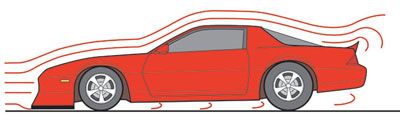

Ever stick your hand out the window at highway speed? Do it palm-first,and the air pushes your whole arm backward. Hold your hand out palm downand you can control arm movement, even against the air pressure. Tiltyour hand upward, and air pressure forces your arm higher. Go theopposite way and tilt downward, and your hand gets pushed downward.You've just experienced the aerodynamic properties of drag, lift, anddownforce. Air flowing over, under, and around a car acts the same way.

Drag and Frontal Area

Palm-first, your hand has lots of resistance. That's why air pressurepushed it back. Engineers call this drag. Measured in pounds, total dragis a combination of the vehicle's frontal area, dynamic pressure (airdensity and velocity), and a shape factor that defines how slippery itis. The shape factor is a dimensionless numerical expression called thecoefficient of drag (Cd). Think of Cd as an efficiency factor, likehorsepower per cubic inch (hp/ci) is for engines: A go-cart engine and asupercharged big-block Chevy might make the same hp/ci (be equallyefficient), but the Rat motor's total power output is vastly greaterbecause it has more displacement. Likewise, the Goodyear blimp and apencil have a similar Cd because they have a similar shape. Thedifference lies in the overall size of the object (also known as frontalarea) that is pushing through the air. In car terms, a Corvette has botha much lower Cd (it's swoopier) and less frontal area (it's smaller)than an 18-wheeler.

Also, aero forces go up with the square of the speed, meaning that ifyou double the vehicle speed, you increase the total drag resistance byfour times. What's worse from a gearhead standpoint, AeroDyn's GaryEaker points out that horsepower requirements to reach a given speed goup with the cube of velocity. At 200 mph it takes eight times as muchpower to push the car through the air as it does at 100 mph. If your carneeds 80 rear-wheel horsepower to run 100 mph, for it to see 200 mphrequires 640 hp. Gives you more respect for those 300-plus-mphBonneville racers, doesn't it? Therefore, if top speed is the goal,anything that reduces frontal area and makes the vehicle's shape morestreamlined is crucial.

Lift and Downforce

Returning to our palm test, your upwardly inclined hand experiencedpositive lift; tilted downward it saw negative lift, or downforce.Nearly all stock cars have natural positive lift. Older cars with bluntfront ends generated lift kind of like your hand did--air getsunderneath and pitches the nose up. Pre-'68 Corvettes, old Cobras, andclassic-era GT-40s were notorious for front-end lift at speed. But evenmodern, fuel-efficient, bubble-cars have lift, paradoxically caused bytheir very efficient wing-like shape.

Positive lift is bad; it makes a car float and hard to control,especially at speeds over 100 mph. It's far better to have downforce topush the car down against the pavement, increasing its traction. "It isimportant to be able to steer the car at the speed you want to run at,"says engineer Chuck Jenckes. "You don't want a buoyant car."Unfortunately, many of the techniques used to increase downforce alsoraise drag. As Jenckes puts it, "You need one to generate the other." Itbecomes a fine juggling act--aero drag reduction from betterstreamlining versus increased drag from more downforce--and which one toemphasize is dependent on the vehicle's inherent design, its intendeduse, and (if engaged in organized racing) the sanctioning body's rulesrestrictions.

More Downforce or Less Drag?

What's more important: going as fast as possible, or being able to turncorners? The answer will dictate whether you want more downforce or lessdrag. For anything that must turn, generating downforce usuallyoutweighs any additional drag that might be generated. "You can make upmore time in the corners than on the straights," says Jenckes.Road-racers always want lots of downforce. With oval-trackers, itdepends on track length, whether the rules permit radical downforcemods, and if the cars are power-limited. Today's Nextel Cup teams payclose attention to streamlining because the rules require apower-limiting restrictor plate and closely limit downforce-generatingmods to those that equalize competition and ensure vehicle safety.Short-track cars benefit from downforce enhancers, especially becausethey are usually traction- limited, not power-limited.

On the other hand, for land speed racing, ultimate straight-line topspeed is the goal, so reducing drag reigns supreme in all cases. Thesecars need only enough downforce to hold traction and to keep the frontend planted. Finally, in drag racing you want to add some downforce fortraction, but the majority of drag-car aero mods are to enhance top-endvehicle stability and improve performance past mid-track and through thetraps. "A drag-car should have no more downforce than needed or you'rewasting your potential," says Racecraft's Mark Wilkenson.

Aero Tricks You Can Use

A multiuse street car must be a jack of all trades: stable at highspeeds, sticky in the corners, versatile enough to survive driveways andgas stations, and tough enough for weekend race duty. Realistically,there are limits to what you can do to an average car without going offthe deep end. Unless you go the route of extremecustomization--chopping, channeling, narrowing, and sectioning--it'shard to significantly improve a production car's drag coefficient. Youcould remove the driprails, molding, chrome trim, and antenna; shave thedoor handles; lose the windshield wipers and side mirrors; racer-tapeall the body seams; meticulously polish the vehicle's surface; close theside windows; lay back the windshield; and block airflow through theradiator grille (to the extent the car doesn't overheat, but quitepractical in a short-duration drag race). These things will lessen draga little bit. However, generating more downforce, even on astreet-driven car, is entirely practical, and some of the things thatadd downforce can also aid aero efficiency.

Spoilers and Air Dams

"The two hotspots where there's the most room for improvement on mostcars are the lower front and upper rear," says AeroDyn's Gary Eaker.Racers realized this as far back as the mid '60s and developed rearspoilers and front air dams to help their cars maintain traction. A rearspoiler is a device attached to the car's upper rear surface (usuallythe trunk lid) with no gap between it and the bodywork. If it has a gap,it's considered a wing, which is far more complex.

As its name implies, a spoiler's purpose is to "spoil" the fast, smooth,low-drag airflow coming off the roof. By sticking up into the airflow, aspoiler causes the airflow to detach and separate, reducing its velocityand creating a pressure rise that decreases the rear lift tendencies.Although a rear spoiler primarily adds downforce, in some situations itcan also decrease drag, depending on the spoiler's height, angle, andlength of extension off the deck. The more vertical the spoiler's angle,the more the downforce at the price of increased drag. Exact resultsvary per vehicle and can only be determined by cut-and-try testing, butsome studies suggest that the most downforce is achieved with a spoilerheight that's about 8 percent of the car's wheelbase. That means about8-9 inches for a 106-inch wheelbase. For any drag decrease, the spoilerheight will usually have to be less than 1 inch, but up to 2 inchesthere is usually no drag penalty.

Air dams vary from simple lower-front-valance slab-like extensions tocomplex cowcatchers. An air dam's purpose is to reduce the amount of airflowing underneath the car, which has a number of benefits. Most cars donot have smooth underbodies--exhaust, drivetrain, and suspension hangdown, creating considerable additional drag. In this situation, a frontair dam can improve aerodynamics even though it increases frontal area.More importantly, a front spoiler reduces air pressure underneath thecar. Any air remaining under the car is turbulent, just like air behindthe rear of a vehicle. That's the principle of drafting in NASCAR; guysget hauled along behind the lead car by riding inside its low-pressurewake. A front air dam creates a similar effect under the vehicle,essentially sucking the car into the ground.

Spoilers and air dams work for most vehicles without complexexperimentation. But for the vehicle to perform properly there must be abalance of forces at the front and back. If too much downforce isapplied to the front, the rear might get light; conversely, too muchrear downforce may result in front-end pitch. Most front-engine,rear-wheel-drive cars with correctly balanced suspensions work best withslightly more downforce at the rear than at the front.

Wings

It stands to reason that if you turn a wing-like shape upside down withthe flat surface on top and the curve on the bottom, it will work theopposite way it does on an airplane--it should generate downforce. Doneright, upside-down, rear-mounted wings can generate huge amounts ofdownforce, but unless the wing is integrated into the vehicle's overallbody-shape (as on classic Dodge Daytonas and Plymouth Superbirds),there's usually a big drag penalty. However, even though a bulky wingmay reduce ultimate top speed, it increases a car's cornering ability somuch that overall lap times are dramatically lowered. The problem isimplementation. There are literally thousands of potential airfoilshapes, and the wing's interaction with the rest of the body isextremely complex. You cannot just take a generic wing, turn it upsidedown, haphazardly mount it, and expect it to work. Yet if the wing trulyis effective, it can seriously unbalance the car, actually unloading thefront tires. At a minimum, a huge cowcatcher-style front spoiler isusually needed to regain balance.

Bearing this in mind, there are several things to consider when planninga wing. Thicker and/or more highly cambered shapes generally generatemore downforce, but also more drag. On any given wing design, mountingthe wing at a lower angle of attack (flatter) has less drag, but is alsonot as effective. A steeper angle (with the rear higher than the front)yields more downforce, but also more drag. Adding a small 90-degreewicker or "Gurney flap" to the rear edge of an existing wing can adddownforce with little drag penalty, and varying height wickers can serveas a fine-tuning aid for different tracks and conditions. Vertical sideplates at each end of the wing keep air from spilling over the sides,sometimes increasing the wing's effectiveness as much as 30 percent.There are also multi-angle and multi-element wings, which are good ifwing size is limited by class rules, as is often the case.

Ground Effects and Diffusers

Even the best air dam can't fully remove the effects of tires, whichcause over 40 percent of an open wheeler's total drag. Even on afendered car, the wheels and tires remain a major lift and drag source.The tires' rolling resistance makes up a component of drag, and thisresistance increases at higher speeds. Air accelerating over the top ofa spinning wheel reduces pressure on its top surface, creating lift.Tires also add to the frontal area, but no one wants to trade off thestickiness of wider tires for more aero-efficient skinny tires--unlessthey're racing Bonneville. But you can run the tires at higher inflationpressures to reduce rolling resistance, enclose them in fenders, and getair out of the fenders as efficiently as possible. If there are no rulesto obey, bulge out the fronts of the fenders, and tuck in the rearsslightly.

As for the car's underbody . . . clean it up! If you can, make a fullbellypan. At a minimum, extend the front air dam horizontally with aflat plate back toward the front axle and oil pan. This tends to reducethe turbulence and accelerate what air that does get by the air dam,lowering its pressure, which increases front downforce. In a perfectworld, nothing would hang lower than the bottom of the framerails. Aflat, full underbody lowers drag, but according to Jenckes won't alteroverall lift tendencies, which are dictated by overall vehicle shape. Inother words, adding a full bellypan neither appreciably helps norhinders downforce--unless you take advantage of the Bernoulli Principle,which says that air speeds go up when air is forced to flow through atube of reduced cross-section. That's how a carburetor's venturi worksand the same principle can be used underneath the car.

So once you've got the floor flat and the car low, add a slightnose-down rake--1-2 degrees is sufficient. This makes the entireunderbody act like a simple venturi: There's now a narrow throat underthe front--which accelerates the air and produces low pressure--and therest of the body acts like a long diffuser, permitting rapid (throughgradually decelerating) air to flow toward the rear. And out back, curvethe under-panel upward to form a duck-tail integrated with the outerrear taillight panel. This helps the rear low-pressure wake suck air outthe back.

Diffusers are a lot more complicated (look at the underside of anIndyCar), and are beyond the scope of this story.

Air can be either your enemy or your friend, and what works on one carwon't necessarily work on another. Drag can limit the car's top-speedpotential, but correctly managed, drag in the form of downforce canproduce tremendous improvements in traction to the point that the entiresuspension must be stiffened and retuned. Many techniques that helpimprove drag and aero are relatively inexpensive if you have access tobasic metalworking equipment and the patience to cut, try, test, andexperiment. And that's the essence of hot rodding.

Case Study: Maximum Motorsports' Wing

Sprinkle drops of motor oil on the top and bottom wing surfaces and thengo run several laps. If the wing is working, the oil drops will runstraight back. They'll puddle or run off at an angle if it's not.

Sprinkle drops of motor oil on the top and bottom wing surfaces and thengo run several laps. If the wing is working, the oil drops will runstraight back. They'll puddle or run off at an angle if it's not.

Balancing the extra downforce from the new wing required asplitter-style front spoiler. The finalized single-element rear wingwill be sold as a 3.5-pound carbon-fiber retail item for '79-and-upMustangs and considerably revised compared to the aluminum prototypeshown here.

Balancing the extra downforce from the new wing required asplitter-style front spoiler. The finalized single-element rear wingwill be sold as a 3.5-pound carbon-fiber retail item for '79-and-upMustangs and considerably revised compared to the aluminum prototypeshown here.

Most of us don't have access to wind tunnels (although AeroDyn is makingit easier-- see www.aerodynwindtunnel.com). The proven alternative is tostick with cut-and-try on-track testing methods. Maximum Motorsports(MM) sells performance Mustang parts and races a '92 Mustang in NASA'sAmerican Iron series as a developmental testbed for its product line.Many competitors in this series bolt on big wings, but few have reallytested them. MM planned to sell the final product to the general public,so the company had to make sure they work. MM started with a generic,store-bought "Johnny Bling" wing marketed to the sport-compact crowd andquickly discovered it didn't do squat. As owner Chuck Schwynoch puts it,"We finally had an aerodynamicist come up with a real wing shape." MMdeveloped the wing through repetitive on-track testing, initially byobserving the behavior of oil droplets on its surface. Later, strips ofyarn were taped to the wing, and a video camera installed on the rearpackage tray recorded their behavior.

Case Study: Teague LSR

Bonneville cars are optimized for straight-line aero, with only enoughdownforce to keep from loosing traction. You won't see any bigdrag-inducing wings, but the old-tech car's overall cross-sectionalprofile has some upside-down, wing-like attributes--note how theunderside is rounded, while the top is flat.

Bonneville cars are optimized for straight-line aero, with only enoughdownforce to keep from loosing traction. You won't see any bigdrag-inducing wings, but the old-tech car's overall cross-sectionalprofile has some upside-down, wing-like attributes--note how theunderside is rounded, while the top is flat.

Teague says you can't get the front narrow enough. In this case, thatwas much more than a mere sheetmetal exercise. The front wheels areactually offset longitudinally to narrow their track, which called forreal creativity in steering and suspension linkages.

Teague says you can't get the front narrow enough. In this case, thatwas much more than a mere sheetmetal exercise. The front wheels areactually offset longitudinally to narrow their track, which called forreal creativity in steering and suspension linkages.

Al Teague's streamliner holds two FIA international records over 400mph. It is the world's fastest ground vehicle with a single-pistonengine and two-wheel drive, hitting an average speed of 425 mph over a1-mile course with a 432-mph peak. The old-school car evolved notthrough fancy wind tunnels or book-learned aeronautical degrees, but viathe basic cut-and-try method. Teague's car began life as a 312-mphopen-wheel Lakester. Enclosing the front wheels, narrowing the track,and partially enclosing the rear raised speeds to 354. Six more years ofdevelopment, fully enclosing the rear, and a better engine got the carover 400. It may not be high tech by today's standards, but it sure doesrun. Believe it or not, the car weighs 4,000 pounds (salt racers useweight for traction and stability).