavy-duty zip ties that keep the female and male plugs permanently attached.

| 2008 Ford F 250 International Threat 09

After the timing gears were hit with a coating of oil, the rubber gasket was installed in the high-pressure fuel pump cover and it was lowered onto the engine. To clean up the look of the engine, the rocker boxes, valve covers, and high-pressure fuel pump cover were powdercoated silver.

| 2008 Ford F 250 International Threat 09

After the timing gears were hit with a coating of oil, the rubber gasket was installed in the high-pressure fuel pump cover and it was lowered onto the engine. To clean up the look of the engine, the rocker boxes, valve covers, and high-pressure fuel pump cover were powdercoated silver.

| 2008 Ford F 250 International Threat 10

Elite mills out the factory 6.4L intake manifold bolt bosses when creating the Z-Max Jr. manifold. This opens up the manifold considerably but requires ½-inch pipe plugs installed up top, and Allen bolts internally. Both the pipe plugs and Allen bolts were hit with Loctite before being installed (you don't want the bottom intake manifold fasteners backing out and getting sucked into the engine).

| 2008 Ford F 250 International Threat 10

Elite mills out the factory 6.4L intake manifold bolt bosses when creating the Z-Max Jr. manifold. This opens up the manifold considerably but requires ½-inch pipe plugs installed up top, and Allen bolts internally. Both the pipe plugs and Allen bolts were hit with Loctite before being installed (you don't want the bottom intake manifold fasteners backing out and getting sucked into the engine).

| 2008 Ford F 250 International Threat 11

From there, the factory fuel return lines from the heads were installed, followed by the crankcase vent hose, A/C compressor (white arrow), and front accessory bracket.

| 2008 Ford F 250 International Threat 11

From there, the factory fuel return lines from the heads were installed, followed by the crankcase vent hose, A/C compressor (white arrow), and front accessory bracket.

| 2008 Ford F 250 International Threat 12

After that, the A/C belt tensioner, A/C compressor belt (Gates PN K060400), and alternator were installed (all brand-new), followed by the supplied K16 brackets and Grade 8 bolts. One bracket installs utilizing an engine bracket bolt, and the other bracket connects to the first bracket (and uses the top alternator mounting bolt to secure it). Keep in mind: Once it's all said and done with Elite's Twin K16 kit, there are three belts and tensioners on the engine.

| 2008 Ford F 250 International Threat 12

After that, the A/C belt tensioner, A/C compressor belt (Gates PN K060400), and alternator were installed (all brand-new), followed by the supplied K16 brackets and Grade 8 bolts. One bracket installs utilizing an engine bracket bolt, and the other bracket connects to the first bracket (and uses the top alternator mounting bolt to secure it). Keep in mind: Once it's all said and done with Elite's Twin K16 kit, there are three belts and tensioners on the engine.

| 2008 Ford F 250 International Threat 13

The supplied idler pulleys install with spacers behind them. This allows the factory serpentine belt to follow its same routing.

| 2008 Ford F 250 International Threat 13

The supplied idler pulleys install with spacers behind them. This allows the factory serpentine belt to follow its same routing.

| 2008 Ford F 250 International Threat 14

Next up, Elite's crank pulley was installed. It's secured via three anodized bolts (two long and one short bolt).

| 2008 Ford F 250 International Threat 14

Next up, Elite's crank pulley was installed. It's secured via three anodized bolts (two long and one short bolt).

| 2008 Ford F 250 International Threat 15

Following the install of the second belt tensioner on top of the A/C belt tensioner (red arrow), we added the factory water pump (yellow arrow) and then snaked the serpentine belt into place. In the future (possibly even before the truck's initial startup), we plan to install a Bullet Proof Diesel water pump assembly to hold up under high rpm and live in competition use (it features an aluminum impeller vs. the factory plastic one that's known to crack).

| 2008 Ford F 250 International Threat 15

Following the install of the second belt tensioner on top of the A/C belt tensioner (red arrow), we added the factory water pump (yellow arrow) and then snaked the serpentine belt into place. In the future (possibly even before the truck's initial startup), we plan to install a Bullet Proof Diesel water pump assembly to hold up under high rpm and live in competition use (it features an aluminum impeller vs. the factory plastic one that's known to crack).

| 2008 Ford F 250 International Threat 16

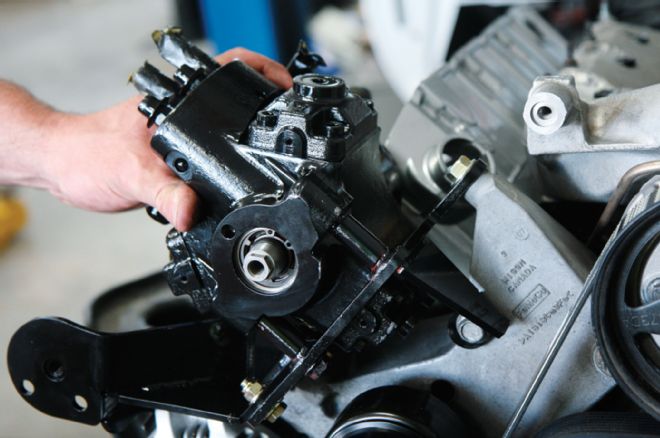

With a fresh coat of gloss black paint, the 62,000-mile factory K16 was placed on the previously installed bracket. Three dowels in the bottom of the pump simply line up with the bosses on the bracket. After that, the third and final belt tensioner, which features a ribbed pulley to drive the K16 pulley, was installed on the K16 bracket.

| 2008 Ford F 250 International Threat 16

With a fresh coat of gloss black paint, the 62,000-mile factory K16 was placed on the previously installed bracket. Three dowels in the bottom of the pump simply line up with the bosses on the bracket. After that, the third and final belt tensioner, which features a ribbed pulley to drive the K16 pulley, was installed on the K16 bracket.

| 2008 Ford F 250 International Threat 17

Elite's K16 pulley installs via a reverse-thread mounting bolt, which we torqued to the recommended 58-ft-lb specification. Once tight, the crank-to-K16 belt was fitted to the engine.

| 2008 Ford F 250 International Threat 17

Elite's K16 pulley installs via a reverse-thread mounting bolt, which we torqued to the recommended 58-ft-lb specification. Once tight, the crank-to-K16 belt was fitted to the engine.

| 2008 Ford F 250 International Threat 18

All the factory fittings were removed from the factory K16 pump and replaced with the fittings supplied by Elite. As you can see here, there is only one feed fitting now (instead of two).

| 2008 Ford F 250 International Threat 18

All the factory fittings were removed from the factory K16 pump and replaced with the fittings supplied by Elite. As you can see here, there is only one feed fitting now (instead of two).

| 2008 Ford F 250 International Threat 19

Three of Elite's supplied high-pressure fuel lines meet at the rear of the engine, on the passenger side of the valley-mounted K16. The long, high-pressure feed line running from the front K16 routes along the intake manifold in the valley and tees into a line that runs to the factory location K16 and a line that connects to the passenger-side fuel rail. The driver side of the engine retains all the factory high-pressure feed lines.

| 2008 Ford F 250 International Threat 19

Three of Elite's supplied high-pressure fuel lines meet at the rear of the engine, on the passenger side of the valley-mounted K16. The long, high-pressure feed line running from the front K16 routes along the intake manifold in the valley and tees into a line that runs to the factory location K16 and a line that connects to the passenger-side fuel rail. The driver side of the engine retains all the factory high-pressure feed lines.

| 2008 Ford F 250 International Threat 20

The last order of business was connectingthe supplied high-pressure fuel pump wire harness to the valley-mounted K16 and the primary engine wire harness. This harness allows both fuel control actuators (on the K16 pumps) to share the workload in creating the pressure desired by the the rail pressure sensor. For example, if the rail pressure sensor wants to see 20,000 psi, both K16 actuators will in theory create 10,000 psi apiece.

| 2008 Ford F 250 International Threat 20

The last order of business was connectingthe supplied high-pressure fuel pump wire harness to the valley-mounted K16 and the primary engine wire harness. This harness allows both fuel control actuators (on the K16 pumps) to share the workload in creating the pressure desired by the the rail pressure sensor. For example, if the rail pressure sensor wants to see 20,000 psi, both K16 actuators will in theory create 10,000 psi apiece.

| 2008 Ford F 250 International Threat 21

With the Twin K16 system now in the books, we'll be moving on to the low-pressure fuel system next time. As you can see here, we've already started mocking it up. Notice the Elite Diesel fuel distribution block, braided supply line, and rubber return hose. Stay tuned for Part 5.

| 2008 Ford F 250 International Threat 21

With the Twin K16 system now in the books, we'll be moving on to the low-pressure fuel system next time. As you can see here, we've already started mocking it up. Notice the Elite Diesel fuel distribution block, braided supply line, and rubber return hose. Stay tuned for Part 5.