Question Defect clutch

Defect clutch

QUESTION: Hi!

I have an 1965 mgb with overdrive. About 5 years ago I had the clutch changed and last year I took the gearbox out and and had i renovated by an expert. Afterwards I reinstalled engine and gearbox. About a mount after (aprox. 1-200 miles)the clutch started to act differently when I stepped on it and about 500 miles later it simply didn't work. At first I thought it was the master cylinder and I changed that. That worked for a few weeks. Then I diconnected the slave cylinder and found that the "stick" going in to the clutch moves freely from side to side.

My question is -What could be wrong? And.....any chance it can be fixed without taking the engine and gearbox out of the car again... :-)

Best regards

Miller

Clutch Arm

Clutch Arm

ANSWER: Hi Miller,

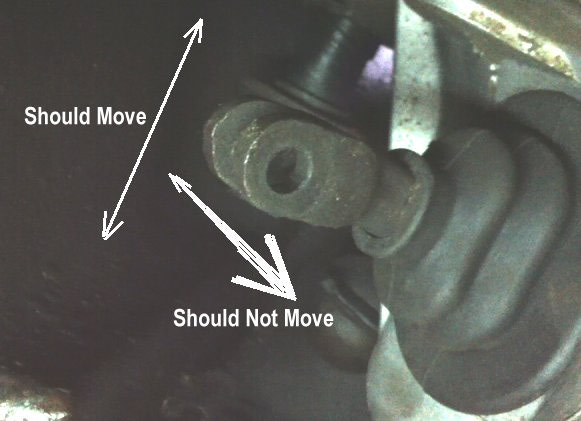

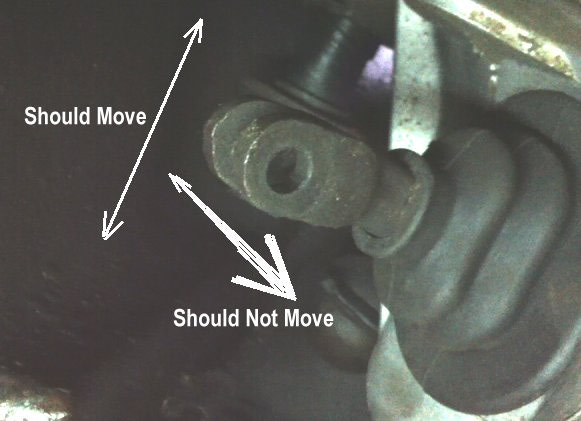

Your picture is of the clutch release arm and it should move forward and to the rear (in line with the car) but not much at all from side to side. This is the clutch release arm and can only make the clutch disengage not engage. The clutch (disk) is engaged all the time because it is clamped to the flywheel by the pressure plate.

That arm is pushed forward very hard by the slave cylinder rod when you depress the clutch pedal. The other end of the arm is fork shaped and it pushes on a carbon release bearing which contacts the center pad on the pressure plate which releases the clamping pressure of the pressure plate, thus releasing the clutch disk which is connected to the gearbox by a splined shaft.

You need to clarify what you mean when you say "It simply didn't work". Did you mean the clutch did not release? Meaning you can't get it into gear with the engine running due to gear clash? Or do you mean you can get it into gear but when you let the clutch out the car does not move?

Here is a typical preliminary test of the clutch system. First put the car in 1st gear (engine not running) hand brake off try to roll the car forward and to the rear. It should only move slightly. Now depress the clutch pedal. The pedal should have about only one inch free play and then feel hard to push and feel the same resistance all the way to the floor. With the pedal on the floor have someone try to push the car. It should move but a little hard to push.

Now hold the pedal on the floor for at least two full minutes and then have someone push the car again. It should move as before.

Since you said that you replaced the master cylinder and it worked for a short time it sounds like you are having release problems. If your pedal is soft and easy to push first look in the master cylinder reservoir at the fluid level. If it is very low add brake fluid (DOT 4 ONLY) then pump the pedal in slow long strokes and check the fluid again and keep it full. If it was soft and when you added fluid it started to feel firm and if pumping for several minutes it pumped up to feel correct you had a fluid leak so check for fluid leakage at the slave cylinder and feel the back side of the pedal arm to see if there is any fluid on it. Which is an indication of a master cylinder leakage.

As far as the clutch arm in the bell housing I have made notes on your picture to show what movement is normal.

Howard

---------- FOLLOW-UP ----------

QUESTION: Hi Howard!

Thank you very much for your quick answer.

The clutch release arm moves back and forth and not to the sides, as you so fine describes in the picture. However there is no resistance when I push/pull.

When I wrote that the clutch simply doesn't work, it means that I can not start the car -My observation is that the clutch doesn't work and the engine is engaged with the wheels and therefore can not start.

Now writing this I can see it seems unlikely that this can be fixed without pulling the engine out again. However, would you have any suggestions to what the problem could be?

Best regards

Miller

Clutch Arm2

Clutch Arm2

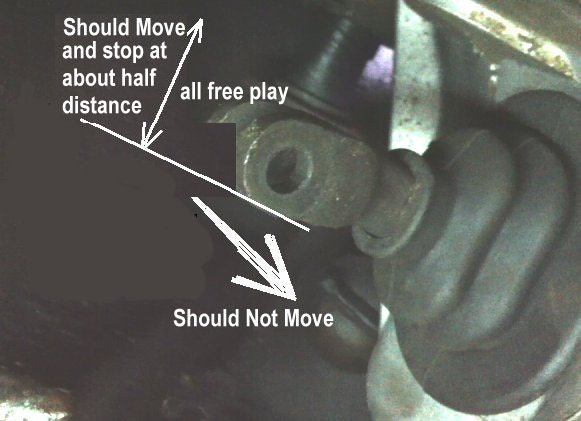

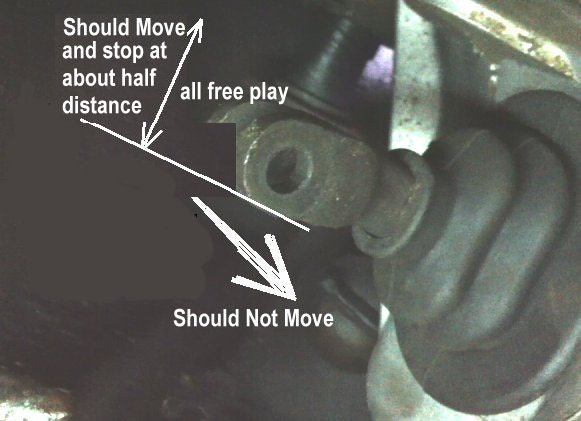

ANSWER: No, you still don't have enough information to decide to pull the engine yet. The clutch arm should move freely but only about half of the travel. If you pull the rubber boot loose from the bell housing you can see what half travel is. Look at the modified picture enclosed.

When you say that you can't start the car because it is in gear all the time you mean that you can't get it into any gear from neutral after you "Start the engine" ???? You can always start the engine while in neutral.

A simple test of the clutch operation is to put the transmission into 4th gear, hand brake off and put the car on a lift or jack stands and pull the rubber boot out of the bell housing and insert a long pry bar (about a foot and a half to two foot long) into the bell housing in FRONT of the clutch arm and pry the clutch arm towards the rear. You should feel that the clutch arm is strong spring loaded. While you hold the clutch arm toward the rear, have someone hold one rear wheel steady while another person rotates the other rear wheel in either direction. If they can see the drive shaft rotating then there probably is nothing wrong with the clutch and all your trouble is in the hydraulics, master cylinder and / or slave cylinder.

It is often difficult to bleed all the air out of the clutch hydraulic system and that will make the clutch not release.

Let me know.

Howard

---------- FOLLOW-UP ----------

QUESTION: Hallo again!

Thank you so very much for your advise. I am truly grateful. I must admit that I was ready to pull out the engine to get to the gearbox, and would probably have done so if not for your advise!

Now the trees doesn't grow all the way into the skies but things certainly seems more positive at this point.

This weekend I did more or less as you instructed -and to my pleasant surprise I could turn the wheel! I reinstalled the slave cylinder, bleed the system and tried pressing the clutchpedal -not much success! After some investigation -I realized that the pin going in and out of the slavecylinder seemed too short. It was simply pushed so fare out of the slvecylinder that I (when removing the rubber)could see the piston going out. I drilled a small hole in a coin with approx. the same diameter as the slave piston and slipped it in in front of the piston. Now I can start the car in neutral and there is a very small area when I step on the clutchpedal where I can change gear. However something is still wrong. If I press the pedal too far it will result in a very unpleasant "squeilling" noise, witch is exactly the problem last summer before it stopped working all together. The area where I can change gear is a little over half way down when I step on the pedal and the area is within less of a quarter of an inch before the squalling sound.

I don't know if you have any idea what might be the problem. I am pretty sure I bleed the system correct and got all air out.

Anyway the sun was shining from a clear blue sky here in Denmark this Sunday and I went for a drive for the first time in almost a year so that was great!

Thanks again, and let me know if you need more information!

Best regards

Miller

AnswerI believe your original problem was air in the hydraulic system thus you were unable to disengage the clutch and now you have corrected that and since you had to extend the slave cylinder rod to make it disengage and you get a noise when fully depressing the clutch pedal.

This is an indication that the carbon block clutch release bearing is worn thin. The release bearing is not a bearing per say. It is a carbon block and when it wares thin you loose reach on the clutch arm. Unfortunately you do need to remove the engine to access it.

We always replaced every thing in the clutch when we have to go inside. Even if only one piece is bad. You should also check the size of the pilot bearing in the back of the crankshaft while you are in there.

In the dealerships I worked in we put a lot of clutches in. As many as 3 or 4 a week for several years. Doing that many I got good at it and other mechanics in one dealership I worked in timed me once and I was able to remove an MGB engine in 35 minutes. It took longer then that to put it back but if you work steady and you will find it not that hard to do.

Only remove the engine but support the front of the gearbox when removing the engine only. You may need a few extra tools then what come in a set of hand tools but it is well worth purchasing them. For example a 90 degrees open-end 1/2 inch wrench and a long extension for your 3/8 drive or 1/2 drive and a 6 point socket for the exhaust pipe to manifold nuts. 12 point sockets can round the nut off and then they are difficult to remove. Be careful not to fray the ends of the throttle cable or choke cables when removing them.

Howard