Got a tech question? I'll try to answer as many of them within the magazine or on the Web site as space permits. Here's how to write:

Snail Mail: Hot Rod Pit Stop, 6420 Wilshire

Blvd., Los Angeles, CA 90048

E-MAIL: HOTROD@primedia.com; include "Pit Stop" in the subject line, and don't forget to include your real first and last name (not screen name), and hometown or military unit, base, or ship in the message.

FAX: 323/782-2223

Auto Trans ID

My '69 Dodge Dart GT is the first Dodge I have ever worked on. It has a 318 with a TorqueFlite trans. How can I tell whether the trans is a 727 or a 904?

Wes Belzung

Via e-mail

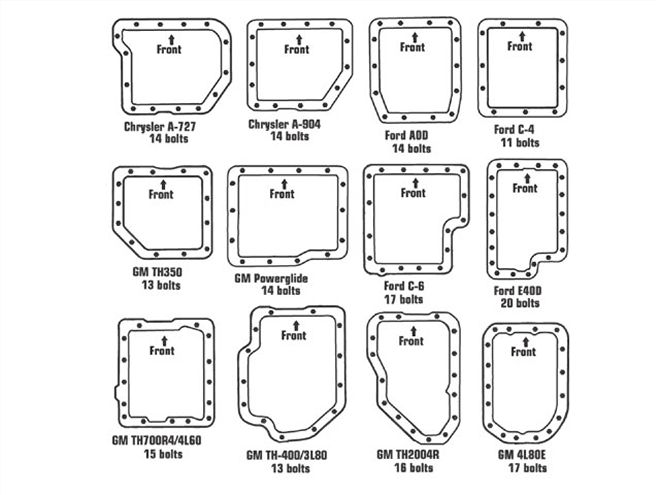

Assuming the drivetrain is stock, the trans is almost certainly a 904. If in doubt, the easiest way to identify any manufacturer's auto trans is by the shape of the pan and the number of pan mounting bolts. The accompanying illustration, adopted from information provided by B&M, shows the pans of popular automatic trannies.

Torque Angle Meter

I am going to install an underdrive pulley/harmonic balancer on my '99 LS1 Camaro. The shop manual gives the following instructions for tightening the crankshaft balancer bolt:

1.Tighten the crankshaft balancer bolt a first pass to 50 N·m (37 lb-ft).

2. Tighten the crankshaft balancer bolt a second pass using a torque angle meter.

What is a "torque angle meter" and what is the purpose of the second pass?

John Smith

North Wales, PA

Great question! I consulted ARP's Chris Brown (a premier bolt guy), the School of Automotive Machinists' Judson Massingill (a premier automotive-machining instructor and LS1 racer), and Westech Automotive's Norm Brandes (who works on a bunch of late-model as well as classic engines and has direct contacts in the OEM engineering community). The gist of their comments requires an understanding of how bolts work. All bolts stretch or elongate when tightened. How much they stretch depends on the bolt's material, heat treat, ductility, diameter, length, and thread pitch. Measuring bolt stretch is the most accurate way to tighten bolts because it disregards the varying effects of friction, lubricants, bolt plating, and out-of-calibration torque wrenches. High-end rod bolts in professionally built engines often have a published stretch value. But other than rod bolts, in the field the end-user rarely checks stretch; it's just too time-consuming and (on blind fasteners like head bolts, main-cap bolts, and crank bolts) it's not practical without really sophisticated equipment. That wasn't a problem in the past because engineers designed fasteners on old-school engines to generate adequate clamping power when tightened to well short of the yield point, which is the point at which the bolt undergoes permanent elongation and will not return to its original preinstallation length if it is loosened and removed. With bolts tightened to less than their yield point, torque wrenches-even those not routinely calibrated-were, as Homer Simpson would say, "Ahhh, close enough."

However, the stock critical fasteners on many of today's high-tech late-model engines like the Chevrolet Gen III small-block (includes LS1, LS6, and '99-and-up small-block pickup truck engines) are a torque-to-yield design. OEM engineers claim this generates better preload under varying conditions, making the fastener less likely to loosen. Cynics might say it's a way of scraping by with cheaper materials. (And I might add that on 8,000-rpm LS1 racing engines, SAM reports that even when installed per GM's installation procedure and using "blue" medium-strength thread-locking compound, the stock bolt still comes loose after 25 quarter-mile passes unless it's retightened.)

At any rate, a torque wrench cannot accurately establish preload or tightness on a torque-to-yield application. Once the fastener starts to yield, continuing to tighten the fastener won't show any increase or change in the torque value registered by the wrench-but the bolt just keeps yielding until failure. Depending on the fastener design and material spec, the point between initial fastener yield and outright failure can vary-it can be like a sharp pyramid peak (you fall off the deep end real quick after hitting the peak or initial yield point), or it may have a flat crown (the bolt can be tightened well past yield before it's strength curve degrades toward failure). Note that even on a bolt that's, say, torqued to 90 percent of yield, you can get into trouble with bolt materials that exhibit a peak-like strength curve if using improper lubricants for the published torque value and/or an out-of-calibration torque wrench.

This is where the torque angle meter comes in. A conventional torque wrench is first used to seat the bolt just snug to a fairly low threshold for the fastener size. Next a torque angle meter is attached and the bolt is turned a specified number of degrees to establish the correct stretch/tightness. This works because the OEM engineers undertook extensive experimentation to determine how much stretch occurs per degree of rotation for the particular bolt design. The result is a tightening method that is significantly more accurate than a torque wrench, especially when tightening to or after the yield point.

The other point about torque-to-yield bolts is that you should not reuse them. In fact, the GM balancer installation procedure is to use the old bolt to initially seat the balancer on the crank, then remove it and install a new bolt according to the instructions you quoted. You don't reuse the old, now-yielded bolt because the next time you tighten it, the bolt will stretch even farther, risking sudden bolt failure.

There is a simple and effective workaround to all this if you don't want to buy a torque angle meter; it will also give you a stronger, more reliable fastener: Use ARP's premium-quality bolts. They're made of much better material than the stock stuff, so even when tightened to just 75 percent of yield (a percentage that provides plenty of cushion for out-of-calibration torque wrenches), the resultant clamping force is higher than that generated by a stock fastener torqued to yield. And since they're not tightened to yield, an ARP fastener can be reused indefinitely. ARP PN 234-2503 is the correct M16x20 metric fastener for the GM Gen III small-block damper. Tighten it to 110 lb-ft using ARP assembly lube or 140 lb-ft using SAE 30 oil. And remember: These torque values are not valid for stock fasteners, which are made from a completely different material.

50CI Olds Stroker

Where can I find a 500ci stroker crank for a '65 Olds big-block 425?

Jason Caballero

Jersey City, NJ

It's a bit more complex than just grabbing a stroker crank. Building an Olds this big also requires custom pistons and rods, plus clearance-grinding the cylinder bottoms to clear the connecting-rod beams. Dick Miller Racing (DMR) offers a $3,399 4.500-inch-stroker crank kit that when installed in a 0.060-over (4.185-inch bore) 425 yields 495.2 ci. The basis of the kit is a reground 455 cast crank: The original 4.25-inch-stroke crank's 2.5-inch Olds rod journals are offset-ground to the 2.2-inch big-block Chevy size, yielding a 11/44-inch stroke increase. The crank's oil holes are cross-drilled, the bearing journals are chamfered, and the whole assembly is balanced for the included Oliver 7.00-inch center-to-center big-block Chevy rods and custom forged pistons. Also supplied is a 455 damper and flexplate or flywheel, main bearings drilled for better oiling, moly file-fit rings, a complete overhaul gasket set, freeze-plugs, and miscellaneous attaching hardware.

Normally the customer supplies a block, heads, cam, timing chain, intake manifold, and exhaust headers, but Miller can also assemble an entire engine for you using the kit as a basis. The accompanying graph shows the torque curve from a 0.030-over version of this engine (488 ci) built by Miller. Major parts in the build include Diamond custom pistons (10.33:1 compression ratio), DMR street/strip-ported Edelbrock heads, a Holley 750-cfm square-bore carb atop an Edelbrock Performer intake, cast-iron exhaust manifolds, and a custom DMR hydraulic flat-tappet cam (PN DMR-CC-230-236: 230/236-degrees at 0.050, 0.522/0.522-inch valve lift, 112-degree LDA).

When assembling my big-block Chevy engine, I noticed that the cam gear and the crank gear were not on the same plane. I measured this difference as between 0.077 and 0.080 inch. That was with a 0.031-inch block protector installed, so previously this engine ran stock with the gears out around 0.050 inch. Will this affect the cam and lifters in any way?

Ray Barnhart

Conneaut, OH

Misalignment has little effect on a conventional flat-tappet cam and lifters. It's more critical with a roller cam, but that can be minimized with an "antiwalk" cam-nose button. However, any cam and crank sprocket misalignment over 0.015 inch negatively impacts timing-chain longevity. Fortunately, it's relatively easy to correct. If the top (cam) sprocket's too far forward, machine its rear block-saver/ Torrington bearing groove deeper to make up the difference; if the top gear is too far toward the rear, shim the rear groove (Cloyes offers different-thickness spacers for this purpose) and/or machine the rear of the bottom (crank) sprocket or crank shoulder against which the bottom sprocket seats.

'84 Mustang Brake Upgrade

My '84 Mustang LX is making whining noises and clunking in the rearend. It has a 5.0 V-8 and a four-speed auto. The rearend is stock with four-lug wheels. Rather than repair this rearend, is there a stronger factory rearend with five-bolt axles that will bolt in? Will I encounter any driveshaft problems? How about bolt-on five-lug wheels and rotors from the recycling yard?

Jim Malloy

Albany, OR

There are multiple wrecking yard answers to your question. I've outlined two of them below-what may be turned the "minimalist" approach, as well as the "balls-out" approach that not only gives you five lug wheels, but also larger four-wheel-disc brakes. Personally, I'd go for the big four-wheel discs; why else bother to convert to five-lug wheels in the first place?

The Minimalist Approach, as recommended by Dave Freiburger: Get an '86-'93 Mustang 8.8-inch four-lug-wheel rearend (Hollander Salvage Yard Interchange 1466). Replace the right and left Mustang axles with any of the following five-lug axles: two lefthand '83-'92 Ford Ranger pickup, two lefthand '84-'90 Bronco II, two righthand '92-'97 Aerostar van, or both axles from an '86-'91 Aerostar (these are all dimensionally the same, Hollander 1338). This option retains the original rear drum brakes. Installing rear discs requires aftermarket parts because factory disc setups are designed for slightly wider disc-brake-style rearend housings (see below).

Up front, replace the existing Mustang four-lug brake rotors with five-lug rotors from an '83-'94 two-wheel-drive Ranger; '94 Mazda two-wheel-drive B-2300, B-3000, or B-4000; '86-'89 Aerostar (all); or '90-'91 two-wheel-drive Aerostar (Hollander 1575). Some models may use different wheel bearings; replace them if necessary. Important!: The rotor diameter must be reduced (turned-down) by 0.125 inch in a brake lathe to avoid interference with the existing '79-'86 Mustang spindle.

The Balls-Out Approach, as recommended by AEW's Mark Sanchez: Get a '94-'98 Mustang 8.8-inch rearend (Hollander 1815). Although slightly wider flange-to-flange, it physically bolts in place of your existing rear. It already has the five-lug wheel bolt pattern plus rear disc brakes. A '94-'98 Cobra rearend (Hollander No. 1816) has even larger rear discs. Either way, get the entire rearend complete with parking brake cables.

Up front, for a wrecking-yard front five-lug conversion that preserves correct suspension geometry and results in larger 11-inch front discs (the original rotors were 10-inch), use the following parts combo: '87-'93 Ford Mustang 5.0 front spindles; '82-'87 Lincoln Continental or '84-'92 Lincoln Mark-series rotors; '83 to early '90s big Ford, Lincoln, and Lincoln Mark series calipers and brake hoses; and a '79 Lincoln Versailles four-wheel-disc-brake-compatible master cylinder. Brake components may vary slightly among these different model years (including hose design and ABS interface), but that should not affect physical interchange onto your car. Variations in terms of support or nonsupport of ABS is not a factor for this retrofit since the ABS won't be active. Some of these parts or close relatives may also have been used on other, more esoteric applications such as early '80s Mustang SVO turbo cars. The accompanying table lists typical direct replacement part numbers for an '89 Lincoln Mark VII (except for the master cylinder and spindle, which are from different vehicles as noted); if you go the wrecking-yard route, the Hollander No. can be used to cross-reference to other models with physically interchangeable parts. Ernie Fernandez at Sunrise Ford, a with-it Ford parts guy, supplied the original Ford part numbers for reference.

Using the later Mustang spindle may require a MacPherson strut change. Some aftermarket struts came with optional spacers that allow the same parts to work on '79-'93 Mustangs. This spacer is required with aftermarket struts and '87-'93 spindles, or (if you can find one "loose") when retaining the original Ford '79-'86 strut and using the '87-'93 spindle. Ford factory '87-'93 struts work directly with the '87-'93 spindle without the need for a spacer.

If necessary to optimize front and rear brake distribution, it may be necessary to "gut" the factory proportioning valve (retaining the valve as a distribution hub and low brake fluid warning system), and install an in-line, user-adjustable proportioning valve in the line to the rear brakes. Ford Racing is one source, PN M-2328-C; it also sells a variety of new, integrated, front-and-rear disc-brake conversion and five-lug upgrade kits.

Five-lug wheels from the previously listed Lincoln caliper/ rotor donor cars as well as the Ford Ranger pickup truck fit both the front and rear on both minimalist and balls-out approaches. For the balls-out approach only, '94-'98 Mustang wheels work out back and have the right offset to compensate for the slightly wider late-model rearend (grab 'em when you score the rear), but the '94-'98 front wheels have the wrong offset for the earlier car.

Where Do I Get

...larger cross-drilled rotors and better calipers that bolt onto an '02 1500 Silverado without any major modifications?

Andrew M. Kinal

Via e-mail

Stainless Steel Brakes Corp. (Clarence, NY; 800/448-7722 or 716/759-8666; www.ssbrakes .com) has what you need. Up front, use its FX4 kit (PN A126-29), which includes Force 10 four-piston calipers and 14-inch slotted rotors (drilled rotors tend to crack under prolonged everyday use). The rear calipers are more than adequate, but Stainless offers an upgraded rear rotor package and high-performance pads (PN A2351021).

...aftermarket parts for an 8.1L (496ci) Chevy in an '03 heavy-duty pickup, including headers, a better throttle-body, a performance module for the computer, and a lower-temp thermostat?

John Kozak

Richmond, TX

T Byrne Motorsports (Westport, MA; 877/4-TBYRNE [orders] or 508/679-9760 [tech]; www.tbymemotorsports.com) has all these parts and more, including complete integrated power packages.

...plastic rechromed, or chromed if it wasn't chromed before?

Debbie Medine

Via e-mail

Several places, including Crown City Plating Co. (El Monte, CA; 800/982-3091 or 626/444-9291; www.crown-city-plating.com); CV Vacuum Platers Inc. (Mission, BC, Canada; 877/763-2323 or 604/820-9571; www.cvvacuumplaters.com); and Layson's Restorations (Auburn, WA; 877/930-4088; www.laysons.com).

...in touch with a specialist who has squeezed more power (naturally aspirated or turbo) out of the 2.5L Chevy four-cylinder motor?

Peter Barnes

South Africa

This engine family began life as the 153ci Chevy II four back in the '60s and eventually evolved into the Pontiac "Iron Duke" 2.5L of the late '70s and '80s. For typical street mods and advice, surf to www.dukemods.50megs.com. Clifford's Inline Performance Products (Temecula, CA; 909/303-2333; www.cliffordperformance.com) offers headers and intakes. Somers' (Canton, ME; 207/597-2100; www.megalink.net/~jsomers) builds all makes of inline-four and inline-six engines and has an Iron Duke R&D program underway. For hard-core full-race stuff, there's Gaerte Engines (Rochester, IN; 574/223-3016; www.gaerteengines.com), which even has an aluminum Iron Duke-based Sprint Car block.

...hot rodding parts for the 425/472/500ci Cadillac, including the bottom end and valvetrain?

Patrick Curren

Norman, OK

Everything needed to build a complete performance Caddy engine is available from the Cad Company (Albuquerque, NM; 505/823-9340; www.cad500parts.com) or Maximum Torque Specialties (Delaven, WI; 262/740-1118; www.500cid.com).

...a wiring harness to run an '87 Buick Grand National turbo V-6 with a stock computer in an older noncomputer vehicle?

Bob Caudle

Flower Mound, TX

Street & Performance (Mena, AR; 479/394-5711; www.hotrodlane.cc) can custom-build a Buick harness if you already have the computer. It also helps to have an original harness that S&P can use as a template, as some connectors are unique and no longer serviced.

...motor- and tranny-mount kits to install a 327 Chevy and 700-R4 in a '51 Ford F-1 pickup with the original flathead V-8 and nonsynchro four-speed?

Luke Neiwert

Meridian, ID

John's F-Fun Hundreds (Anaheim, CA; 714/563-F100; www.johnsf100.com) offers a Chevrolet V-8 front crossmember with pads (PN 11__5020-CA), and a universal Chevrolet transmission crossmember with pad (PN 21__D)__5025-B).

Reader Response

I think you may be sending Mr. Basegio on the wrong track in your response to his vibration concern on his '88 IROC ("Driveshaft Vibration," Pit Stop, Oct. '03). He supplied you with clues that point more toward the transmission as the culprit rather than the driveshaft or rearend. First, he states that the vibration is not present in Third gear at the same speed. Second, he states that the vibration is not present in Neutral at the same speed. This is a very important check in diagnosing a speed-related vibration. You can generally eliminate a driveline vibration with this test. A tire/wheel/prop-shaft vibration that occurs at a given speed will resonate under accel or decel. If the vibration is not present in Neutral when coasting down through a given speed, you can usually eliminate these items.

That's why I believe he has a fault in the reaction planetary gearset in his transmission. When his trans is placed in Neutral, the drive wheels are turning the axles, differential, and driveshaft. In turn, the transmission output shaft spins, driving the input planetary carrier on a 700-R4. When the transmission is in Third gear, there is no gear reduction through the transmission, giving a 1:1 ratio, meaning that the reaction and input planetary gearsets are all turning at the same speed.

Mr. Basegio primarily feels the vibration under load in Fourth gear. Since we've already eliminated the input planetary (as the vibration doesn't occur in Neutral), this leaves the operation of the reaction planetary gearset as the probable source of the problem. The fact that Basegio also said that he heard a faint "beating" sound in Second gear at 2,700 rpm only reinforces this belief, as the reaction Sun gear is held in both Second and Fourth gear by the 2-4 band. As for why Basegio didn't encounter the problem before he switched rearend gears: Most probably, he simply moved the peak resonance of the vibration to a point at which it was more noticeable.

Scott Wagner

Service Technician, ASE Master Technician, and GM World Class Technician, Michael Chevrolet Summerville, SC

Thanks for the tip!

See More

Mark Hammonds wants to put a new motor in his 250ci straight-six Maverick. I give him plenty of options at. ww.hotrod.com