The classrooms are small, but you won't be there long. The class offers about 75 percent hands-on welding time.

The classrooms are small, but you won't be there long. The class offers about 75 percent hands-on welding time.

Most good racers, whether they know it or not, will subscribe to the following saying: "Knowledge isn't always knowing but knowing where to find out." In some cases, it's easy. There are schools for building engines, setting up a chassis, and driving, but what about some of the other important skills?

Lincoln Electric, maker of those familiar red welders, actually offers two Motorsports Welding classes - basic and advanced. Held at its world headquarters in Cleveland, Ohio, these classes are for folks who can already weld. If you've never welded, you'll need to get up to speed before signing on. Sources for the basic education include your local vocational technical school.

Welding chrome-moly tubing starts out easy, and you can make it as difficult as you want. Here, a student takes on a complicated welding position all on his own.

Welding chrome-moly tubing starts out easy, and you can make it as difficult as you want. Here, a student takes on a complicated welding position all on his own.

Once you have the basics, then you can proceed to the Lincoln schools. Each of the class sessions run for five days. There's a great student-teacher ratio because each session is limited to about 12 students. Both offer about 75 percent hands-on welding time.

The differences between the two classes allow you to tailor the class to what you want to learn within the class's agenda. As one example, a student in the basic class worked for a drag team, and his job was to be focused on the repair of blown aluminum heads and blocks. He spent the majority of the school week welding on scrap heads and blocks that had been donated by the many race teams partnered with Lincoln Electric. Another was a racer who ran endurance go-karts. He welded nothing but chrome-moly tubing all week to take advantage of having instructors virtually at his side to get him up to speed.

At Lincoln's advanced welding seminar, race teams from all kinds of motorsports are invited to try new equipment and methods of mostly TIG welding. Here, a crewmember from a pro drag team welds on a scrap aluminum head with a new Lincoln inverter TIG welder.

At Lincoln's advanced welding seminar, race teams from all kinds of motorsports are invited to try new equipment and methods of mostly TIG welding. Here, a crewmember from a pro drag team welds on a scrap aluminum head with a new Lincoln inverter TIG welder.

The basic class is just that. You'll be exposed to MIG, TIG, plasma, and oxyfuel torch cutting, as well as preparing yourself for the advanced class. Many students will take the two classes back to back in order to increase their skills even faster. The basic class serves as the prerequisite for the more demanding advanced class. The Lincoln Motorsports advanced class was developed for racers who needed to know about welding the more high-tech materials that are increasingly used on today's race cars. To that end, the class is 100 percent TIG welding, requiring students to come prepared with a basic knowledge and experience level with TIG before taking the class. The good news is that if you have basic TIG skills, the class will give you the opportunity to add to them. The instructors are the same guys we see at the big races, welding the tough jobs at the track. Since Lincoln is involved in nearly every type of high-level racing, its instructors have seen and done it all. You gain from their experience.

Each phase of the class is clearly demonstrated by the instructors, and questions are answered.

Each phase of the class is clearly demonstrated by the instructors, and questions are answered.

Each day, class time (in both basic and advanced) is limited to an hour or so of material you can actually use on the job. The advanced class concentrates mostly on how to identify and weld more exotic metals. The bonus is the extensive amount of reference material you'll take home. The real pearl in this package is a set of educational materials on the metals and their characteristics-the EMJ Materials and Technical Resource. This is a two-book reference set that every shop should have. Other materials show you how to identify alloys and their welding characteristics, as well as which ones not to weld. Critical filler metal is clearly explained in detailed handouts you take home.

They're right there with you. An instructor watches as a student welds magnesium. He's actually welding two scrap quick-change covers together.

They're right there with you. An instructor watches as a student welds magnesium. He's actually welding two scrap quick-change covers together.

We're going to place emphasis on the advanced class. On the first day, everyone gets up to speed by welding chrome-moly tubing. This aspect reinforces control since welding tubing means simultaneously rotating the torch and moving the filler rod. This gets everyone on a more even keel for TIG welding before they move on to day two and titanium (TI). TI requires 100 percent gas shielding coverage, and that takes some getting used to. A trailing cup keeps the Heat Affected Zone (HAZ) enveloped in shielding gas and protects the area from outside air contamination until the weld cools enough. The TI pieces you weld are also placed in a jig where gas shields the bottom of the piece and the backside of your weld. It takes a few passes to get used to working with all the shielding equipment, but the welding itself is the same as most other TIG operations. There's an elaborate array of telltale colors involved with welding TI that you need to know about before you light up. Since TI is used so much on military equipment, the government has come up with standards for welding TI that can also apply to motorsports. It's more knowledge you'll take back to your shop.

On the third day, things get more high tech with nickel alloys, sometimes commonly referred to as Inconel, a metal used for high-temperature exhaust pieces on race cars. The trick to welding nickel alloys is the keyhole style of welding because the metal is so gummy when wet. We've all seen a hole open up in our weld puddles when we don't move the torch fast enough. That hole is called a keyhole. When you're welding nickel alloys, you actually want that keyhole to develop so you can put your filler rod right into it to fill out the puddle.

Titanium is one of the exotic materials you'll weld in the Lincoln Electric advanced school. The finished weld is shown with the trailing cup attached to the torch. Note the color of the weld's Heat Affected Zone (HAZ). The colors indicate acceptable and unacceptable welds based on a color scale and contamination.

Titanium is one of the exotic materials you'll weld in the Lincoln Electric advanced school. The finished weld is shown with the trailing cup attached to the torch. Note the color of the weld's Heat Affected Zone (HAZ). The colors indicate acceptable and unacceptable welds based on a color scale and contamination.

The fourth day is reserved for magnesium, starting with a graphic demonstration that most will not likely forget. The instructor welds two pieces of aluminum plate together using a magnesium filler rod. Once the weld is finished, it's passed around for all to inspect. Indeed, it looks like the perfect weld with the proverbial "row of dimes" texture. The instructor then raises the piece high over his head and drops it on the metal welding table. Upon impact, the pieces come apart, including that perfect weld bead. As similar as they are, magnesium and aluminum cannot be welded together. The instructor adds a very useful tip about race teams that keep their aluminum and magnesium filler rods on opposite walls of the shop to keep from mixing them. Race teams donate broken magnesium castings to the school so you can learn how to repair them. Welding magnesium is much like welding aluminum, but you'll never forget to double-check your filler rod.

The last day is student's choice in that what you choose to weld is entirely up to you. If you want to revisit any of the four materials, you're welcome. If you have something you brought with you that needs more personalized seat time, the instructors will gladly help you there, too.

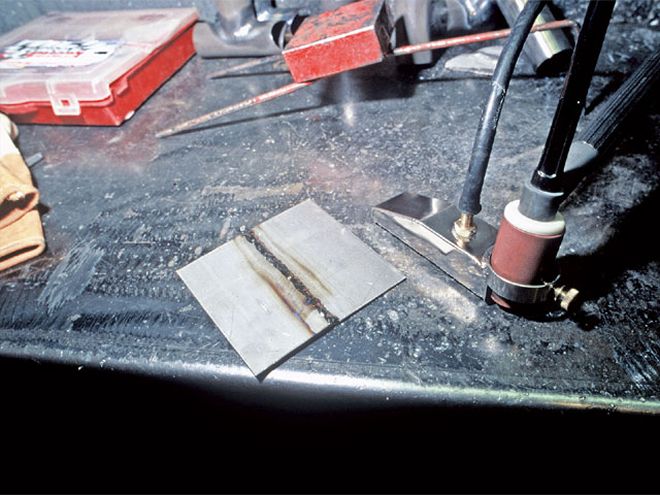

This is what you'll weld in the advanced class. The tubing is chrome-moly, the single plate to the left is titanium, the two plates are Inconel, and the tranny tailshaft on the right is magnesium.

This is what you'll weld in the advanced class. The tubing is chrome-moly, the single plate to the left is titanium, the two plates are Inconel, and the tranny tailshaft on the right is magnesium.

There are a few benefits that aren't listed in the school's brochures. One is the use of nearly any kind of welder in its vast inventory. It's the perfect chance to testdrive a welder you've been thinking about adding to your shop. In what may be the biggest surprise (but not a surprise anymore because we're telling you), students get a discount on any Lincoln product they may want to purchase. That includes the Harris line of oxyfuel gas welding equipment and air regulators for pit guns.

Another cool feature is a night out, compliments of Lincoln. You may go out for dinner, or you may even end up at the shop of the Cleveland Crawford Auto Museum to help put a car together over pizza and drinks. It's a great chance to get to know your fellow students, who will most likely help you learn by trading their own welding tricks and the new methods from the school. In the advanced class we attended, there were a few NASCAR fabricators who wanted to make themselves more marketable. It's simply a great opportunity.

When the instructor demonstrates each type of welding, there's plenty of opportunity to see it done correctly. The small number of students in the class makes it easy to see what's going on.

When the instructor demonstrates each type of welding, there's plenty of opportunity to see it done correctly. The small number of students in the class makes it easy to see what's going on.

Along with the variety of equipment you can testdrive, the folks at Lincoln can show you new equipment you didn't even know you needed. For example, we saw a portable TIG welder. Lincoln markets a line of Invertec inverter TIG welders (some with shoulder straps) that can be easily transported and stowed away on the hauler. These advanced inverter-based units allow the user to change the frequency, and therefore the size and focus, of the arc cone. It's truly amazing what these little red boxes (with only a portable generator to power them) can do when you need to make an emergency repair at the track.

Another new item was Lincoln's latest design of its Ultrashade welding helmets with instant-on, auto-darkening lenses. A cool feature controls the proximity of the helmet to your eyes. That's great for those wearing glasses, safety or otherwise. Also, the sensitivity of the lens is adjustable for the kind of welding you do. Did you know that a TIG arc is more intense than stick or MIG, even though it casts less light? We've all seen the cheap models out there and wondered if they were worth it or not. Ask yourself if it fits the crash helmet criteria. In other words, if you have a $25 head, buy a $25 helmet. What are your eyes worth when welding precision parts?

Along with digesting a great deal of new welding info, you get to learn about the equipment that can help you the most. It's also an opportunity to tell the instructors your welding problems and see what they have to solve them.