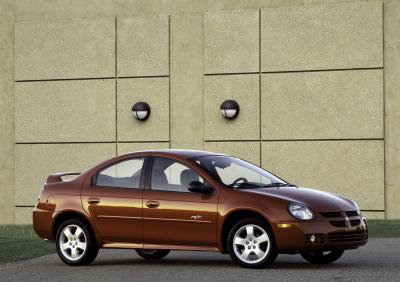

The Neon arrived in Dodge’s showrooms after an advertising campaign – the “Hi” ads – depicting the Shadow’s replacement as a fun-loving economy car. When its 1995 release finally rolled around, the Neon didn’t disappoint, with its sporty appearance and peppy 132-horsepower engine. The 2002 Neon retains the same basic styling of the 1995, just modernized slightly. Two engine mounts, called torque struts, hold the engine in place and allow for slight flexing under heavy acceleration. Replacing these torque struts is fairly simple, but the alignment process can be time-consuming.

Remove the bolt securing the torque strut its mount on the passenger side strut tower using a ratchet and socket.

Unfasten the bolt attaching the torque strut to the engine block.

Pull the torque strut from the engine compartment. Lightly strike the torque strut with a rubber mallet if it does not pull out easily.

Set the torque strut into its mount and hand-thread its retaining bolt.

Pivot the torque strut until it meets the engine and hand-thread the torque strut-to-engine bolt. Tighten the torque strut-to-engine bolt to 87 foot-pounds, using a torque wrench and socket.

Proceed to the “Removing Lower Torque Strut” section if you are replacing the lower torque strut too. If you are only replacing the upper torque strut, proceed to “Adjustment Procedure.”

Loosen the lug nuts on the passenger side front tire with a ratchet and socket. Raise the front of the Neon with a floor jack and slide jack stands under its subframe. Lower the vehicle onto the jack stands. Remove the passenger side front lug nuts and pull the wheel from the vehicle.

Remove the three bolts securing the drive belt splashguard inside the passenger side front wheel well using a ratchet and socket. Remove the splashguard.

Set a 6-inch-long 2-by-4-inch block of wood on the floor jack’s jacking plate. Position the floor jack under the engine side of the transmission bell housing and raise the jack until it contacts the bell housing.

Remove the two nuts that secure the pencil strut – the metal bar that runs from the subframe to the lower torque strut’s bracket on the crossmember – with a ratchet and socket, then remove the pencil strut. Pull the pencil strut’s washer off the lower torque strut’s bolt.

Remove the bolts securing the lower torque strut to the crossmember and its bracket on the engine using a ratchet and socket. Pull the lower torque strut from the engine compartment.

Guide the lower torque strut into its mount in the crossmember and hand-thread its retaining bolt. Pivot the torque strut upward and align its bolt hole with that in its bracket on the engine.

Hand-thread the torque strut-to-engine bracket bolt, then tighten just this bolt to 87 foot-pounds with a torque wrench and socket.

Proceed to “Adjustment Procedure.”

Look on the upper torque strut’s mount and find the bracket securing the rubber hose. Pry this bracket upward with a flathead screwdriver, exposing the hole beneath it; the center of this hole is your bracket reference point.

Look at the bracket on the engine that the upper torque strut connects to. Find the rearmost retaining bolt on this bracket; the center of the bolt head is your engine reference point.

Follow Steps 1 through 3 in “Removing Lower Torque Strut,” if needed.

Remove the upper torque strut-to-bracket bolt and lower torque strut-to-crossmember bolt by hand.

Instruct an assistant to hold a ruler with millimeter measurements spanning the gap between your bracket reference point and engine reference point. Raise or lower the jack until the gap between your two reference points is 119 mm.

Hand-thread the upper torque strut-to-bracket bolt and torque it to 87 foot-pounds with a torque wrench and socket. Hand-tighten the lower torque strut-to-crossmember bolt, then torque it to 87 foot-pounds.

Install the pencil strut’s washer onto the torque strut’s bolt and guide the pencil strut onto its two mounting bolts. Hand-thread the pencil strut’s retaining nuts, then tighten them with a ratchet and socket.

Lower the jack and remove the block of wood.

Reinstall the splashguard in the passenger side front wheel well and tighten its bolts with a ratchet and socket. Install the wheel on the right-front hub and hand-tighten the lug nuts. Raise the Neon off the jack stands, using a floor jack, and remove the jack stands. Lower the Neon to the ground. Tighten the lug nuts, in a crisscross pattern, to 100 foot-pounds.

Align the clip on the rear of the washer fluid hose bracket with its hole in the upper torque strut bracket and press it downward to lock it into place.