Craig Perronne

Brand Manager, Dirt Sports & Off Road

Photographers:

Manufacturers

Craig Perronne

Brand Manager, Dirt Sports & Off Road

Photographers:

Manufacturers

Nowadays it seems as though all you hear about are Dana 60s and 70s, and even 2 1/2-ton Rockwell axles. Yes, these axles are great, and of course we would all love to run these stout pieces in our trail rigs. But have you ever looked into the cost of a custom-made front Dana 60? Not exactly inexpensive, are they? And even junkyard units are getting pricier as they get harder to find.

So if you now have a Dana 44 under your rig and don't have a sufficiently fat wallet to upgrade to a Dana 60, are you out of luck? Four Wheeler's answer is, no, you're not.

It used to be that the Dana 44 was considered to be a fairly stout axle. But as trails got tougher and tires got larger, the 44 got dumped in favor of even stronger hardware. But the Dana 44 is a pretty stout piece, and many companies offer parts to make your 44 even stronger than it now is. So before you retire your Dana 44, seriously consider the following parts and tips that can help it to live a strong and happy life.

Build It To Break?

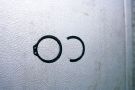

We all have heard of the weakest link. No, we aren't talking about some game show where a homely woman with bad hair and a funny accent berates contestants for not knowing the right answer to some dumb question. A weak link is a part that is built to break before anything else. Warn takes this idea and applies it to the Dana 44 in the form of the hub fuse. It goes into your hub and is built to break before an axle or a U-joint. The idea is that it is a lot easier to replace the fuse in the hub than pull a whole axle out. While a good idea, the drawback is that it cannot be used with Detroit Lockers.

Know Your Limits

We often get asked how big a tire a Dana 44 can hold up to. That's not an easy question to answer. Several factors, such as terrain, vehicle weight, driving style, and engine output, come into play. However, as a very general rule, a 36-inch tire is about the limit for a Dana 44.

Of course, we all know the guy that runs 40-inch tires on his Dana 44 and never breaks a thing. And then there is the guy that breaks everything with 33-inch tires. That's why our 36-inch tire limit is not set in stone. If you drive like somebody with serious anger-management issues in a heavy trail rig with 500 horsepower, you might break parts with tires smaller than 36 inches. But if you drive like a grandma in a lightweight rig with a stock powerplant, you might be able to run a tire bigger than 36 inches.

Terrain also is important here. Rockcrawling tends to be very hard on axles because most crawlers run ultra-low gearing and traction is usually a constant. Terrain where there is slippage, such as mud and sand, tends to be easier on axles. However, mudders usually run lots of horsepower and mud can add a lot of weight to a wheel-and-tire combo. When combined, these can snap an axle like a twig.

Drive To Survive

Besides upgrading your axle, there are some steps you can take to help make your Dana 44 survive while you are out on the trail:

* Don't shock your axle. A lot of breakage occurs when the load on an axle suddenly spikes. This can happen when a vehicle starts to hop on rocky terrain and the driver stays on the throttle. It can also occur from a dead stop when a driver tries to throttle his way out of a situation. Another killer is when a vehicle transitions from a surface with a lot of slippage (such as mud or sand) to a surface with a lot of traction (such as rock). The axle can't keep up with the load on it when going from zero traction to full traction and will break.

* Baby it. To make your Dana 44 survive you need to show it some love. As the above tip suggests, when you shock your axle it can break. When your rig starts to hop, get off the gas instead of staying on it. Roll into the throttle instead of mashing it to the floor suddenly. If you drive a manual, be leery of suddenly dropping the clutch with lots of rpm. While driving with a ton of throttle seems more manly, it also leads to more busted parts and thus to empty wallets.

* Watch the turns. When turning at full lock, the U-joints are at their most vulnerable. This is because the axles place the most leverage on them in this situation. Be especially careful when you have your rig's steering cranked full left or full right.

* Avoid magazine photographers. If you are on the trail and spot a magazine photographer, be careful. These guys are vultures. Usually they hang around in areas that can do the most damage to your rig. Proceed with caution, do not obey the commands they bark, such as, "Gas it!" Also, do not feed them. If you do, you'll never get rid of them.