Air flow switches detect flowing air conditions in ducts, pipes, tubes and spaces and provide discrete electrical outputs to control systems. There are configurations for every range of air flow from the hint of a whisper to hurricane force gales. Electrical outputs include every type of mechanical switch as well as NPN and PNP solid state switched outputs. Air flow switches are customarily used in Heating Ventilation and Air Conditioning Systems (HVAC) as well as many appliances and industrial venues for safety and operational interlock controls.

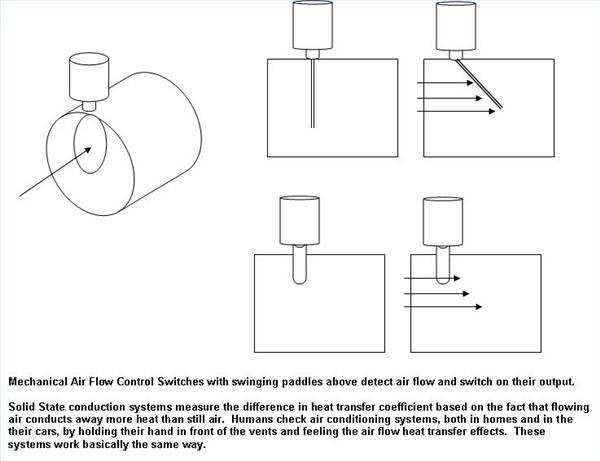

The simplest air flow switches use "sails" or wind paddles to detect air flow in ventilation ducting and plenum chambers. More sophisticated technologies use fee spinning paddles, fan and turbine blades, and high-end industrial units use a calorimetric principle, where a net change in the heat transfer coefficient of the flowing gas is sensed. In the case of flow, more heat flows from the sensing element than without a flow. The most resolute of units use a draft differential pressure principle where air movement where a pressure differential of less than 1/5 inch of water may be sensed.

Air flow switches are commonly used in air ducts of HVAC systems to acknowledge the flow of air to various areas of a building. The importance of this knowledge is both operational and safety related. System operators want to know that air is flowing through a subsystem if the air is being heated or cooled. With incorrect system loading, heat exchangers providing the heating or cooling may overheat or freeze solid without adequate airflow to conduct the heating or cooling BTUs.

Many industrial situations demand that there is adequate airflow through an area to prevent the accumulation of noxious or even deadly gases or fumes. Mines, steel mills, paper mills, and other heavy industries must have a continual flow of air to keep workers breathing healthy air. Safety air flow switches are used in these exhaust and circulation systems to assure that the correct air flow environment is being maintained. Industrial boilers using liquid, gaseous, or solid fuels have a minimal airflow to prevent explosions or asphyxiation of operators.

Many forced air ventilation systems have air flow switches to assure the flow of air into the oil or gas combustion chamber, as well as through the heating plenum, or distribution ducting.

Electrical outputs of air flow switches turn lights on and off, start back up blowers, and input into advanced building control computer systems. Some systems in explosive environments even use pneumatic on-off outputs.

If you have ever wet the tip of your finger and held up to the air, or looked at the leaves of trees in a breeze, you understand the principle of air flow sensors.