Alan Huber

Art Director

Alan Huber

Art Director

Taller, heavier tires, a higher center-of-gravity, and softer springs on a modified Jeep conspire to reduce braking effectiveness. Sometimes the problem is severe enough on extreme rigs to warrant high-dollar racing parts and a custom braking system. That's all fine and dandy, but to get better braking without completely melting your credit card try upgrading to some high-performance pads and rotors from EBC Brakes. EBC pad friction material comes in several levels starting with the low-dust, extended-life replacement Ultimax pads. Stepping up the stopping power next are the Redstuff and Greenstuff (6000 and 7000) series. EBC's grip flagship is the high-friction, aramid fiber Yellowstuff pad which gives ultimate brake performance.

EBC rotors come as the plain UPR replacement, the slotted-yet-quiet USR, and the high-performance slotted-and-dimple-drilled GD series. Since EBC does not cross-drill its rotors completely through, there is a reduced chance of cracking around the holes or the holes filling with mud or other trail debris.

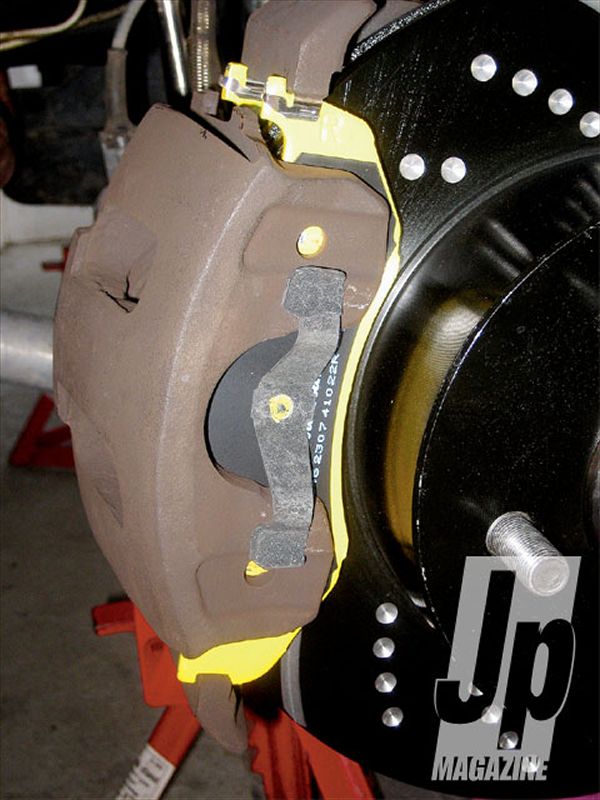

Our '94 Grand Cherokee's pads were just about down to the rivets, and with almost 150,000 miles on the original rotors, we decided a basic upgrade using EBCs' GD906 rotors and DP41022R Yellowstuff pads was needed to restore (and improve!) positive stopping power. Properly working brakes are essential to safety, and although they may seem relatively simple, modern brake systems can chatter, squeal, and generally be a nuisance if parts are installed haphazardly. Please have a professional technician handle brake upgrades if you don't feel confident making them yourself.

We didn't show it 'cause you should know it: Always use your noggin when jacking up a vehicle and use properly positioned jackstands before working underneath. Once the wheel has been removed, grab a 13mm socket to remove the caliper bolts. We're working on a '94 Grand Cherokee ZJ, but coil-sprung Cherokee XJs and Wrangler TJs will be virtually identical. Once the bolts are out, the caliper should slide free of its bracket with nothing more than a little persuasion. Once the caliper is loose, don't let it hang by its brake hose! Set it on a box or hang it from a piece of coat hanger wire.

The caliper piston will need to be retracted into its bore in order to fit the new EBC brake pads. Remember, the old pads have worn away to almost nothing and the sliding caliper and piston automatically adjust to take up the slack created by the thinning pads. Our favorite way to retract the piston is to use an old, cheapie two-slot puller and one of the old brake pads. Reverse and place the old pad against the piston and use the puller under the opposite side of the caliper as a "mini press." Using a wrench, tighten the puller's center bolt to easily compress the piston back into its bore. Don't have a cheapie puller-turned-mini-press? You can also make use of a medium-sized C-clamp positioned on the reversed old pad and the backside of the caliper.

Get the new EBC pads ready for installation by transferring any necessary hardware from the old pads. These small metal clips help to reduce vibration (and therefore squeal) by taking up slack between the pads and the bracket rail they slide on. Yes, your brakes will work OK without the clips if you've lost them, but you'll find the brakes squeal more and that can get annoying...to everyone! Buying a brake hardware kit from an auto parts store will usually get you some replacement clips. Another trick to fighting brake squeal is to smear a thin coat of high-temperature grease or anti-seize compound on the back of each new pad. Don't go crazy and glob it on, though, or it will find its way onto your rotors. A little dab'll do ya.

When deciding whether or not to replace your disk brake rotors, there are a few areas to inspect. First, the surface of the rotor should be smooth without any deep grooves. Old rotors can be machined smooth with a nice crosshatched finish if there is enough thickness to allow it (check thickness with a caliper or micrometer). Our rotors with 150,000 miles on them were at the minimum thickness specified (0.89-inch) in the service manual. This thinness had allowed them to warp slightly, causing a pulsating feel through the brake pedal. Another item to note is the rotor's lateral runout (or rotor wobble). Runout must be measured using a dial indicator on a magnetic stand and usually needs to be less than 0.005 of an inch. Runout doesn't usually pose a problem, but it's important to check it when running new precision rotors so that they wear properly. Be sure to always use new pads with new rotors and replace brakes in pairs!

After you slide on the new EBC rotor, snug it down with an extra lug nut to help hold it in place while you swing the caliper back into place. Again use a little...a very little...dab of grease on each of the caliper bolts to help the caliper slide as the pads wear down. It also helps to add a thin coat of grease to the caliper bracket rails that the pads slide on (arrows). Any place where parts are sliding or moving is a good place for a touch of grease and will help keep brake squeal to a minimum. Just be sure to keep grease and dirty hands from contacting the rotors or friction material on the brake pads. Keeping a can of brake cleaner handy (and using it) is a good idea.

The EBC rotors come with a black anti-corrosion coating, as you saw in the previous photo. This shot shows how the pads remove the coating after a few stops, leaving coating on the remainder of the rotors to keep them from rusting. The area of the rotor where the pads make contact will be kept free of rust with each and every stop. You may notice some noise or a bit of chatter with the new brakes for several stops as the coating is scuffed away. To help your new pads and rotors work better together (or "bed in"), EBC suggests trying to use the brakes with a firm-yet-even pedal pressure for the first 500 miles, staying away from panic or slam-on-the-brakes stops. Of course, be sure to react appropriately to whatever driving scenario presents itself!