Take a good look at the seats in your muscle car. If they’re stock, they’re flat as a board, right? That was just the standard shape of seats for decades in America prior to the mid 1980s. That basic shape plus a seatbelt works fine for straight-line blasts, but when we start asking for more grip in the cornering department, those flat seats start becoming an impediment to all the improvements you’ve made.

That’s because no matter how well belted you are, if a seat doesn’t have side bolsters to prevent your hips and shoulders from sliding across the seat surface, you’ll end up fighting to hold yourself in place while simultaneously trying to turn the steering wheel. Think about it this way: not only is your attention split, thereby slowing your reactions, but your arms and body are tensed to hold yourself in the seat and cannot respond as crisply as they could otherwise. Trust us, it’s far better to only give your arms one job, and that’s to direct the car.

…when we start asking for more grip in the cornering department, those flat seats start becoming an impediment to all the improvements…

The TMI Pro-Series low-back bucket seat begins with a brand-new custom tube frame from TMI that’s much stronger and more versatile than anything OEM from the 1960s.

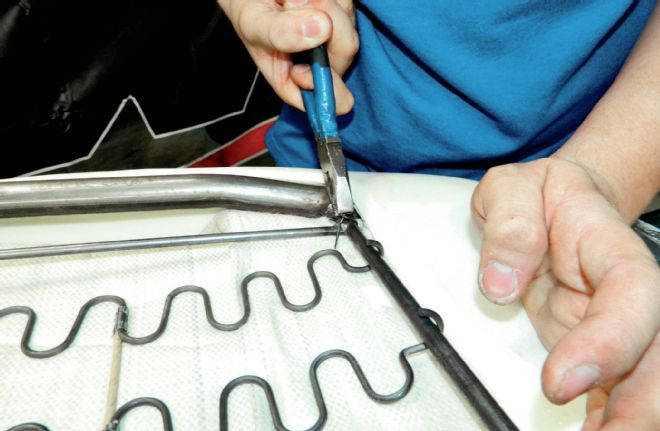

TMI builds each seat by hand and the tools they use are very simple hog ring pliers and hog rings, rods, and diagonal cutters. Also needed are interior trim adhesive and some baling wire.

Here’s a pro upholstery tip: Use a thin plastic bag over the seat foam to ease slipping the upholstery over the new foam.

Baling wire is pulled through the wires molded into the foam and around the frame rods to secure foam to the frame.

…if a seat doesn’t have side bolsters to prevent your hips and shoulders from sliding across the seat surface, you’ll end up fighting…

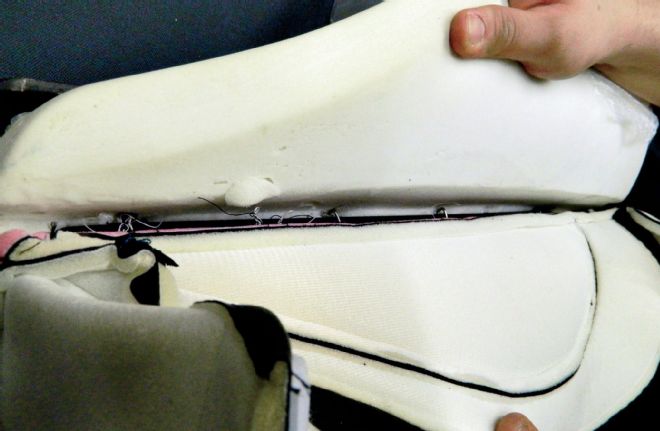

Next, the technician inserts the listing rods into the loops on the inside seams of the upholstery.

Hog rings are pinched into place in several spots to keep the listing rods secured to the molded-in wire in the seat foam.

Space the rings out pretty evenly to make sure there is enough bite to keep everything in place.

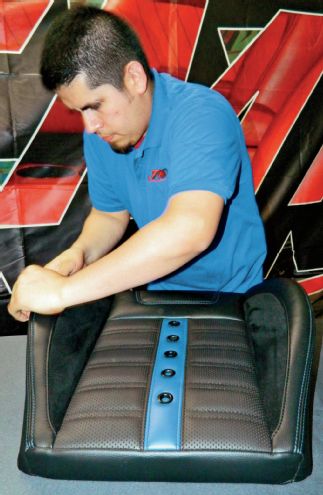

Now it’s time for the good-looking part! With the inserts hog-ringed down, the upholstery is rolled over the edges of the foam, then smoothed and stretched tight as you go.

So now you can see why in the past couple decades seat bolsters have become a given on new cars. We’re actually so used to them now that you probably haven’t noticed that any given modern commuter sedan has more bolstering in the seat than any vintage muscle car ever did. That’s just unacceptable. For some, the option to switch to a modern high-back sport seat fits with the look of their project, but if you really want to maintain that vintage vibe, you have to stick with something that looks more retro. Thankfully, TMI has stepped up to fill in that gap with their Sport, Sport II, Sport R, X, XR, and now Pro Series seats that offer modern, aggressive bolstering on the top and bottom sections for more driver control. Moreover, these still retain a lower-back–style option that look more appropriate in a vintage car.

After long being absent from the Mopar scene, TMI is stepping into our arena with these all-new seats that will be available in both low- and high-back design. To see what goes into crafting a pair from scratch, we visited TMI’s headquarters where they were busy creating the Pro-Series Sport XR Seats for a SEMA debut car: a 1966 Dodge Coronet known as Project Ragnet, owned by American Powertrain. Here’s how they did it.

Thankfully, TMI has stepped up to fill in that gap…

On the backrest upholstery, the technician stretches it around until the zipper seam meets, and he can zip the backrest closed. We love that simplicity.

To secure the bottom edges of the upholstery to the frame, it’s stretched tight and J-clips are slid over each edge and onto the frame rods.

You may need to go back and massage the upholstery over the bolsters a bit to remove wrinkles. Use a touch of steam for this.

With all the upholstery stretched tight, next he bolts the seat track sliders to the bottom of the seat frame.

Next up is the hinge and tilt assembly. This goes together quickly on the bottom side with all supplied hardware.

You may have to fish around a bit to locate the hinge mount hole on the top half, but once you’ve found it, alignment and installation is simple.

Looks great, doesn’t it? The price of a pair of these premium Sport XR seats is quite reasonable at around $1,800 MSRP, front. (Base models start at $1,200.) TMI also offers various sizes of rear seat upholstery in oversized sections to allow a trim shop to cut it to fit the rear seat and panel configurations. Small, medium, and large trim sections will be offered to complete the interior of your car so it matches the TMI Pro-Series seats in the front.