We can remember when the very first reproduction frames arrived on the scene, they were the oh-so basic Model T and Model A frames built to support the burgeoning street rod hobby. That was in the '60s, and proof of just how far our hobby has come is evident in the number of complex chassis available for cars today, cars that were once considered "late models." One of the leaders in the reproduction chassis market is the Charlotte, North Carolina–based, Fatman Fabrications. It is here that Brent "the Fatman himself" Vandervort and his team of talented technicians fabricate a wide array of suspension kits and complete chassis for virtually any car you may be building. Fatman Fabrications also has an installation shop; if Fatman makes it, they can install it too.

Fatman Fabrications recently introduced a complete chassis for the popular 1955-56 Thunderbird. The response was very good, but the order desk was frequently asked, "When are you going to do a chassis for the fullsize 1955-56 Ford?

Well it didn't take long for Vandervort to fill the need as he just happened to own a 1956 Ford Fairlane Victoria used as his daily driver. Brent is still a very active hot rodder, when he's not busy running Fatman Fabrications he can be found in his home shop working on one of his own street rods or fabricating pieces for his vintage airplane. And so, one nice red and black 1956 Ford was driven into the shop as a test mule for the new 1955-56 Ford frame. This car was the perfect candidate as it was a basically stock, never altered car, from the Y-block motor to the rear bumper.

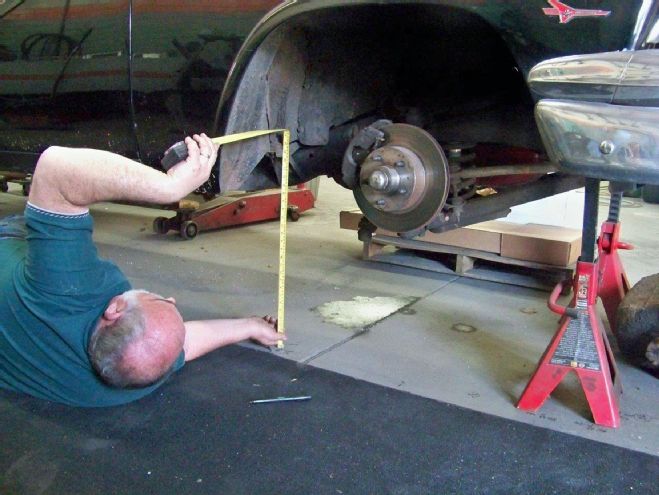

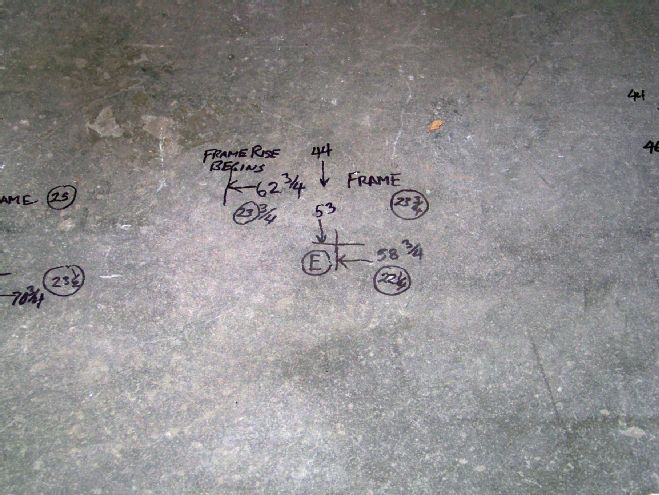

With the car in the shop Vandervort set about taking key measurements so he could draft the blueprint for the new frame. Now you many think this is done with a series of lasers connected to a laptop, but you'd be mistaken. While Vandervort's engineering degree no doubt contributes greatly to his ability to accurately determine key locations, the measurements are derived from a group of "exotic tools" that include a plum bob, a square, a tape measure, an angle finder and a sharpie. Of course like any tool, they are only as good as the man using them.

Armed with the critical measurements Vandervort went back to the drawing board, which this time actually is a computer and proceeded to complete his calculations and draft a blueprint for the chassis along with the complete front and rear suspension.

Armed with this new drawing, team Fatman proceeded to fabricate the 'rails, crossmembers, driveshaft loops, and suspension components. The engine mounts and body mounts were only tack-welded in place in case minor adjustments were required.

Speaking of the motor, Vandervort decided it was time for a completely new modern driveline so the old Y-block would remain in the old chassis, replaced by a new-age Ford 4.6 motor coupled to a 4W70R transmission. Mounting this very wide motor in the confines of a 1955-56 engine looked like it could be a real challenge. We were all pleasantly surprised when the 4.6 fit very nicely, without so much as a cut in the firewall.

The power from the 4.6L Ford motor passes to the 4W70R tranny and through a driveshaft loop to a 9-inch Ford rearend from John's Industries. A four-link rear suspension locates the rear, while RideTech coilover shocks provide suspension.

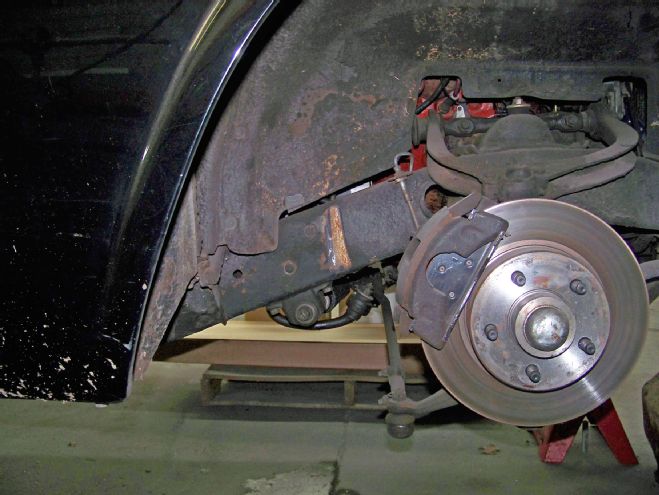

Up front the Fatman Fabrications–designed front suspension employs RideTech coilover shocks, standard 11-inch disc brakes, and a 1979-93 Mustang power rack-and-pinion steering bringing the performance of this old 1956 Ford into the current century. While the preliminary fitting is being done with iron brakes, Vandervort plans to utilize his upgrade brake offering, Wilwood 12-inch, four-piston brakes. It should also be noted that optional nickel plating is available for the TIG-welded tubular control arms.

Prototyping new products and frames is one of Vandervort's favorite things do, which explains the steady stream of new products that roll out of the Fatman Fabrications doors. We'll be following along on this entire 1956 Ford build, as Vandervort and Team Fatman work to convert this stocker into a very cool mild custom with modern power, braking, and steering.

In the next issue we address the final mounting of the motor and transmission, along with lowering the body onto the new chassis for the first testfit. We can tell you this much, we were amazed at how perfectly everything fit considering this was the prototype chassis. So stay tuned while we build one very cool, street-going, 1956 Ford Fairlane Victoria.

1. Fatman Fabrications is proud to announce the availability of their complete chassis for the 1955-56 Ford. It just so happens Brent Vandervort, founder of Fatman Fabrications, is building a 1956 Ford, so what a fine reason to develop an all-new chassis.

2. Prototyping a new frame begins with a clean floor and a Sharpie. Add a plumb bob, tape measure, angle finder, and a square you have all the tools required. Of course the math and know-how come from education and experience.

3. Remember that clean floor? Well that is where Vandervort makes his marks to plot the angles and distances of the framerail above. The circles and marks are all "code" for Vandervort. This is simple, but not easy.

4. From the plumb bob mark Vandervort measures up to the top of the body mount. This is the starting point for the chassis and all measurements will be relative to this location.

5. The new chassis will be designed to match the original frame slope so the stock inner fender panel will fit perfectly over the new framerail.

6. Chris Elliott has over 20 years of experience in the Fatman frame shop and enjoys the challenge of building the prototype chassis for any given application. It all begins on his frame fixture.

7. Jeff Watts is no rookie either, he's been building Fatman front suspension stubs for 22 years and here he is beginning to build the front suspension stub on the fabricating surface plate.

8. Since the finished car is designed to sit on a forward rake the front suspension crossmember is welded in place on a 2-degree rake. That 2-degree angle ensures the crossmember will be level, while the car will have a forward angle.

9. While Watts is fabricating the front suspension stub, Elliott is busy cutting and fitting the box tubing for the rear kick-up over the axle. 10. While structural integrity is job one, the team at Fatman Fabrications also provides a driveshaft loop and generous room for running a healthy size exhaust tubing through the frame. This type of planning keeps all components above the bottom of the framerails for a clean look.

10. While structural integrity is job one, the team at Fatman Fabrications also provides a driveshaft loop and generous room for running a healthy size exhaust tubing through the frame. This type of planning keeps all components above the bottom of the framerails for a clean look.

11. John's Industries provides the brand-new 9-inch housing that will mount Wilwood disc brakes. The 15x7 wheels with a 4-inch backspace will mount 235/70-15 Coker wide whites for a classic custom look.

12. The first test of the 4.6L Ford motor and 4W70R transmission is simply to determine if there is ample room for the engine and tranny combination. The exact engine location will be determined with the body on the frame to check for firewall clearance.

13. The front and rear crankshaft center heights are compared to the stock 312 measurements to get an idea of where the new motor and trans should be placed.

14. The diagonal brace adds torsional strength to the frame while allowing ample space for the exhaust system. This is one very stout frame.

15. The intermediate rail segments join the front stub with the straight main 'rails, and while this may look like an easy part of the job it is actually one of the more tricky portions of fabricating the frame.

16. A lot of sub-component fabrication goes into producing a modern street rod frame. Here we see the body mounts cut to size waiting to be tack-welded to the frame. In 1956 Ford did not scrimp on the number of body mounts.

17. The frame is now fully welded and the body mounts are tacked in place well enough to permit a preliminary test-fit of the body on the frame

18. Up front the suspension is a Fatman design incorporating power rack-and-pinion steering, tubular control arms, and RideTech adjustable shocks with standard 11-inch brakes. During final assembly the brakes will be upgraded to 12-inch Wilwood units.

19. The John's Industry 9-inch rear is located with a four-bar arrangement with a sway bar wrapping neatly under the housing. Another set of RideTech coilover shocks and Wilwood brakes will be employed out back.

20. Looking toward the rear of the frame it is apparent this is one very strong, modern frame able to support your 1956 Ford and provide superior handling, braking, and strength in the process.

21. One look at the original 1956 Ford chassis with its minimal K-member and it is easy to see there is plenty of room for improvement.

22. The center of the frame features parallel inner 'rails that are far superior to the original Ford frame. The frame design allows ample room up front for virtually any size motor and transmission combination.