It's a common affliction. Around town, your car runs fine and can fry the tires at will, but at highway cruising speeds above 65 mph, you feel a slight vibration in the seat of your pants and through the floor into your shoes. It's not a constant vibration. It's an annoying wave that crescendos, minimizes, then returns. You ask your car-guy friends and one of them claims it's probably a driveshaft vibration: "Just have your driveshaft balanced and it will go away." You decide to do some research first, and that's when you run across the free Tremec Driveline Angle Finder app. This is a very cool app that works in conjunction with the digital level that's in all smartphones. The app shows you how to measure three angles, it compares them, and performs the math to let you know if your car's driveline is properly oriented.

We decided to test this new app on our track-day 1965 Chevrolet Chevelle. We began by setting the car up on the hoist, as it would be sitting on level ground. A drive-on hoist is best for this test, but our hoist lifts the frame so we shimmed the lift points until the car was level and disconnected the rear coilover shocks and raised the rearend until it was at ride height. Tremec's app immediately revealed issues. It informed us that the engine was at nearly a 5-degree down angle at the rear. This isn't necessarily bad, but a more acceptable number would be around 2.5 to 3 degrees tail down. It appeared something had moved.

Many years ago, we modified the stock transmission crossmember to allow us to tuck the Borla stainless steel exhaust system up closer to the floor. Over the years, the crossmember sagged, lowering the trans. Even adding ¾ inch of spacers wasn't enough to bring the rear of the engine and trans up to a less acute angle. Clearly, it was time for a new crossmember. We couldn't replace it with a stock one because the exhaust would interfere, so we looked up American Powertrain's website and found a custom crossmember that would do the trick. With it installed, we rechecked the angles and the app indicated a green light to our modification.

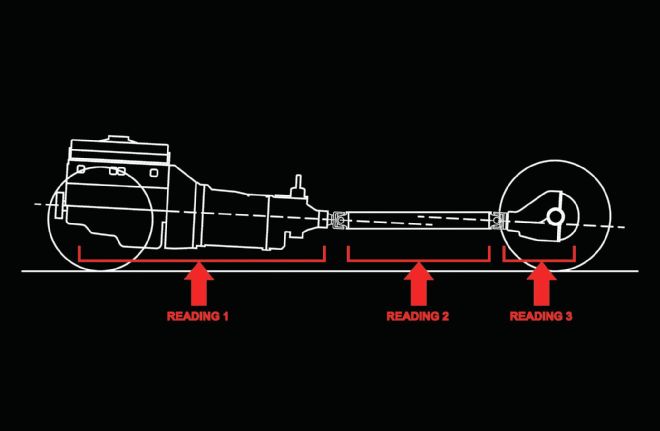

Once the Tremec Driveline Angle Finder app is loaded in your smartphone, just place it on each of the three major driveline components to measure their angles and the app does the rest.

After starting the app, an illustration gives you a visual representation of what you are measuring. An acceptable configuration of the driveline components would be for the engine and trans to be 1 to 2 degrees tail down and the pinion angle to be 1 degree nose up. This will place the two major components roughly parallel yet with a slight angle to both U-joints.

The app recognizes if the phone is vertical or horizontal and automatically compensates. Be sure to measure using machined surfaces like the end of the transmission output shaft or an oil-filter mounting pad. We chose the mounting surface of the bellhousing. As you can see, the phone displays a 4.8-degree angle, which is a bit steep.

The second step is to record the angle of the driveshaft. Our recorded angle was only 0.1 degree.

With the rearend at ride height (supported by a trans jack), we used the machined rear cover surface to reference the pinion angle. Tovey says that if you have trouble finding a location, he has placed his phone across two cover bolts. In our Chevelle, the pinion angle was in the nose-down direction, creating opposing angles, which is not good. The app displays the results in red, indicating the driveline angles are out of spec. Clearly, we had to make some changes.

There's much more to curing driveline vibration than just these three angles. This app only deals with the angles as viewed from the side, but the driveshaft may be angled incorrectly as viewed from the top. Combining these two measurements is called the compound angle. Generally, if the drivetrain uses factory-style components, compound angles won't be a problem, but this may be an issue in applications with custom mounts. If you want to measure your driveline angles but don't have a smartphone, don't stress. You can measure these same angles with an analog tool. Either way, the angle created by the engine and trans should be roughly parallel (within 1 degree) to the pinion angle. In most cases, the engine and trans are slightly tail down, requiring the pinion to be oriented nose up. If the engine and trans are 2 degrees tail down, the pinion should measure between 1 and 3 degrees nose up, placing the angles of the two components roughly parallel.

The results display the U-joint operating angles, not the actual angles that you measured. For example, on the results screen, angle 1 is really the difference between the engine/trans angle and the angle of the driveshaft. Angle 2 is the difference between the pinion angle and the driveshaft. That's why the results numbers displayed don't duplicate what you measured. These results determine if the U-joints are operating at their proper angles. Tremec's Nate Tovey says that U-joint operating angles should not exceed 3 degrees at driveshaft speeds more than 5,000 rpm. If the operating angles are slightly over that, but the driveshaft speed is lower, it's possible to get away with larger numbers. Vibration problems begin when the angles are excessive or if the engine/trans angle and the pinion angle intersect. So it's worth it to test your car, especially if the car is experiencing vibration problems. If your car checks out OK, then congratulate yourself on your accomplishment as a car builder.

The results screen does not display the three readings you just measured. Instead, angle 1 is a calculation of the U-joint operating angle between the transmission and the driveshaft. Angle 2 is the U-joint operating angle between the pinion and the rear U-joint. If either of these angles is out of spec, the results will be red. The final Driveline Operating Angle is angle 2 subtracted from angle 1. The overall angle must not exceed 3 degrees. We had work to do.

We installed a new aluminum crossmember from American Powertrain. This produced a much improved engine angle and still allowed the room necessary for exhaust clearance. The part number is XFGM-10802 and it lists for $380.86 from American Powertrain. It's cool because it is light and fully adjustable.

Installing the crossmember created a much better engine/trans angle. Then we adjusted our Global West upper control arms to create a less severe pinion angle.

If you have trouble finding a reliable way to measure engine angle, you can always remove the driveshaft and use the machined end of the output shaft.

If you don't have a smartphone, that's OK. Harbor Freight and Summit Racing have several inexpensive analog gauges to choose from. Harbor Freight even offers a digital angle finder for less than $30. The procedure is simple: measure the angle of the engine/trans and compare it to the angle of the pinion. They should complement each other by being within 1.0 to 1.5 degrees of parallel. For example, the engine/trans is tail down by 2 degrees and the pinion angle is nose up at 1 degree. The two components are parallel within 1 degree. The driveshaft should exhibit a small angle and not be flat.

Changing pinion angle isn't difficult, but it will require parts. Coil-spring cars like our Chevelle or Fox-body Mustangs will require adjustable upper control arms like these from Hotchkis or Global West. Tapered leaf spring shims are available from Lakewood to adjust pinion angle. End