Car engine manufacturers have developed many different methods of installing a timing chain. Some chain set-ups are very easy to get right, while others are complex and equally easy to get wrong. Because of the complexity of setting the chain precisely, and the fact that being off one link will prevent the car from running properly, it is critical that proper procedures be followed. This is a good introduction to these procedures, but always be sure that you refer to a repair manual that is specific to your particular engine.

Count the number of gears that the chain will fit. If it is only two, like an early model Ford or Chevrolet V-8 engine, this job is not difficult. Each gear is marked in some way. This mark is used as an indicator that aligns to some reference point, usually on the engine. In this case, there are no engine marks because the reference points are the marks on gears. The crankshaft gear, which drives the entire timing chain, and the camshaft gear are synced together by the chain. They are in time when the small dots on the gears align with each other. The camshaft also has a reference pin that the cam gear fits over, then it is bolted into place. This guarantees that the cam timing is correct, and the timing chain is properly fitted.

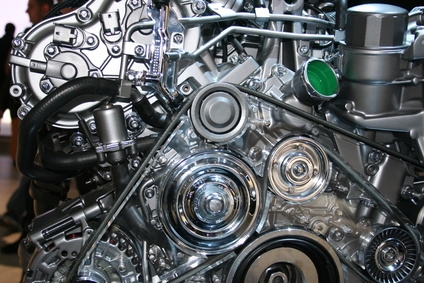

Inspect the timing chain. Short, two-gear chains are not marked. Long, multiple-gear chains are normally marked in some way. Several links may be colored differently than the rest, or have some form of identifying them as key links that are installed in a specific location. The colored links increase the precision required for installation on multiple-gear arrangements found on dual overhead-cam engines. Each colored link is matched to a specific gear, and an exact number of links is counted between the colored link. Further, specific colored links must fit on specific gears. For example, a colored link fits onto a marked tooth on the crankshaft gear. An exact number of links is then counted to reach another colored link. This link then fits onto a marked overhead-cam gear. This process is repeated until the entire chain is installed.

Rotate the engine using a break-over bar after the chain is installed. Use a 1/2-inch socket that is fitted to the crankshaft bolt and rotate the engine one full revolution. Reinspect all of the timing marks. Any mistakes will show up after this process. It's very easy to misalign the chain or a gear, and being off by one tooth will allow the engine to run, but poorly. It will have a poor idle and misfire because the cam timing is incorrect. The rotation procedure prevents this.