Christian Hazel

Brand Manager, Four Wheeler

Christian Hazel

Brand Manager, Four Wheeler

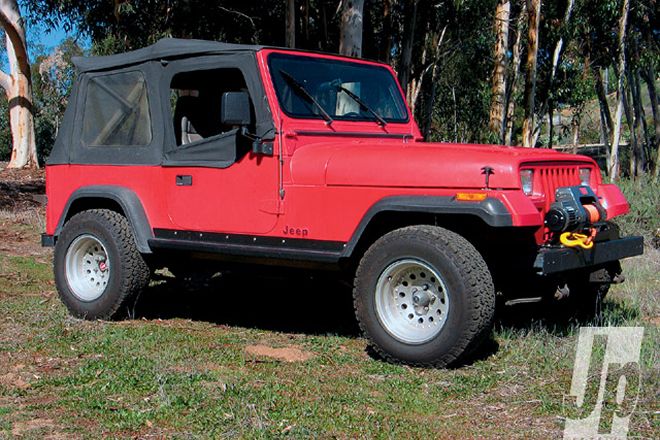

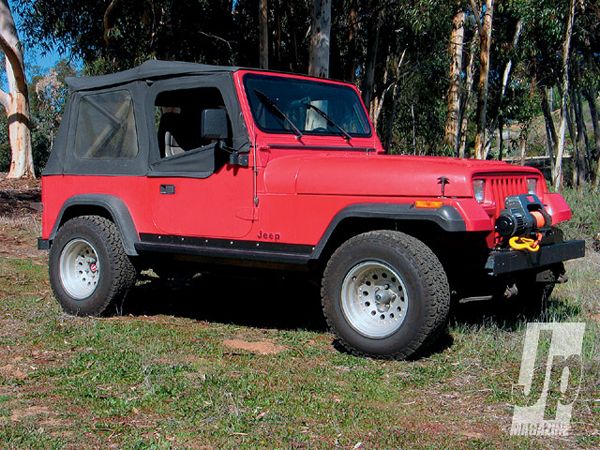

We've been happy wheeling our stock-suspension '89 YJ with two exceptions.

First, the front end really sank once we added almost 90lbs of winch and winch mount to the front. Second, the stock front springs only offered a few inches of uptravel before hitting the bumpstops. That made for some miserable long-distance driving when scooting down miles of unimproved dirt roads to get to our favorite desert wheeling spots.

So, unlike most Jeep owners, when we started eyeballing new suspension systems for our little YJ, our main goal wasn't to fit bigger tires. We were after an improved off-road ride, more wheel travel, and increased load-carrying capacity. We've always considered the Rubicon Express Extreme-Duty systems to be among the finest mass-produced suspensions for a leaf-sprung Jeep. So, we dutifully ordered up the company's 2.5-inch Extreme-Duty Suspension System for our YJ, only to be told, "uh, that's cool guys, but we don't make those springs anymore." Us: "But you make 'em in the 4.5-inch version." Them: "Yeah, but we sell a lot of those. We still have the Standard-Duty 2.5-inch lift springs." Us: "What's the difference?" Them: "Well, after a couple years of hard trail use you may notice some settling." Us: "Is that all? Send 'em."

In the end, we ordered Rubicon's PN RE5530 Extreme-Duty 2.5-inch YJ suspension with four substituted PN 1430 Standard-Duty 2.5-inch lift springs, four of its PN 2050 spring-under U-bolt plates, and the company's PN RXJ505 front and PN RXJ506 rear monotube shocks. At present, we've only done some light wheeling and a couple hundred street miles on the new suspension, but we'll be flogging this sucker in the coming months. Check out some install highlights this time and tune in for some more in-depth driving impressions next month.

By the Numbers

We thought to break out the tape measurer to see how much lift the new Rubicon Express springs netted us from the bottom of the front and rear bumpers to the ground. After a couple hundred driving miles and a few twisty off-road trails, we took our after numbers. Keep in mind our '89 YJ is a bantam-weight, with a four-cylinder engine, no carpet or extras, and only a 15-gallon fuel tank. Heavier vehicles will realize less lift height.