Few modifications can make a bigger difference to the power, torque, and fuel mileage derived from your engine than changing the camshaft. The 4.0L in our '89 Jeep Cherokee had 130,000 miles on the clock, but the venerable six-cylinder engine was still running strong with good compression. All hot-rod owners will tell you a camshaft change really perks up any V-8, but we wondered how a peppier cam would work on the inline-six. After speaking with the tech line folks at COMP Cams, we decided to give the Xtreme 4x4 camshaft (PN 68-232-4) a shot. The increased lift and duration would provide a denser charge into the combustion chamber and, hopefully, result in a more powerful engine. We wanted to enhance the power low in the rpm range. In addition, we knew it would be compatible with the factory fuel injection system. This camshaft would also respond well to an exhaust upgrade if we decided to do so in the future.

Sliding a new camshaft into your engine may seem like a big deal, but it is really easy for any semi-competent weekend off-road enthusiast. However, on a 4.0L engine, the camshaft is positioned in the block and requires removal of the cylinder head, radiator, and several of the front engine accessories. In general, for a first-time installer, a camshaft swap on a 4.0L engine should take the better part of the day with the proper service manual. If you are confused about how to properly install your camshaft, call the COMP Cams tech line.

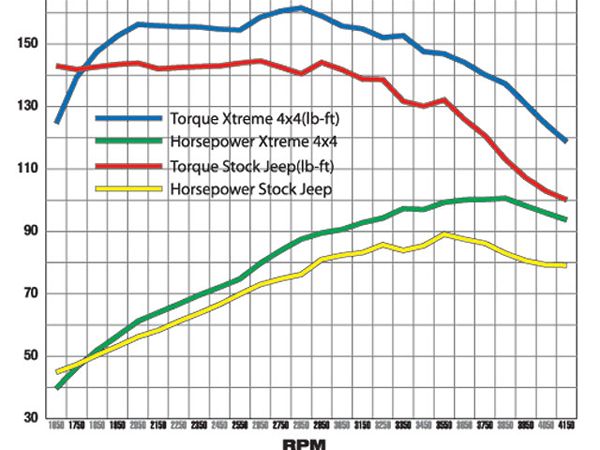

A stop by Westech Performance with our Cherokee netted a fairly weak but not surprising performance. Peak horsepower was a poor 92.8hp at the tire and torque was barely able to reach the 147 lb-ft mark. Next stop was Bitetto Motorsports where Vince Bitetto installed the cam.