Bearings allow free movement of machine parts. The sleeve or journal bearing is a simple bearing used for big-end machines, main crankshaft bearings for cars and computer peripherals. Sleeve bearings are made from hard metals like bronze and beryllium copper. The bearing is a hollow cylinder split into two halves. The sleeve lines a shaft's surface and the bearing is oiled to prevent grinding and abrasion. The shaft rotates and is lubricated within the sleeve.

Silence is golden, or at least it's the ideal situation for the operation of a sleeve bearing. The bearing is designed so that the rod inserted in the shaft does not come into contact with the sleeve. In essence, no contact, no noise. The rod sits on a thin layer of oil and rotates as it rises up. If there is no oil between the rotating shaft and the sleeve, friction will cause the bearing material to dissolve.

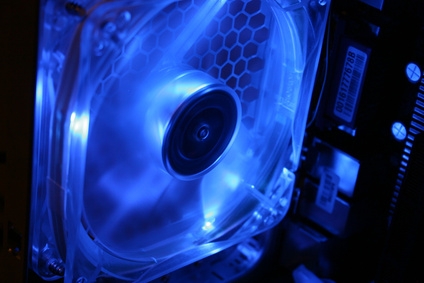

Sleeve bearings are also used often in computer peripherals like power supply fans. The bearings are thick cylinders with a high tolerance internal shaft space that is saturated with oil. Thirty-five percent of the oil's volume travels within the sleeve through interconnecting pores. Sleeve bearings must have sufficient lubricants to operate efficiently. As the rod swivels within the sleeve, if there is no oil, there's no hindrance to contact between the metal parts. Sleeve bearings are known to fail for three main reasons: worn-out bearing, decreased fan speed and total failure. All of these problems are related to a lack of lubrication.

The bearing gets worn out because there's not enough oil or there's an imbalance in the rotational component. While rotating, the rod will become noisy as it vibrates. When this happens, try replacing the bearing first, but more than likely, you'll have to replace the fan.

The fan helps to cool a computer's power supply or CPU. Functionality of the bearing is hindered if the oil partially evaporates or the oil becomes thick and sticky. This can cause the fan blades to rotate at a lower than normal speed, which creates a soft failure.

Overheating can make a fan inoperable. A complete failure occurs when there is no oil in the rotational component or thick and sticky oil overwhelms the fan motor's rotational power. The fan won't operate at all and the device the fan is supposed to cool will overheat. Power supply fans suck in a lot of dust and they operate at very high temperatures so complete failure is a fairly common occurrence for this device.