It's been said that street rodders will suffer for vanity's sake and put up with a vehicle that is uncomfortable as long as it looks good. While that may be true for some, if you like to see the odometer spin on a regular basis your car's competence, particularly in the area of ride and handling, should be held to a higher standard.

As the team at RideTech explains it, shock absorbers are the brains of the suspension system, and nothing influences ride and handling more. Despite the critical nature of these components, at one time shocks for street rods were selected based on what would fit the space available. Case in point, the rear shocks from 1963-67 Corvettes were often used because they were short—but just because they would fit didn't make them right. Fortunately, we now have shock absorbers designed especially for needs of street rodders.

The name shock absorber is actually somewhat misleading—in Europe they're referred to as dampers, which is a more accurate description of what they do. Basically, a piston in an oil-filled tube is forced up and down as the suspension moves. The oil passes through holes in the piston, which causes resistance to the movement. As these orifices have one-way valves, the resistance on compression and extension can be different. However, in both movements the energy absorbed creates heat that must be dissipated by the shock's body.

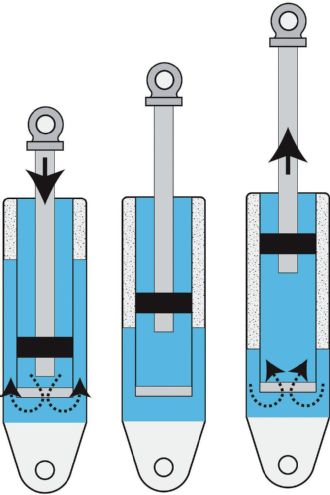

Although all contemporary tube shocks operated in a similar fashion, they can be divided into two categories: twin tube and mono tube. As the name implies, twin-tube shocks have two cylinders, one inside another. The inner cylinder, called the working tube (or pressure tube by some manufacturers) is where the piston and shaft move up and down. The outer cylinder, called the reserve tube, serves as a reservoir for the hydraulic fluid. These shocks normally contain Nitrogen gas, either in a bag or mixed with the hydraulic oil, to keep the fluid from foaming.

Twin-tube shocks are used in many OEM applications, usually with soft valving, as passenger comfort is often the main goal. Twin-tube shocks are less expensive to produce than the mono-tube design but can be more susceptible to aerating the fluid in performance applications, which can adversely impact their effectiveness.

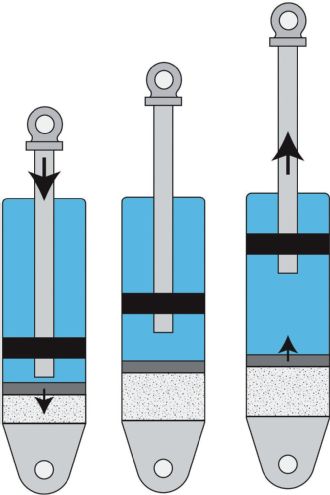

Mono-tube shocks, again as the name implies, have a single tube. However, it is divided into two sections: one that contains oil, the other gas. In the fluid chamber, motion of the chassis is transmitted via a rod that moves a piston through the oil. Below the oil is a floating piston and seal that keeps the gas trapped in a separate portion of the tube. During normal operation the piston in the fluid chamber moves up and down and the piston's compression and rebound valving determine resistance. When more aggressive suspension movements occur oil can't flow through the compression valves of the piston fast enough and as a result the floating piston is pushed further into the gas section, which increases damping force.

RideTech's shocks are the mono-tube design and come in two basic configurations. The first we'll look at are the smooth body Q-series 1-1/2-inch-diameter shocks for stand-alone use. They come in a host of lengths, and mounting styles are available to suit virtually any application.

The non-adjustable RQ series is the simplest version of RideTech's mono-tube shocks. There are no external adjustments as the valving is factory calibrated to the vehicle and the driving style of its intended use. For confident handling and stability, and for those who want to install a shock and forget it, these are a great choice.

For those looking for the ability to tune their car's suspension the HQ series shocks have a single adjustment to change the rebound [extension] properties. Adjusting the rebound setting allows the ride quality and handling characteristics to be optimized.

RideTech's second shock series are a 2-inch-diameter threaded body style. They can be used for stand-alone, coilover, and ShockWave applications. Like the smooth-body Q-series, these shocks come in RQ non-adjustable and HQ single-adjustable versions.

For additional suspension-tuning capabilities RideTech offers the triple-adjustable TQ threaded body shocks with a single rebound adjustment and dual-stage [high speed and low speed] compression adjustment. The TQ series uses a remote reservoir that is connected with a 30-inch braided line for easy installation in a variety of applications. The high-speed adjustment allows tuning for impact harshness...potholes, speed bumps, and other harsh road irregularities that might induce a high-speed movement of the piston rod. The low speed adjustment allows tuning of ride quality, as well as the general cornering characteristics of typical road course and racetrack use. While you may not be road racing your street rod, the TQ series offers the ultimate in shock absorber adjustability.

After years of research and development the engineers at RideTech collaborated with Fox and came up with a shock absorber worthy of his company’s name. This example is a smooth-body, non-adjustable RQ series. RideTech shocks now have a 1,000,001-mile warranty.

After years of research and development the engineers at RideTech collaborated with Fox and came up with a shock absorber worthy of his company’s name. This example is a smooth-body, non-adjustable RQ series. RideTech shocks now have a 1,000,001-mile warranty.

RideTech shocks are the mono-tube style. The upper piston operates in an oil-filled chamber, below it is a floating piston that acts on Nitrogen-filled chamber.

RideTech shocks are the mono-tube style. The upper piston operates in an oil-filled chamber, below it is a floating piston that acts on Nitrogen-filled chamber.

As the piston moves in the working tube of a twin-tube shock, one-way valves that separate the two chambers control fluid flow in and out of the outer tube.

As the piston moves in the working tube of a twin-tube shock, one-way valves that separate the two chambers control fluid flow in and out of the outer tube.

In a mono-tube shock the floating piston does not move far during softer, small movements of the suspension, and gas simply provides a cushioning effect. During aggressive movements the floating piston is forced down further and faster because the valving restricts the oil in the upper chamber. That causes the oil to push on the separator piston, which compresses the gas and increases damping.

In a mono-tube shock the floating piston does not move far during softer, small movements of the suspension, and gas simply provides a cushioning effect. During aggressive movements the floating piston is forced down further and faster because the valving restricts the oil in the upper chamber. That causes the oil to push on the separator piston, which compresses the gas and increases damping.

Single-adjustable shocks have a knob that alters rebound characteristics. Double and triple adjustable shocks are available. Adjustments should always be made starting from the full-stiff position. Double- and triple-adjustable shocks should have the compression adjustment made, followed by the rebound adjustment.

Single-adjustable shocks have a knob that alters rebound characteristics. Double and triple adjustable shocks are available. Adjustments should always be made starting from the full-stiff position. Double- and triple-adjustable shocks should have the compression adjustment made, followed by the rebound adjustment.

RideTech’s 2-inch threaded body shocks are available with stroke lengths ranging from 2.9 to 6.9 inches. These are the single-adjustable versions.

RideTech’s 2-inch threaded body shocks are available with stroke lengths ranging from 2.9 to 6.9 inches. These are the single-adjustable versions.

To provide smooth movement throughout the range of travel and to accommodate minor misalignment of the attachment bolts, spherical bearings are used in the mounts of 2-inch body shocks.

To provide smooth movement throughout the range of travel and to accommodate minor misalignment of the attachment bolts, spherical bearings are used in the mounts of 2-inch body shocks.

Spacers for the spherical bearings are included to allow the use of either 1/2- or 5/8-inch mounting hardware.

Spacers for the spherical bearings are included to allow the use of either 1/2- or 5/8-inch mounting hardware.

These are the pieces used to install coil springs on threaded body shocks. The lower adjustment nut is on the left, the upper spring retainer on the right. The Delrin spring washers reduce the effort necessary to make preload adjustments.

These are the pieces used to install coil springs on threaded body shocks. The lower adjustment nut is on the left, the upper spring retainer on the right. The Delrin spring washers reduce the effort necessary to make preload adjustments.

The threaded lower spring retainer is used to adjust preload. Unlike most coilovers that use a second nut to secure the adjustment, RideTech uses a clean, simple pinch bolt.

The threaded lower spring retainer is used to adjust preload. Unlike most coilovers that use a second nut to secure the adjustment, RideTech uses a clean, simple pinch bolt.

Assembly of the coilovers begins with the installation of the lower adjustment nut.

Assembly of the coilovers begins with the installation of the lower adjustment nut.

The lower Delrin washer is installed and then the spring is slipped in place.

The lower Delrin washer is installed and then the spring is slipped in place.

Next, the upper Delrin bushing and the spring retainer is installed. This example is 0.50-inch thick, a dropped version that is 1.25 inches thick is available for installations that require more clearance for the upper mount.

Next, the upper Delrin bushing and the spring retainer is installed. This example is 0.50-inch thick, a dropped version that is 1.25 inches thick is available for installations that require more clearance for the upper mount.

Coilovers

No discussion of shocks would be complete without including coilovers. Basically a coil spring wrapped around a shock absorber, coilovers offer the ultimate in suspension flexibility. Coilover shocks are available with fixed or adjustable damping, spring pre-load is adjustable, and optimizing the spring rate is a simple matter of swapping coils.

When selecting coilovers there are a number of factors to consider, not the least of which is the space available. That will dictate the length of the complete unit and the diameter of the springs. In most cases independent suspension systems need 2-1/2 to 3 inches of compression stroke while solid axles will require 4 inches or more (motion ratio will explain the reason for the difference). RideTech suggests that the shocks have approximately 60 percent of their travel available at ride height to handle the worst bumps.

Choosing the right spring for coilovers is critical and that's often where things go wrong. Coilover springs are rated by the number of pounds required to compress them 1 inch, and there are a number of steps to determine the spring rate required. Obviously vehicle weight has to be considered, however the goal is to find "corner" or wheel weight rather than total weight. RideTech recommends using race car–style individual wheel scales to accomplish this. Another option is to "axle weigh" each end of the car and divide the results by two.

With the wheel weights established, the unsprung weight, or the weight of the components not supported by the springs, like the wheels, brakes, spindles, rear axle housing, half the suspension links (because one end is attached to the chassis and the other to the wheel), and similar parts, are deducted from the wheel weight to determine the sprung weight.

The next consideration is motion ratio. That is the mechanical advantage independent suspension control arms have on the springs. Control arms act like a lever that not only makes the springs easier to compress, it also means they don't compress as far as the wheel travels. The more leverage the control arms have on the springs, the higher the spring rate needs to be.

Finally, is the angle of the spring or coilover in relation to the control arms (or the solid axle is so equipped)? Typically, this measurement will fall somewhere between 70 and 90 degrees.

Armed with all the pertinent numbers there is an easy way to determine the spring rate required: Plug them into the spring rate calculator found on RideTech's website (ridetech.com). While that procedure is not complicated, for anyone who has questions and would like to talk with a live person to get them answered, the tech team stands ready and is just a phone call away. And, if finding the necessary scales to do the job turns out to be an obstacle or if the array of shocks is confusing, RideTech has accumulated data on a variety of cars and trucks that makes it possible to make specific recommendations for almost every application.

Recently we had the opportunity to give a Model A Ford and a 1934 Chevy the shock treatments they needed. The Model A had parts house shocks of some sort and as a result of totally inappropriate damping when driving through curves and encountering rough pavement the suspension would chatter, which made the car feel as though it was skipping around. In addition, the suspension was extremely stiff over small bumps and things like expansion strips and seams in the pavement.

To improve its road manners we decided to give a set of RideTech Q-series shocks a try and as soon as the last one was put in place we went for a drive. The difference in the Model A was immediately noticeable—the disconcerting cornering behavior was gone and the ride was improved in all respects. While these shocks lacked a rebound adjustment, in this case it wasn't needed.

Our subject Chevy was equipped with independent suspension fore and aft with coilovers and antiroll bars—all the ingredients for a great ride and outstanding handling. Unfortunately, the springs must have been spec'd for a Mack truck judging by the retina-separating ride. The coupe was particularly brutal on SoCal's concrete ribbons, it was stiff and choppy as a result of spring rates that were too high and poorly calibrated compression and rebound damping.

After weighing all four corners of the coupe and plugging the info into the RideTech calculator we ordered four single-adjustable HQ series shocks with the recommended springs. With the proper springs and the rebound damping dialed in, to say the improvement was dramatic is an understatement. The new combination made the Chevy seem like an entirely new car.

When it comes down to measuring ride quality there are a number of sophisticated methods to evaluate shocks and coilovers. In competitive applications you can rely on lap times, skid pad numbers, or other measurable forms of performance. But with street-driven cars the results are far more subjective, so the feedback we rely on most comes from the seat of our pants. The methodology may not be high tech but it's accurate (no pun intended). When the suspension components are right, you'll feel it there first. We sure did.

A wire snap ring locks the upper retainer in position.

A wire snap ring locks the upper retainer in position.

The adjuster is tightened to establish the specified installed length of the spring, which preloads the spring and pushes the retainer against the snap ring.

The adjuster is tightened to establish the specified installed length of the spring, which preloads the spring and pushes the retainer against the snap ring.

An assembled coilover ready for installation. Note the adjustment knob at the top for tuning rebound control.

An assembled coilover ready for installation. Note the adjustment knob at the top for tuning rebound control.

Individual electronic scales were used at each wheel of our subject Chevrolet. The 2,800-pound coupe was reasonable and well balanced.

Individual electronic scales were used at each wheel of our subject Chevrolet. The 2,800-pound coupe was reasonable and well balanced.

After entering all the data into the RideTech spring calculator, we found that all four corners should be fitted with 350-pound springs—shocks are single adjustable.

After entering all the data into the RideTech spring calculator, we found that all four corners should be fitted with 350-pound springs—shocks are single adjustable.

While weighing the car is the preferred method of establishing the required spring rate, RideTech has accumulated lots of data on cars and trucks that can be used as a guideline.

While weighing the car is the preferred method of establishing the required spring rate, RideTech has accumulated lots of data on cars and trucks that can be used as a guideline.

Part of the procedure to determine the motion ratio of an independent suspension is measuring the distance from the centerline of the control arm pivot point to the centerline of the ball joint.

Part of the procedure to determine the motion ratio of an independent suspension is measuring the distance from the centerline of the control arm pivot point to the centerline of the ball joint.

The next measurement is from the centerline of the control arm bushing to the point on the control arm directly under the center of the spring or the coilover assembly.

The next measurement is from the centerline of the control arm bushing to the point on the control arm directly under the center of the spring or the coilover assembly.

An angle finder was used to determine the amount the shocks leaned from vertical. In this case the angle was 13 degrees.

An angle finder was used to determine the amount the shocks leaned from vertical. In this case the angle was 13 degrees.

For a simple solution to the rough ride of a solid-axle Model A, we installed RideTech non-adjustable, smooth body shocks. They worked perfectly out of the box and no adjustments were needed.

For a simple solution to the rough ride of a solid-axle Model A, we installed RideTech non-adjustable, smooth body shocks. They worked perfectly out of the box and no adjustments were needed.

Included with the smooth-body shocks are mount bushings to accommodate common size mounting fasteners.

Included with the smooth-body shocks are mount bushings to accommodate common size mounting fasteners.

RideTech coilover springs are available in spring rates ranging from 125 to 800 lb/in. These springs are made in Indiana by HyperCo and come powdercoated and have a part number indicating the spring rate for easy identification.

RideTech coilover springs are available in spring rates ranging from 125 to 800 lb/in. These springs are made in Indiana by HyperCo and come powdercoated and have a part number indicating the spring rate for easy identification.

One of the many advantages of a mono-tube shock is the larger piston (left) when compared to the twin-tube style. The bigger piston provides superior fluid control and lower operating temperatures.

One of the many advantages of a mono-tube shock is the larger piston (left) when compared to the twin-tube style. The bigger piston provides superior fluid control and lower operating temperatures.