Ali Mansour

Brand Manager, 4WD & Sport Utility

Photographers:

Fred WilliamsCourtesy of the Manufacturer

Ali Mansour

Brand Manager, 4WD & Sport Utility

Photographers:

Fred WilliamsCourtesy of the Manufacturer

The constant velocity (CV) joint has gotten a bad rap over the years. Most often it's the same tired story about a torn CV boot or shaft failing under the mildest off-road conditions. So why, then, are aftermarket CV joints appearing under more rigs than ever before? What's the big advantage of them over a good old-fashioned U-joint?

To take a closer look at the technology in these new-age CV joints, we turned to the aftermarket CV specialist at RCV Performance. Known for its beefy and race-proven CV joints, RCV also offers a full line of heavy-duty direct replacement CV axleshaft sets for everything from modern IFS GM trucks to the classic 21/2-ton Rockwell axle.

Beneath RCV's heavy-duty CV boot sit a massive billet steel bell, a hardened metal inner race, and a ball bearing cage. Once the shafts are fitted from either side, massive ball bearings allow the joint to pivot and cycle.

Beneath RCV's heavy-duty CV boot sit a massive billet steel bell, a hardened metal inner race, and a ball bearing cage. Once the shafts are fitted from either side, massive ball bearings allow the joint to pivot and cycle.

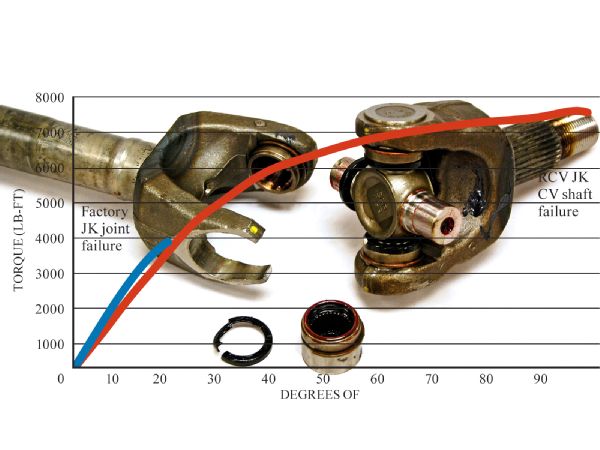

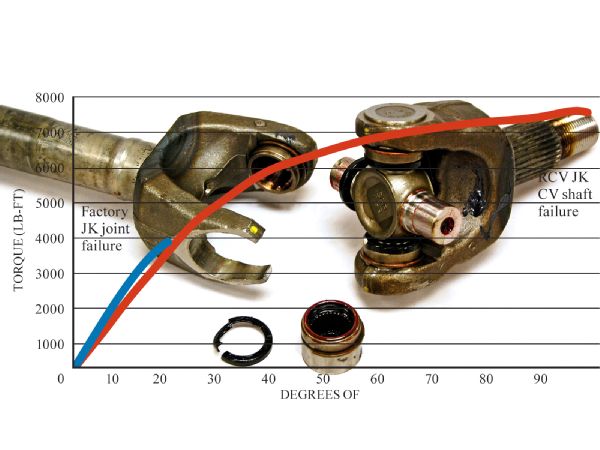

While the strength of a U-joint axleshaft is comparable to that of a CV shaft when the two are at 0 degrees (straight), once the joints begin to change degree angles (bend) the U-joint shaft decreases in strength while the CV remains constant. As the U-joint pivots, the wheel speed fluctuates and will often induce a whipping or binding action. This is usually felt in the steering wheel when the front locker is engaged and the wheels are turned. This is the U-joint's weakest position and where the CV joint shines.

Since the CV is a spherical design it can cycle more easily and allow the shaft to rotate at the same speed no matter what the angle, hence the "constant velocity" name. This means less vibration, bind, and friction, which equates to less breakage and a stronger and more reliable axleshaft. Though the factory IFS CV shafts are a far cry from a beefy RCV setup, they do share similar technology. And if you're unsure about taking the leap of faith toward the CV world, RCV has made it a little easier with their "you break it, we replace it" warranty policy.

So does this mean U-joints will become a thing of the past? Only time will tell, but it's clear that the future of off-road performance is changing velocity in a big way.

Constant Strength

To test the strength of their constant velocity axleshaft kit, RCV pitted its replacement JK Dana 44 axle set against the factory Jeep Wrangler JK U-joint shafts. With both axles placed in an axle testing jig and positioned at 40 degrees, it only took 3,872 lb-ft for the U-joint to fail. By comparison, the RCV joint never failed; rather, the shaft snapped at 7,604 lb-ft. For those of you curious, that's close to the axleshaft strength of a 35-spline Dana 60 axle.

PhotosView Slideshow

PhotosView Slideshow

PhotosView Slideshow

PhotosView Slideshow