As automobiles progressed in the late '20s and early '30s, and the country's roads improved, more and more people traveled longer distances for work and pleasure. Being on the road for any length of time in a car of the era with limited luggage space required some creativity. There were a variety of luggage racks that attached to the rear of the car, the running boards, and the roof. Then, in 1936, Mullins Manufacturing produced the Red Cap Utility Trailer.

The Mullins Company was based in Salem, Ohio, where they produced all kinds of metal products. They did stampings for several early auto manufacturers, including Peerless and Franklin, and they also produced the embossed metal ceiling panels found in older buildings. It seems Mullins could and would make anything out of metal-from washing machine tubs to drop tanks for P-51 Mustangs during World War II. The company's attitude seemed to be: If someone will buy it, we'll build it. Unfortunately, there weren't as many buyers for utility trailers as they expected.

Mullins introduced the Red Cap trailer in 1936, it's said the name was taken from the railroad station baggage carriers of the day who wore red caps as identification. The stamped steel bodies featured a tailgate with an opening lid that used '36 Ford hinges and latches. Framerails were stamped channel construction and I-beam axle-mounted hubs with various lug bolt patterns available to match the tow car so one spare would serve both. Weighing a little over 450 pounds, the Mullins utility trailer would haul 1,200 pounds and sold for $119.50.

Red Cap trailers were advertised as the "all season, all-purpose carrier" for luggage, samples, tools, farm produce, building, supplies, hunting and fishing gear, and camping. Mullins claimed the trailer could sleep two, presumably with the tailgate down. While the concept was interesting, the public wasn't all that interested in the Red Cap and after two years and with reported to be close to 3,000, production came to an end.

Mullins trailers were more-or-less forgotten until street rodders rediscovered them in the '70s. Just as they were originally intended to do, these little trailers became popular once more to haul the stuff most street rods don't have room for. Like most things that have come and gone only to come again, the prices for an original Mullins have shot up dramatically as demand has exceeded supply. However, there is an affordable alternative-a fiberglass reproduction from Superior Glass Works.

Well known for their fiberglass Ford, Chevy, and Willys bodies, Superior also has some really unique offerings, such as '37-38 Chevy cabriolet and sedan delivery bodies that fit S-10 frames, an array of 'glass racing bodies, including a '53 Studebaker and a Nova Funny Car, the Superior 54 Sport Wagon, tons of truck parts, and a Mullins trailer (all Superior's products can be seen online).

Superior offers complete Mullins trailer kits that include the body and fenders, with hinged and latched lid, hidden lid release or key lock, '39 Ford taillights (optional are Model A, '32-33 and '42 Ford, '39 and '41 Chevrolet, '50 Pontiac, as well as billet lights). Individual parts such as a frame, box, lid, and fenders, as well as a complete kit can all be purchased separately.

The trailer shown here was assembled at Superior's Molalla, Oregon, facility. If the paintjob looks familiar, it's because Dave at Baham's Auto Body and Paint in Vancouver, Washington, was replicating the flames on the McMullen roadster; Wolf laid down the perfect pinstripes to complete the theme. If you don't have room to put all your junk in the trunk, a Mullins trailer from Superior is the perfect solution, and they look pretty cool, too.

1. If you plan on hitting the road with a street rod and need more space for necessities, or you just need a cool-looking utility trailer, the Mullins from Superior Glass Works is hard to beat.

2. Coming or going, these trailers look great. This one has the optional recess for a license plate. American Classic whitewalls, powdercoated wheels, and '40 Ford hubcaps are from Coker.

3. Baham's Auto Body was responsible for the perfect prep, paintwork, and the flames.

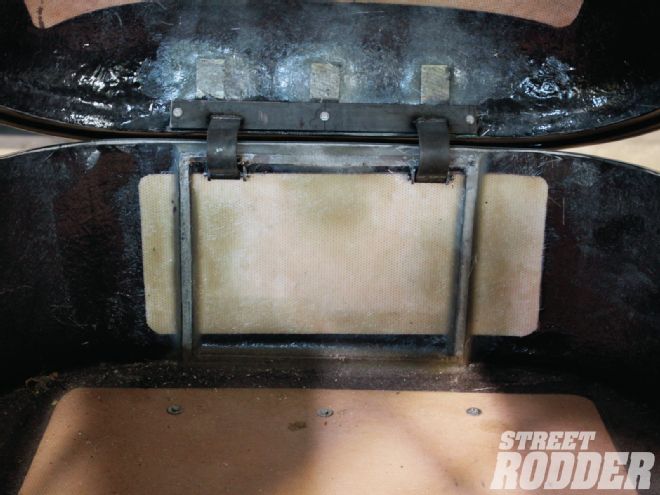

4. Unlike the originals, the lid's hinges are hidden rather than exposed and the rear panel lacks a tailgate and is solid.

5. To secure cargo VersaTie track from Mac's Custom Tie-Downs was installed on the trailer's floor. The spring-loaded tie-down rings can be positioned anywhere along the track.

6. Superior offers a variety of fiberglass bodies, including a '32 Ford Victoria.

7. Superior's parts are hand-laid using 1-1/2-ounce mat. This process has a much higher strength to weight ratio than parts sprayed with a chopper gun.

8. The new fiberglass resins have a shorter cure time than those used in the past. After the resin is applied, rollers are used to eliminate any air bubbles.

9. Anywhere additional strength is needed Coremat is applied over the fiberglass mat-. Coremat adds more bulk to absorb resin, which makes the part stronger.

10. This is the mold for the Mullins' trailer body. Superior's molds are stored inside to prevent the damaging effects of weather and are reinforced to prevent warpage from heat created by the catalyzed fiberglass resin.

11. Once the Coremat is coated with resin, another layer of fiberglass mat is applied.

12. Here the Coremat used in the trailer to reinforce the area around the hinge mounts can be seen. Coremat is also used in the sides of the body and the lid.

13. Superior builds the square-tube trailer chassis in-house; 1-7/8- or 2-inch couplers are offered and a safety chain and integrated trailer stand are included.

14. Trailers are equipped with a dropped axle on leaf springs rated at 2,500 pounds. Hubs are available with early-Ford, late-Ford, and Chevy bolt patterns.

15. This trailer has the standard back panel without the license plate recess and it has Mullins-style fenders.

16. Superior's head honcho, Brad Peterson, holds an optional '39 Chevy taillight in place; the fender is also Chevy.

17. More options are '32 Ford fenders and taillights.

18. Wolf gives the paint and flames a final buff.

19. Last but not least, Wolf applies the finishing touch with the classic pinstriping.

Tips for Buying Fiberglass Trailers

Ask about the shop's fiberglass construction process. Hand-laid fiberglass is preferable because it produces the highest quality end product. Shops that lay up by hand will apply the fiberglass mat in layers for even thickness and hand-roll between the layers to remove air bubbles that cause weakness. Coremat-thin, fabric-like material-should be added to any large, flat panels to add additional stiffness to the body; for example, the hood, floor, and doors. Be wary of chopper gun application-a process that "shoots" fiberglass string and pressurized resin-which can lead to inconsistent thicknesses and trapped air pockets.

Learn how the manufacturer cures and stores their fiberglass parts and bodies. Modern materials used in today's street rods require minimal curing time. It is no longer necessary to leave the body in the sun or to scuff it. By the time you complete assembly of your trailer and it's ready for paint, the 'glass will be cured. The longer the parts are in the mold, the better they will take and keep the shape of the mold.

Trailer Dimensions: 9 feet by 64-68 inches (depends on fender) by 40 inches

Inside dimensions: 46 by 64 by 26 inches (at tallest point)

Outside dimensions: 9 feet by 64-68 inches (depends on fender) by 40 inches

Height at coupler with 28-inch tires: 14 inches

Empty weight: 300 pounds

Capacity: 800 pounds (although the axles and all hardware are rated at 2,500 pounds)