The new fullsize Toyota Tundra with its 5.7L V-8 serves as a solid platform for whatever a pickup truck owner's needs may be. Sporting plenty of oomph to smoke almost any four-wheel-drive pickup off the line, the Tundra simply gets with the program. As such, the rig begs for larger tires. That's why Pro Comp Suspension jumped right on the development of a 6-inch lift kit for the new platform. In the end, Pro Comp would be first to market with two well-thought-out kits-one featuring a simple coilover spacer and the other basically the same kit except with a smooth-riding set of adjustable Pro Comp coilover shocks. We happened to be present the day Dustin Chernoh of DC Customs in Ukiah, California, had his crew begin installing said kit(s) on a local Toyota dealer's truck to see how they compared.

Never one to miss a good opportunity to get the scoop on a new product, we stuck around and watched as the additional 6 inches of clearance took form. Once completed, we took the truck out for a testdrive and even kept in touch with the truck's owner to see how it worked out for him. The results were right in line with what we expected-everything met our expectations, and the truck's owner absolutely loves the new ride. Check out the highlights from the install.

6. Here you can see the beginning of the cutting portion of the installation. The Toyota Tundra has a steel crossmember that ties each framerail into one another under the engine. This member must be removed precisely as instructed by Pro Comp. Removing this section allows the front driveshaft to work with the new location of the front differential assembly. This is arguably the hardest part of the installation process. The instructions show very clearly where to cut the member on each side. However, watching the process made us nervous thinking about cutting up a brand-new truck. No pain, no gain, as they say.

PhotosView Slideshow

Which Kit Should You Buy?

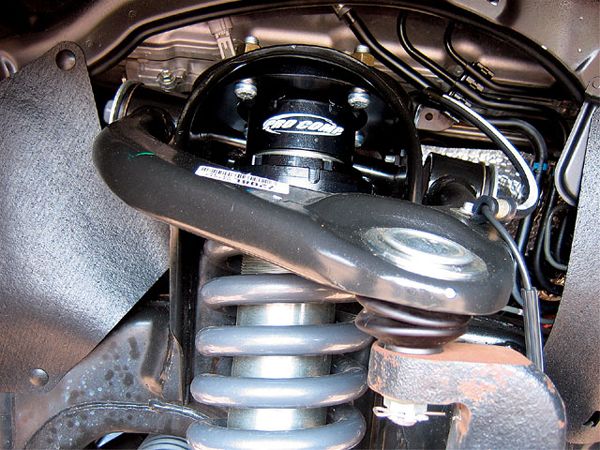

When it comes to performance, the Stage 2 kit is the hands-down winner. However, that gain in function comes with a larger price tag. We think the added ride comfort afforded by the Pro Comp coilover shocks makes it worth the extra money, but if you like the factory ride and simply want to fit a 35-inch tire (or you fear taking your new Tundra off the beaten path), you may want to stick with the Stage 1 spacer version. Here you can see the difference between the two front coilover arrangements.

The Stage 2 kit simplifies installation a little bit because you don't have to deal with removing the factory coil springs from the OE strut assemblies, though the increased bulk of the aluminum-bodied coilovers require additional trimming in some areas of the lower A-arm assemblies. So we think the difference in install effort is negated when everything is said and done. The best part of the Pro Comp Tundra system is the fact that you can always go with the Stage 1 kit right off the bat and then upgrade to the Stage 2 kit as desired.