Henry Ford's method of locating the beam front axles in his early cars consisted of a triangulated arrangement comprising the wishbone and a beam axle, with a transverse leaf spring. The spring was mounted above the axle on pre-'35 cars and in front on '36-48 models, when the I-beam gave way to independent front suspension. The whole arrangement would pivot about the ball at the rear of the wishbone and the center of the leaf spring, mounted to the front crossmember. It was crude yet offered a huge range of suspension travel, especially when combined with a similar system at the rear.

However, with the installation of non-stock motors and the advent of dropped axles, interference problems with oil pans, or the removal of the wishbone's rear mount-whether on the crossmember or the trans, a la Model A-meant an alternative was required. The hot rodder's solution was simple: Split the wishbone and mount the rear ends of the now two separate halves to the chassis 'rails. Of course, little consideration was given back in the day to bumpsteer, Ackermann angle, or suchlike, and the split wishbone worked on hot rods with limited suspension travel, pretty much defining the look of postwar hot rods.

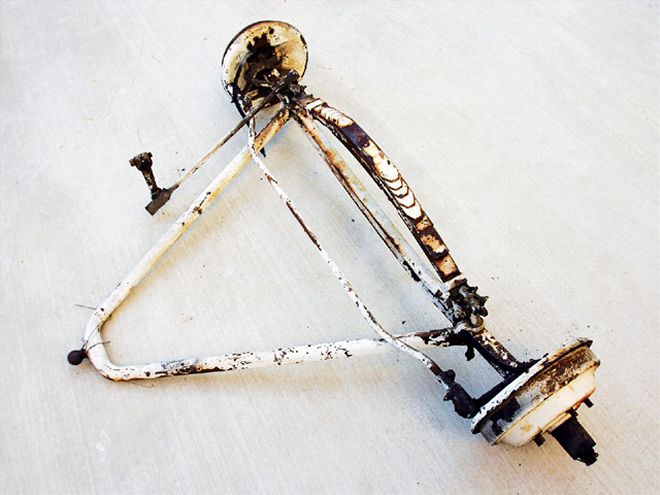

This is a Model A wishbone and a complete frontend. It's way shorter than all the later 'bones at 39 inches, ball-to-perch centers, but uses the same wall thickness tubing. The mounts at the axle end are thinner but are forged and can be gusseted if required.

This is a Model A wishbone and a complete frontend. It's way shorter than all the later 'bones at 39 inches, ball-to-perch centers, but uses the same wall thickness tubing. The mounts at the axle end are thinner but are forged and can be gusseted if required.

We dealt with early axles in the August issue, and touched on wishbones then, but the simple fact is if you want to run an unsplit wishbone, you'll need to source one from the same-year car as the axle. This is because the distance between the spring perch bosses on early Ford axles varies, and hence so does the measurement across the front of a wishbone. The '28-31 Model A axles measure 36 1/4 inches between bosses; '32-36 axles measure 36 1/21/2 inches; '37-41 axles are 38 1/21/2 inches; and '42-48 versions are the widest at 40 3/43/4 inches. Even if you intend to split your 'bones, you still need to be careful, as there are two perch-boss sizes. The '32-36 axles and their corresponding wishbones have yokes 2 inches across, while Model A and all the later 'bones measure 2 1/21/4 inches, though it's only a matter of adding a 1/4-inch spacer to run a later wishbone or Model A version on the '32-36 axle.

Then there's the length of the wishbones to consider. The Model A 'bones are short at 39 inches from the center of the ball to the center of the perch hole; '32 'bones are 47 1/21/2 inches; the '33-34 is 45 1/21/2 inches; the '37-41 is 44 1/2 inches; and the '42-48 measures 50 1/2 inches. Bear in mind that those '35-and-later have the spring in front of the axle, the extension for which will need removing if you intend to mount the spring above the axle in your application, and the '42-48 'bones have a step in them just behind the spring perch. Ideally, the pitman arm for the steering should be mounted directly above the rear mount of the split wishbone if you're contemplating a drag link style to eliminate bumpsteer as much as possible, which is why choosing a wishbone as close to the required length as possible is advisable. However, with the limited suspension travel on most hot rods, this isn't as major a concern as might be imagined. Heck, even stock Model As had a drag link roughly half the length of the wishbone.

Using a cutoff saw, grinder, or even a hacksaw if you're a masochist, the wishbone is cut as far back as possible, or at a length you determine. With axles that have the spring above rather than in front, the now-separate 'bones can be moved apart, though this usually requires some heat at the perch, as they can become rusted over the years, and all this stuff is old now!

Using a cutoff saw, grinder, or even a hacksaw if you're a masochist, the wishbone is cut as far back as possible, or at a length you determine. With axles that have the spring above rather than in front, the now-separate 'bones can be moved apart, though this usually requires some heat at the perch, as they can become rusted over the years, and all this stuff is old now!

Splittin' 'Bones

Just how do you go about splitting a wishbone? Using a chop-saw, a grinder with cutoff wheel, or similar, cut through the wishbone as close to the rear mount as possible, or at a length you require, making sure you cut both sides to the same length. Remember, the farther from the rear you cut, the larger the diameter of the tubing will be. This may not appear to matter, but the next step is to weld in a threaded bung to accept a Heim joint, urethane bushing, or to be period correct, a track rod end, and the large-diameter tubing will look odd welded to the bung if the wishbone is cut at some distance from the end.

The next step is to source a mount to attach the new end of the wishbone to the chassis 'rail. You can make your own, which will require a tapered hole if you use track-rod ends (tapered bungs can be sourced to weld into a bracket here) or purchase 'em ready-made from Speedway Motors, Thompson's Garage, and other vendors. If you have a fat-fendered car, Chassis Engineering, Total Cost Involved, and Pete & Jake's sell split-wishbone kits that bolt into the frame and allow the fitment of an automatic transmission, such as a TH350.

New 'Bones

This really is wish-list stuff. How about brand-new wishbones, in either mild steel or stainless steel? Industrial Metal Craft in Las Vegas is manufacturing both, as either a reproduction of an original '32 wishbone with the stock ball joint-but with smaller yoke with a 2-inch inside opening-or as a modified version with a 2-1/41/4-inch opening and a larger front to the tube section to accommodate the unique holes, which allows the tie rods to pass through the wishbone.

The wishbones are also available already split, the steer-through versions of which are direct replacements for SO-CAL Speed Shop hairpins and set with a 7-degree caster, or as original, though they can be supplied for a stock-width axle or a narrower aftermarket axle. The ball joint is investment-cast stainless steel, as are the yokes, while the tubes are either 304 stainless or cold-rolled steel, giving the option of polishing, chrome, or paint. Industrial Metal Craft will even sell the ball joints, stock yokes, or steer-through yokes separately.

New Tricks

Just when you thought you'd seen it all, and there were no new ways to do anything, someone always shakes things up. This time, it's those creative and talented minds at Ionia Hot Rod Shop. Just take a look at how they modify '35-36 wishbones. Ionia's Dennis Lesky admits to loosely copying ideas he gleaned from a '41 Indy car, mounting the rear of the 'bones between the X-member and chassis 'rails, using a section of the original ball joint turned vertically. Of course, this requires a second ball joint from another wishbone, but they've always been discarded up until now. Since Industrial Metal Craft is making new ones, the sky's the limit! They also flip the 'bones upside down for tie-rod clearance, then swiss-cheese 'em for extra cool points. Nice work!