E-mail your tech questions to us at carcraft@primedia.com (include the words "What's Your Problem?" in the subject line) or fax them to 323/782-2223. All correspondence must be signed with the sender's real name (not a nickname or a screen name) and include the sender's hometown and state or province. While mail cannot be answered personally, Car Craft will publish as many letters and replies as space permits. Photos are welcome, but no materials will be returned.

Maddening Motor MountsI have a '67 Mustang with no motor or trans that I purchased several years ago. The car originally had a 289 and a manual trans, but I'm attempting to install a 351W and a C6 automatic. My problem is that when I tried to install the 351, I found that it would not sit in the engine bay squarely. I'm using new stock replacement 289 engine mounts and setting the motor on the factory frame brackets, but something is obviously wrong. I've inspected the frame and done some measuring, and there is no evidence of a previous front-end collision-the car seems to be square. I've checked several parts books and they all list the engine mount for the small-block V-8 to be the same from '67 to '69. I can't check the original engine mounts because I didn't get them with the car. I realize that the 351W is a taller-deck engine than the 289, but my understanding is that the lower portion of the block has the same dimensions, and that the 289 mounts should work fine. I have another '67 that now has a 302, and I seem to recall having a similar problem some years ago when I installed a new engine and tried to use new mounts. I wound up using the old ones in that case, but what is the deal here?Steve GregoryGreenwich, CT

We've heard of this problem before, as it has confounded Mustang modifiers for years. You're right about the parts book listings, most claim that the engine mounts are the same for '67 through '69 or '70, but as we've found, this is incorrect. Apparently, the '67 Mustang uses a one-year-only engine mount/frame bracket design, and as far as we can tell, there is not currently a replacement engine mount manufactured for this application. The lack of a proper replacement is likely due to the fact that the aftermarket believes the '67 is covered with existing offerings. Fortunately, there is a relatively simple way around this: Find a set of '68 frame brackets and bolt them in place of your original '67 brackets. This will allow the use of currently available engine mounts. The '68 frame brackets are not offered new, but should not be difficult to locate-any vintage Mustang salvage supplier should be able to assist you. As for the 351W, you're right about the lower portion of the block sharing dimensions with the standard Ford small-block. The Windsor should bolt right in with the replacement 289/302-style engine mounts once you swap to the '68 frame brackets.

Valvespring VerificationI have a '78 Z28 with a 350 four-bolt main block, 0.020-over flattop TRW forged pistons, cast crank, and stock rods. It has a 750-cfm double-pumper Holley mounted to a Victor Jr. single-plane intake feeding rebuilt 491-casting fuelie heads with Manley 2.02/1.60-inch valves. The valves are 0.100-over stock stems with Z28 springs and Crane Cams 1.6:1 roller rockers. The cam is a Lunati solid-lifter, with 308 degrees duration and 0.500-inch lift. A reworked HEI sparks through a set of MSD wires. All of this runs through a Muncie M20 and an 8.5-inch rear with 3.73 gears.

The problem is that the engine won't rev over five grand. I've changed distributors, and the fuel pressure sits at 5 psi at 5,000 rpm, so the spark and the fuel are there. My question is, did my head man make a mistake by putting the stock-type Z28 springs on the valves that are 0.100 inch longer than stock, making the spring pressure too light, or is there another problem? Mick PaffordPortage, WI

You're probably on the right track in questioning the valvesprings, based on the information you provided. If your cylinder-head guy is sharp, he would have checked the spring pressures at the installed height, which would have revealed the lower pressure that could have been caused by the longer valve-stems. However, if this guy is a production shop employee rather than a performance shop technician, chances are also good that his idea of acceptable seat pressures are not sufficient for your application. That's a pretty healthy cam, and the fact that it's a solid-lifter setup just contributes to the extra load placed on the valvesprings at high rpm. If your head guy set up those springs for 100 pounds on the seat, which wouldn't be unheard of for a regular production valve job on a small-block, you'd almost certainly be experiencing valve float at high rpm. There is another factor to consider, though: The "Z28" valvesprings you refer to are common machine-shop items, and are only marginally better than standard replacements. For a typical engine, they make a nice upgrade from stock, but for a high-winding small-block with a lumpy solid cam, they're really inadequate. The tech guys at Lunati agree, and recommend upgraded springs to accompany that cam. Check the valvesprings for seat pressure and pressure at maximum lift-in your case, 0.500-inch. You should see 125-140 pounds on the seat and somewhere over 300 pounds (but not more than 400) at max lift. The Lunati guys feel this should allow you to rev well into the 6,000-rpm range with no problem.

Crossmember SolutionsI have a '79 Chevy Malibu with a 305. I put headers on my engine and want to put dual exhaust on as well. The problem is the transmission crossmember-it's designed only for single exhaust. Is there a double-hump crossmember I can use that will accommodate true dual exhaust, or do I just have to modify the stock one? If modification is the answer, do I need to be concerned about weakening the crossmember?Ken SpearAlbuquerque, NM

You could modify the existing crossmember to clear duals, and there are several ways to do it. The crudest we've seen entails heating the side that needs clearancing with a torch and bashing it with a hammer, which will still require the pipe bender to dip the pipe underneath the crossmember on that side.

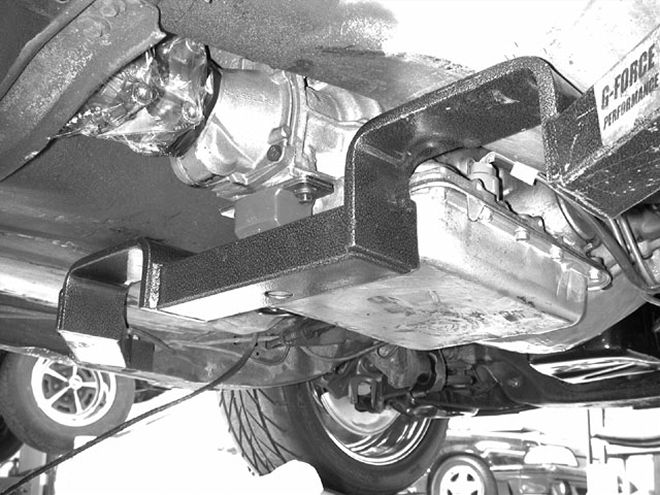

A more enlightened approach involves "notching" the crossmember by cutting out a section for clearance and then welding in another piece to reinforce the area. Of course, if you're handy with a welder, you could probably fabricate a completely new crossmember with the proper exhaust humps. However, when we faced the same challenge with our '78 Malibu project, we simply obtained a new crossmember from G-Force Performance.

The G-Force piece is far stronger than the stocker, yet maintains excellent ground clearance and features exhaust humps that are nice and large to accommodate variations in pipe routing. The price at the time (about a year ago) was $189, and was well worth it, since anything we would have fabricated wouldn't have been as nice, and attempts to modify the original would surely have resulted in a mangled mess.

Light 'Em UpCould you explain how a Line-Loc works? I know it locks the front wheels, but that's about it. How do you install one, and is it worth the time? If I did install one on my car, would I still be able to use the stock brakes to stop?Gavin ThorpeEugene, OR

A Line-Loc (Hurst's brand) or roll control is a system that can be added to the factory braking system of a car so that the driver can engage only the front brakes to assist in standing burnouts. The system is relatively simple, usually consisting of an electrically activated solenoid valve positioned in the front brake line, often close to the point where it originates at the master cylinder. To use the system, the driver steps on the brakes with a fair amount of pressure and then hits the switch that activates the solenoid valve. This effectively traps the brake fluid between the valve and the front brakes, so when the driver releases the brake pedal, the hydraulic pressure to the front brakes remains. This is how the front brakes are engaged independently of the rears. At this point, the driver can put the transmission in gear and apply throttle to spin the rear wheels without being hindered by the rear brakes while the front brakes hold the car in place. This system is intended for use on a dragstrip, where standing burnouts are a typical part of the tire-heating ritual. If you race often, you may want to invest in one-roll control kits aren't very expensive and are relatively simple to install. However, if you just want to do random burnouts, you ought to be able to modulate the brake and throttle to obtain the desired results ... just don't tell your parents/principal/local cops where you heard this when you get busted.

Overdrive AlternativeI have always wondered why overdrives are used instead of having the same number of gears in the transmission with the top gear being 1:1 and adjusting the rearend ratio to make the engine and road speed the same as in an overdrive application. What about the efficiencies of different ratios and different sizes (designs) of differentials?R.E. Carlsonvia e-mail

Carlson, huh? Sounds German. Or maybe you just think like a German, because the arrangement you propose is actually common practice on many German cars, most notably Mercedes-Benz and Porsche. Many of these cars use four-speed automatics or five-speed manual transmissions that do not feature overdriven gears. Instead, top gear is 1:1, and First gear is extra low. The end results are cruising speeds and rpm ranges that are similar, if not the same, as some overdrive-equipped vehicles. The Germans have likely opted to go this route because they favor high-speed cruising, and technically, overdrives are intended for loafing along the highway to save fuel. Accelerating in overdrive puts a heavy load on the transmission, even though many of the American V-8-powered cars we know and love can accelerate readily in OD if the rearend ratio is low enough.

Overdrives are intended to lower engine rpm at a given cruising speed, rather than as a means of increasing top speed; you may have noticed that many road tests for new vehicles list top speed in High gear, rather than in Overdrive. Having a 1:1 top gear and a numerically lower rear gear is a more durable arrangement if you plan to hold the throttle to the floor in the quest for top speed travel. Since we don't have our own Autobahn, most American performance cars are geared for brisk acceleration with the added bonus of low-rpm highway cruising through an overdrive.

However, if you seek the type of configuration favored by many Europeans for your hot rod, investigate the Richmond five-speed manual trans. It was intended as a bolt-in replacement for many traditional four-speed transmissions, and features a 1:1 Fifth with several available gear spacings, all utilizing a fairly low First gear. We've seen plenty of street cars using this transmission that were running rearend gears in the neighborhood of 3:1 or less while still enjoying strong acceleration.

B-Body InterchangeI have a '79 Caprice two-door that I'm working on. It has a pretty basic 350 four-barrel with a TH350 trans, and worst of all, a 2.56:1 posi. I'm having a terrible time finding parts (suspension, fiberglass hood, and interior trim). I've also been told that a rearend from a '94-'96 Impala or Caprice will bolt right in. Any information you could give me about any of this would be a huge help.C. J. JamesArlington, TX

Not too many people modify fullsize Chevys of that vintage, so finding specialty performance parts like fiberglass body panels is going to be tough, if not impossible. Similarly, replacement interior panels and parts are going to be limited to lucky N.O.S. finds. Make friends with the local GM parts-counter guy so you can get him to scan the national inventory for obsolete stuff that may still be sitting on a shelf somewhere. Then start scouring eBay; the good part about searching for parts for less-popular cars is that the likelihood of being outbid is appreciably lower than if you were chasing stuff for a Camaro or Chevelle.

The good news is that the chassis under your Caprice is the same from '77 to '96, so you can bolt on the good stuff from some of the better models, including the '94-'96 Impala SS. The rearend from the Impala SS is an 8.5-inch 10-bolt, which is plenty stout, and the gearing is 3.08:1; posi-traction was standard. If you find a police-package car of the same vintage, a 5.7L equipped model will also have 3.08s, and most have posi-traction. A police-package car with the 4.3L Gen II V-8 will have a 3.23:1 rear gear, while some earlier police-package models had 3.42 gears (around '90). Note, however, that all police-package cars as well as the Impala SS use the larger 5-on-5-inch lug pattern, while your car has a 5-on-4.75. But, finding a good rearend from a cop car or Impala might be a good excuse to swap the front brakes to the larger 12-inch setup found on those cars (yours are 11-inch), as well as on station wagons, which also have the 5-on-5 pattern. By the way, the Impala and '94-'96 police cars also have rear disc brakes as a bonus.

Correction...On page 96 in the Apr. '03 What's Your Problem ("Killer Cougar?"), you recommended that the owner of the '91 Cougar find a roller-cam-compatible block rather than building his current one. Just wanted to correct you: All '87-and-later Ford passenger cars were roller-cam equipped from the factory. An H.O. and a non-H.O. block are exactly the same. The only difference between a non-H.O. short-block and the (Mustang/LSC) H.O. short-block were the pistons and the camshaft, both still being roller, just with a different firing order, lift, and duration figures. As an aside, Ford trucks in the late '80s and early '90s were equipped with roller-cam blocks as well, but were shipped from the factory with flat-tappet cams installed.Matt Footevia e-mail

Thanks, Matt. All the late Ford pushrod V-8s we've dealt with were H.O. versions; the switch to roller blocks across the board escaped us.