I was walking the aisles of the recent Performance Racing Industry trade show when I came across a booth featuring custom-molded ear plugs. I'm not really sure why they caught my eye, because, to be honest, I've never worn ear plugs. In fact, I never even gave hearing protection a second thought. When I race it has always been pull the helmet on and go. Ear plugs? Those were for the NASCAR guys.

Even race cars like Midgets—especially these running at the Ft. Wayne Rumble—can give your ears a real workout. Ear plugs are recommended.

Even race cars like Midgets—especially these running at the Ft. Wayne Rumble—can give your ears a real workout. Ear plugs are recommended.

However, since Editor Rob Fisher gave me the specific assignment of scouring the PRI show to find a safety item that was unique and one that I, as a driver, had never used before, I was on the lookout for something different. It turned out that earplugs were that something different, at least for me.

As I mentioned, I never gave hearing protection a thought, but I should have and so should you. As racers, we are constantly exposing our ears to very loud and very damaging sound waves. Have you ever talked with any of the older racers around your home track? Have you ever noticed that they often ask you to repeat words or turn their heads so that you can talk into their “good” ears? I know I have, and I bet you have too.

It's important for us to take care of our hearing so that we can not only perform on the track, but live a full life off of it as well. I was about to find out that good hearing protection is quick and easy to get, thanks to the guys at Fit-Ear.

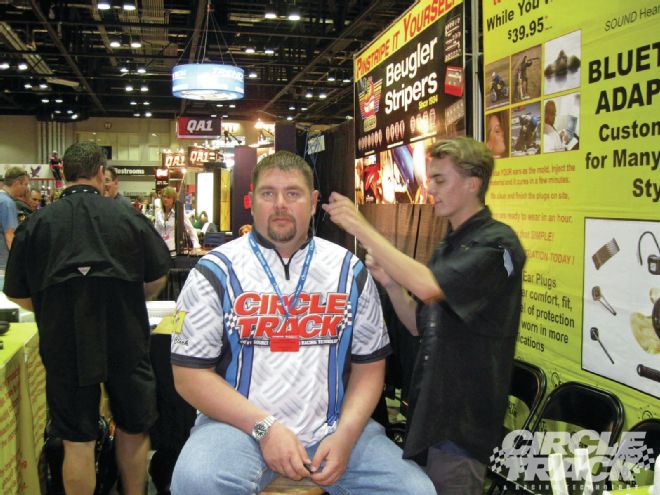

Mark Hood of Fit-Ear prepares the Oto-Block that will go into the ear first. The Oto-Block prevents the ear plug material from migrating too far into the ear canal.

Mark Hood of Fit-Ear prepares the Oto-Block that will go into the ear first. The Oto-Block prevents the ear plug material from migrating too far into the ear canal.

Who They Are

Fit-Ear is a custom ear plug manufacturer that has perfected a technique that allows the company to manufacture ear plugs tailored specifically to your ear in about an hour. Traditionally, Fit-Ear makes ear molds for people at trade shows and events all around the world.

How It Works

I sit down in a chair right in the Fit-Ear booth to begin the mold-making process. The first thing that happens is that Mark Hood of Fit-Ear performs what he calls a pre-inspection of my ear. He uses something called an otoscope or Oto-Light. It's basically a long tube with a light on the end that helps Mark verify that the conditions of the ear are such that an impression can be made.

Mark gives my ear a stamp of approval and the process begins with him placing an Oto-Block into the ear. An Oto-Block is a string with a cork-like plug tied onto one end. This block will prevent the impression material from going too far into the ear canal. It also provides a seal or rather a stopgap for the material to create the end of the finished ear plug.

Once the Oto-Block is in place, Mark had me stick a Bite-Block into my mouth. Aside from the obvious jokes or comments from people who would like to see that Bite-Block permanently attached to my teeth, it actually has a real purpose. This device aligns the jaw and minimizes movement of the jaw while Mark makes the impression of my ear. Move your jaw from side to side and you can actually feel your ear canal move around. If that happens while Mark is making the impression, your custom-made ear plugs won't fit properly and, in turn, won't be as effective. The Bite-Block prevents that movement ensuring that the finished product remains sealed all the way around the ear—even when chewing gum or talking to the crew on the radio.

Mark threads the block into my ear.

Mark threads the block into my ear.

With the Oto-Block and Bite-Block in place, Mark injects a rubbery impression material into my ear canal and outer ear to make a whole ear impression. Obviously, they take impressions of both ears. Fortunately, these guys are nice enough to keep that impression material at room temperature. I have to say that it was one strange sensation to have that blue goo piped into my ear. It didn't hurt, nor was it uncomfortable, but it was weird. The impression will be used to manufacture the actual ear plugs.

After about two minutes, the material is cured and can be removed from my ear, leaving no residue. At that point I get to chuck the Bite-Block into the trash can and the finishing process can begin.

The molding material comes in a tube that looks like a small caulking gun.

The molding material comes in a tube that looks like a small caulking gun.

Mark also manufactures a version of these ear plugs (PN MOS-R1) with a single transducer (mono) electronic packet with 24-inch mono cable. If you want to go for the radio version the only difference in the process is that prior to injecting the impression material into your ear, Mark will place the electronic packet in your ear. He also uses a different kind of material that is compatible with electronics, called Fit-Mold Premium. That material takes five minutes to cure and then it's finished, all in about an hour.

The product design allows under-helmet use for race applications and quite frankly works so well that you can hardly tell you've got them in there with your helmet on. Now the best part—these ear plugs provide noise reduction down to a decibel range of 27-32 dba. Considering that most race cars can produce noise well beyond 95 dba, ear plugs that bring the ambient noise down to the sub-30 dba level are priceless for saving your hearing.

These plugs retail for $185 and come with a 90-day warranty. At that price they're a can't miss addition to your safety equipment for this year's racing season.