If you're planning to drive your hot rod or custom (and why wouldn't you?) you need to make sure the engine, transmission, third member, and driveshaft are all working together in harmony. The piece of this puzzle that would seem to be the simplest, as it has the least amount of moving parts, is the driveshaft. We had a pretty good idea how to set up a one-piece driveshaft, but the question of the proper method for a two-piece unit came up, which also brought up the question of just when a two-piece is necessary.

We decided to go to the experts and ask. Greg Frick at Inland Empire Driveline told us the following: "A driveshaft explodes at an rpm called critical speed. In theory, critical speed depends on shaft length, weight, diameter, and rpm. In the real world, critical speed is lowered by U-joint angles, shaft mounts, and even the engine's firing. Keeping safely away from critical speed affects decisions about driveshaft tube diameter and the decision to use a two-piece shaft set with the added support when bridging long spans. Some cars will require a two-piece driveshaft system because of overall length or because of obstacles that must be avoided. Long wheelbase cars, lowered cars, airbagged, and X-frame cars all fall into this category. While the '58-64 Chevrolet cars are the most common example, long classics that had torque tubes are some others.

Some applications, such as '58-64 Chevy passenger cars, use a coupled joint with a slipping member (top) to assist with movement of the rear suspension. Vehicles equipped with a little more horsepower are recommended to use a two-piece driveshaft with a forged stub inside a heavy-duty carrier bearing (bottom).

Some applications, such as '58-64 Chevy passenger cars, use a coupled joint with a slipping member (top) to assist with movement of the rear suspension. Vehicles equipped with a little more horsepower are recommended to use a two-piece driveshaft with a forged stub inside a heavy-duty carrier bearing (bottom).

"Two-piece shaft systems are the means used to reduce critical speed where long spans exist," Frick continues. "As described above, the critical speed of any shaft is a theoretical number reduced by both the physics at work in the shaft and by the uncertainties of the installation. While there are some guidelines showing recommended maximum shaft lengths at various rpm, judgment is required when these lengths are approached. While each vehicle is different and no hard and fast length rule applies to all cases, start asking questions when your driveshaft measures 51 inches or more." The first major advantage involved with the selection of a two-piece driveshaft is diameter. As a driveshaft gets longer, you must increase the diameter to maintain its overall strength. Splitting a driveshaft into two smaller-diameter pieces comes in very handy where space is an issue (an almost certain concern that becomes more important when the car is lowered).

The two smaller-diameter units, beyond fitting much easier into limited space areas like X-members and driveshaft tunnels, also run much smoother than their larger-diameter counterparts. "A two-piece driveshaft is a great item when built and balanced correctly," says Denny Bringhurst of Denny's Driveshafts. Denny also reiterates that two-piece units will allow the driveshaft to maintain a higher critical speed, which is essentially a redline rpm maximum of a driveshaft. "As a driveshaft spins faster, the higher the chances of a slight imbalance causing a wobble, which can lead to failure and breakage within the driveline itself," Denny warns.

Jeff Gilroy of Inland Empire Driveline adds that "strength increases the larger you go in diameter and single-wall aluminum is better for strength." He also points out that there are two styles of two-piece driveshafts. The first is a "mid-shaft," which uses a slip-together "telescoping" joint and is recommended in lighter-duty applications not using extreme horsepower, and the second style is the "Jack shaft" design that uses a bolt-together yoke to mate the two halves of the driveshaft, which is often used in high-horsepower applications that will see extended punishment.

For even higher-performance applications an aluminum driveshaft is recommended. This type of driveshaft will spin truer at higher rpms than the steel counterpart.

For even higher-performance applications an aluminum driveshaft is recommended. This type of driveshaft will spin truer at higher rpms than the steel counterpart.

Both designs may or may not use a carrier bearing depending on your specific application. Parameters that will determine the type of carrier bearing (pedestal or U-bracket style) you use will depend on the space available, among other things. Consult your driveshaft specialist to determine what type of joint and support bearing your driveshaft requires.

When setting up a one-piece driveshaft, all the experts agree that the engine and transmission should be set in the chassis with the rear approximately 3 degrees below horizontal (a magnetic protractor can be used to check this angle). In the rear, the angle of the rearend pinion will be set to 3 degrees above horizontal. When the car is finished with all the weight added you should recheck the pinion angle. If any added weight has changed the pinion angle, correct it. Leaf spring-equipped vehicles can be adjusted with shims available from alignment shops, and on four-link-equipped vehicles, the links are designed to be adjusted to dial in a perfect pinion angle.

All three working angles should add up to zero. The easiest way to do this is mounting the front shaft section so it has zero degrees through the joint at the transmission and then treat the rear shaft as if it were a single shaft.

All three working angles should add up to zero. The easiest way to do this is mounting the front shaft section so it has zero degrees through the joint at the transmission and then treat the rear shaft as if it were a single shaft.

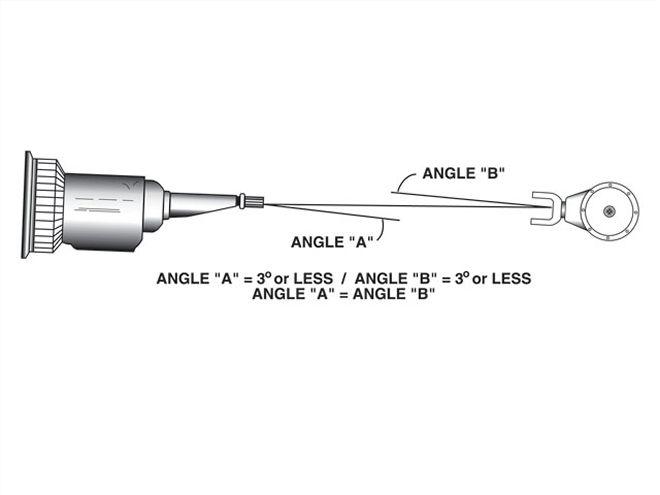

Angle setup for two-piece shafts is similar to the one-piece. All three working angles should add up to zero. The easiest way to do this is to mount the front shaft section so it has zero degrees through the joint at the transmission. The rear shaft may then be treated as if it were a single shaft. Sometimes this is not possible and all three angles must be juggled to arrive at zero. It is a good idea to allow for some up and down adjustment at the center support mount so the angles may be tuned as necessary once the car is driven. Vehicles that do not have the proper angles set in the driveline components will experience pulsations that will cause vibration in seats, mirrors, gearshift levers, and other miscellaneous parts. These pulsations can also destroy transmission clutch packs, tailshaft housings, rearend bearings, gear sets, and axles. Another concern in this area is a compound angle that comes about if the centerline of the differential is not in direct line with the centerline of the engine and transmission. Luckily most rodders are visual conscious when setting up the rearend and use housings with the pumpkin centered perfectly in the center of the vehicle. Pay equal attention to avoid any compound angles while setting up the engine/trans relationship to the rearend. Setting up the components right from the beginning can save a lot of frustration and costly repairs down the road.

Once the components have been properly set up on both ends it's time to measure for your new driveshaft. When it came time to figure out each of the two-piece shafts' lengths, Frick states, "There is no hard and fast law governing shaft lengths. It is customary, though, to divide the overall length 40-percent front and 60-percent rear. Our experience with motorhome manufacturers has taught us not to make either shaft, especially the front shaft, shorter than 18 inches. Available crossmembers, frame obstacles, and U-joint angle cancellation will all play their part in dividing up the span." Both Denny's Driveshafts and Inland Empire Driveline make this process easy with detailed instructions and order forms on their Web sites. What you'll need to know is what type of transmission you are using (for slip yoke spline application) and what size U-joint you are using at the third member yoke. When making your measurements, the vehicle must be on the ground at operating height (jacking up the vehicle will change your dimensions). Measuring for a two-piece drive shaft is similar to measuring for a one-piece unit. The major difference involves noting the location of the carrier bearing for the driveshaft joint if one is being used.