The rule of thumb is that you need at least 15 inches of engine vacuum to operate a power brake booster safely. With a heads-up driver and some caution you might run some boosters with even less engine vacuum. It really depends on the car, the brakes, the master cylinder, the booster, and how adept you are at anticipating the traffic ahead of you. But there is always some risk: You might not get enough brake boost in some panic situations. Our experience has been mixed. On the 620hp solid-roller 427ci small-block Chevy in our '75 Laguna, we get almost 8 inches of vacuum, and our vacuum booster seems pretty happy with that. The hydraulic-roller 400ci small-block in our 1968 Nova, however, makes almost 100 hp less, but it's maxed out at just 4 inches of vacuum at idle. The brake booster in the Nova works only about half the time—and then mostly at highway cruising speed. In clogged traffic or city driving, however, that vacuum booster is nothing but dead weight.

Today's radical street cams are great at making power, but let's face it—you are still on the hook for getting your street machine slowed down. If you need help in the braking department due to a big bumpstick (such as our Nova's), there are really only two solutions: convert to a manual brake booster (and lose all hope of easy footwork), or convert to some form of hydraulically assisted brake booster (and restore that light touch to your power brakes). We knew which fix we preferred.

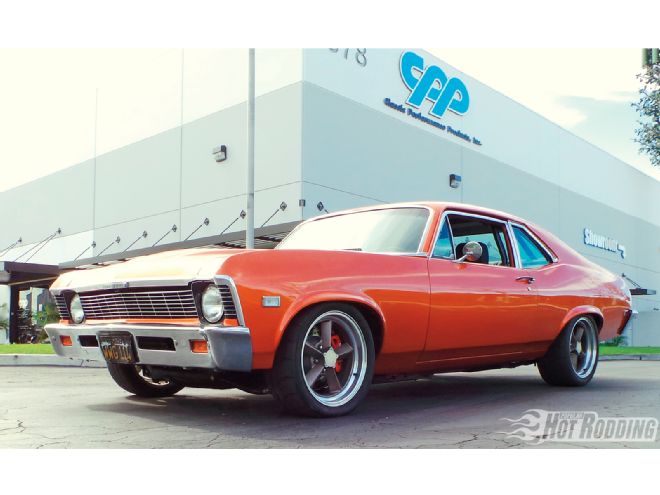

We were one of the first to try CPP’s new Hydra Stop system, taking our 1968 Nova project to CPP’s engineering lab at their new corporate headquarters in Placentia, California. CPP’s showroom is vast, and open to the public.

We were one of the first to try CPP’s new Hydra Stop system, taking our 1968 Nova project to CPP’s engineering lab at their new corporate headquarters in Placentia, California. CPP’s showroom is vast, and open to the public.

Hydraulic assist is not a new idea—it's been around on production vehicles for decades, and they are the solution of choice in applications where engine vacuum is not an option for assist. Diesels and turbochargers are the most common OEM powertrain pairings with hydraulically assisted brakes, and companies like Bosch have built millions of hydraulic assist brake boosters for use in OEM production. Late in 2013, however, Classic Performance Products (CPP) tapped into the vast tier-one OEM supply line to source a hydraulic brake assist unit that could be used on classic Chevys—the result being a complete line of Hydra Stop brake kits.

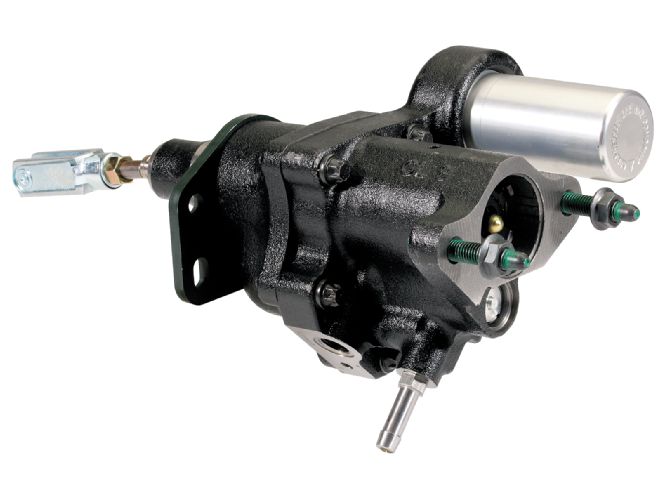

Like all hydraulic assisted brakes, CPP's Hydra Stop uses fluid pressure from the power steering system to assist in applying pressure to the master cylinder. Here's how it works. Normally, in the case of a vacuum booster, the pressure differential between two sides of a diaphragm is used to apply pressure to the master cylinder. When engine vacuum is low, the pressure differential is low, so stopping power is limited or even nonexistent. With a hydraulic assist unit, however, pressure from the power steering system is stored in an accumulator, and momentarily discharged to the master cylinder when brake pressure is applied. The beauty of a hydro assist is that pedal effort is low and stopping power is consistent, irrespective of the engine's load.

Hydra Stop is available in a couple of versions, including the “Show Stopper” ($899, 6474HBK-SB), which includes CPP’s polished aluminum MCPV-1 master cylinder (with integrated dual-adjustable prop valve and brake light switch), the Hydra Stop booster with a chrome-plated accumulator cover, billet aluminum baseplate, and a braided stainless hose/hardware kit.

Hydra Stop is available in a couple of versions, including the “Show Stopper” ($899, 6474HBK-SB), which includes CPP’s polished aluminum MCPV-1 master cylinder (with integrated dual-adjustable prop valve and brake light switch), the Hydra Stop booster with a chrome-plated accumulator cover, billet aluminum baseplate, and a braided stainless hose/hardware kit.

CPP saw a broad potential market with Bosch's existing OEM hydraulic assist technology; the challenge was adapting it to a variety of classic cars (Chevys first) and getting the price into regular-guy territory. As we shall see with PHR's Project Nova, CPP has succeeded in doing both!

Recognizing the fact that hydro-assisted brakes are not a one-size-fits-all solution, CPP got busy designing kits and supporting hardware for a variety of needs and budgets. At the top of the heap is the Show Stopper system (PN 6474HBK-SB, $899) which features CPP's polished aluminum MCPV-1 master cylinder (a breakthrough product in its own right), the hydraulic booster Hydra Stop assembly with matching chrome accumulator cover, billet aluminum firewall mounting bracket, and a kit with all hoses and hardware. For a little less at $749, you can get the Street Beast kit (PN 6474HBK-BSB) that includes an aluminum Corvette master cylinder, side-mounted proportioning valve, and a hose/hardware kit. While not as dressy as the Show Stopper, the Street Beast is nearly as functional, but at a lower price point. It's worth noting, however, that the MCPV-1 master cylinder in the Show Stopper system includes an integral proportioning valve and brake light switch. (The prop valve on the MCPV-1 is a double-adjustable type, giving you not only control over rear brake bias, but allowing control over the rear brake's max pressure.) From there, you can buy individual pieces, such as the Street Beast hydraulic assist booster, for $389 (PN 6474BHK-BSB). It's possible to mix and match CPP's Hydra Stop components a la carte with CPP's line of steering boxes, power steering pumps, and various brake systems, and that's just what we did with our Nova.

You may recall back in the July 2011 issue (see "Disco Tech"), we installed CPP's 13-inch dual-piston brakes in the front and their 12-inch single-piston brakes in the rear, along with CPP's 11-inch booster/master cylinder combo. With everything all plumbed up and working fine (other than the high pedal effort), we saw no need to re-plumb and bleed the brakes again when we had a perfectly serviceable master cylinder and prop valve. The solution? Just get the Street Beast hydro assist ($389) and the hose kit ($115, PN HAHK-R). We'd save some money, and make the installation a lot easier by not having to redo or bleed the brake lines. We're guessing many readers would be in the same situation, so we took a cost-saving shortcut by unbolting the master cylinder and zip-tying it away from our booster swap. All together, we spent about $530, which also included a small inline filter ($20, PN 20-0038F) for the low-pressure return line of the booster.

CPP sells the Street Beast Hydra Stop booster as a stand-alone piece for $389 (PN 6474BHK-BSB) for guys who already have a master cylinder they want to keep. This also saves time plumbing new brake lines and/or bleeding your system. Our Nova was the trial to see if this move was practical, and as we found out, it certainly is. The only other thing you’ll need from CPP is the hose/hardware kit for $115 (PN HAHK-R).

CPP sells the Street Beast Hydra Stop booster as a stand-alone piece for $389 (PN 6474BHK-BSB) for guys who already have a master cylinder they want to keep. This also saves time plumbing new brake lines and/or bleeding your system. Our Nova was the trial to see if this move was practical, and as we found out, it certainly is. The only other thing you’ll need from CPP is the hose/hardware kit for $115 (PN HAHK-R).

The results were immediate and dramatic. In before/after testing, we got the same 60-0 stopping distance of 120 feet, but the difference in pedal effort was astonishing. We went from cranking all the pedal pressure we could muster, to using just light-to-moderate force. In traffic, we can now relax, knowing that even panic stops are easy at any engine load, speed, or rpm. This is one mod that really gives the green light to big cams and big power on the street!

More Video Online!

We captured the entire CPP Hydra Stop installation in-depth in a 16-minute video. Check out CPP's new building, their R&D shop, the final test, and a bunch of other things we didn't have the room to show you here! Go to our YouTube channel (YouTube.com/PopularHotRodding) and look for "CPP Hydra Stop Brake Booster."

1. Our Nova’s 400ci small-block made 523 hp on the engine dyno, but it only builds a measly 4 inches of vacuum to feed the power brake booster. That’s not enough to stop safely, so when CPP’s Hydra Stop came out, we wanted to be the first to test it.

1. Our Nova’s 400ci small-block made 523 hp on the engine dyno, but it only builds a measly 4 inches of vacuum to feed the power brake booster. That’s not enough to stop safely, so when CPP’s Hydra Stop came out, we wanted to be the first to test it.

2. As a starting point, you’ll need to remove your brake booster to make room for the Hydra Stop. In this side-by-side view, we are comparing the diameters of the booster bases, since this is the part that passes through the hole in the firewall bulkhead. The Hydra Stop is about a quarter-inch larger in diameter, so the firewall hole will need to be enlarged.

2. As a starting point, you’ll need to remove your brake booster to make room for the Hydra Stop. In this side-by-side view, we are comparing the diameters of the booster bases, since this is the part that passes through the hole in the firewall bulkhead. The Hydra Stop is about a quarter-inch larger in diameter, so the firewall hole will need to be enlarged.

3. Some tape on the firewall and a marker outline for the larger hole can be used as a guide for enlarging the booster hole. A die grinder was used to gradually sneak up on the right size, with the new Hydra Stop being used to trial fit during the progress.

3. Some tape on the firewall and a marker outline for the larger hole can be used as a guide for enlarging the booster hole. A die grinder was used to gradually sneak up on the right size, with the new Hydra Stop being used to trial fit during the progress.

4. A 9/16-inch wrench is used to snug the four nuts holding the Hydra Stop to the firewall studs. Note how our original master cylinder (with brake lines still attached) is being held safely out of the way with zip ties while the Hydra Stop booster installation is completed. Our newer master cylinder was perfectly serviceable, and we didn’t want to re-bleed our brake system, so we saved some time and money here.

4. A 9/16-inch wrench is used to snug the four nuts holding the Hydra Stop to the firewall studs. Note how our original master cylinder (with brake lines still attached) is being held safely out of the way with zip ties while the Hydra Stop booster installation is completed. Our newer master cylinder was perfectly serviceable, and we didn’t want to re-bleed our brake system, so we saved some time and money here.

5. A look up into the footwell of the driving position shows that the adjustable clevis fork has been shortened to length (it’s on a threaded rod for pedal height adjustment), and attached to the upper hole in the brake pedal (the one usually reserved for manual brakes). This keeps the booster rod directly in line with the Hydra Stop and provides the right leverage for the unit. You will also need to readjust the brake stoplight switch (foreground) to disengage properly at the new pedal height.

5. A look up into the footwell of the driving position shows that the adjustable clevis fork has been shortened to length (it’s on a threaded rod for pedal height adjustment), and attached to the upper hole in the brake pedal (the one usually reserved for manual brakes). This keeps the booster rod directly in line with the Hydra Stop and provides the right leverage for the unit. You will also need to readjust the brake stoplight switch (foreground) to disengage properly at the new pedal height.

6. Back in the engine bay, the original power steering hoses are disconnected from the steering box, and these new -6 AN fittings are installed on the box (the 11/16-inch high-pressure feed and ⅜-inch low-pressure return both get converted to -6). These fittings are included in the $115 hose kit.

6. Back in the engine bay, the original power steering hoses are disconnected from the steering box, and these new -6 AN fittings are installed on the box (the 11/16-inch high-pressure feed and ⅜-inch low-pressure return both get converted to -6). These fittings are included in the $115 hose kit.

7. CPP’s hose kit comes with all the lines and fittings you’ll need for a complete installation. The high-pressure lines already come with one fitting installed on one side—you just need to measure and cut the other end of each line. Here a cutoff wheel is used after measuring out the needed length. In this case, the line that runs from the Hydra Stop discharge to the steering box input is being made.

7. CPP’s hose kit comes with all the lines and fittings you’ll need for a complete installation. The high-pressure lines already come with one fitting installed on one side—you just need to measure and cut the other end of each line. Here a cutoff wheel is used after measuring out the needed length. In this case, the line that runs from the Hydra Stop discharge to the steering box input is being made.

8. The high-pressure fitting consists of two parts—an inner and outer. The hose needs to be gradually screwed into the outer fitting in counterclockwise motion (it’s reverse threaded inside the fitting). When the hose bottoms out on the fitting, it’s time to lube the inner fitting and screw that in (see next photo for finished hose end). The two fittings act as a wedge or a clamp to seal the hose against pressure that will reach 1,500 psi.

8. The high-pressure fitting consists of two parts—an inner and outer. The hose needs to be gradually screwed into the outer fitting in counterclockwise motion (it’s reverse threaded inside the fitting). When the hose bottoms out on the fitting, it’s time to lube the inner fitting and screw that in (see next photo for finished hose end). The two fittings act as a wedge or a clamp to seal the hose against pressure that will reach 1,500 psi.

9. The finished hose is barely a foot long, but its flexibility will be put to use as it will twist around the Hydra Stop and enter the steering box near the firewall. How you elect to clock the 90-degree fitting ends will matter, so some trial fitting (and loosening and tightening of one end) may be necessary.

9. The finished hose is barely a foot long, but its flexibility will be put to use as it will twist around the Hydra Stop and enter the steering box near the firewall. How you elect to clock the 90-degree fitting ends will matter, so some trial fitting (and loosening and tightening of one end) may be necessary.

10. Here, all our lines that plumb the Hydra Stop have been completed. With the master cylinder held out of the way, you can see most of what’s going on: The high-pressure line coming off the back of the steering pump now goes directly into the Hydra Stop inlet, seen on the right side below the accumulator. On the left side of the Hydra Stop, a high-pressure line runs to the steering box inlet side. That other outlet line on the Hydra Stop is a low-pressure line that returns to the power steering pump reservoir. (More on that later.) What’s important to know is that once the accumulator is charged, there is no load on the pump—you won’t even know it’s charging it happens so quick. When the accumulator does discharge under braking, it’s very brief, low in volume, and short in duration.

10. Here, all our lines that plumb the Hydra Stop have been completed. With the master cylinder held out of the way, you can see most of what’s going on: The high-pressure line coming off the back of the steering pump now goes directly into the Hydra Stop inlet, seen on the right side below the accumulator. On the left side of the Hydra Stop, a high-pressure line runs to the steering box inlet side. That other outlet line on the Hydra Stop is a low-pressure line that returns to the power steering pump reservoir. (More on that later.) What’s important to know is that once the accumulator is charged, there is no load on the pump—you won’t even know it’s charging it happens so quick. When the accumulator does discharge under braking, it’s very brief, low in volume, and short in duration.

11. The CPP Hydra Stop kit includes this T-fitting to join and combine the low-pressure returns from the Hydra Stop booster and the steering box. That will work fine, but the folks at CPP wanted to experiment with something new—a power steering pump reservoir with dual low-pressure returns . . .

11. The CPP Hydra Stop kit includes this T-fitting to join and combine the low-pressure returns from the Hydra Stop booster and the steering box. That will work fine, but the folks at CPP wanted to experiment with something new—a power steering pump reservoir with dual low-pressure returns . . .

12. CPP also manufactures their own power steering pumps and reservoirs. They aren’t rebuilt units, but brand-new ones. (Our original pump is on the left. Note the single low-pressure return). The new CPP pump is on the right, and the reservoir has two return lines to make installation of the Hydra Stop easier, and to tidy up the engine bay. No word yet if this is available to the public, but CPP has a long history of bringing cool stuff like this to market.

12. CPP also manufactures their own power steering pumps and reservoirs. They aren’t rebuilt units, but brand-new ones. (Our original pump is on the left. Note the single low-pressure return). The new CPP pump is on the right, and the reservoir has two return lines to make installation of the Hydra Stop easier, and to tidy up the engine bay. No word yet if this is available to the public, but CPP has a long history of bringing cool stuff like this to market.

13. Here’s what the plumbing looks like at the pump—the high-pressure feed line is on top, and the two low-pressure return lines are on the bottom. Note how one of the return lines is pulled away from the header pipe with an Adel clamp, leaving room for some engine twist. The other return line is zip tied to the first.

13. Here’s what the plumbing looks like at the pump—the high-pressure feed line is on top, and the two low-pressure return lines are on the bottom. Note how one of the return lines is pulled away from the header pipe with an Adel clamp, leaving room for some engine twist. The other return line is zip tied to the first.

14. Now it’s time to finally bolt the master cylinder to the Hydra Stop booster. It’s cool that the brake lines haven’t even been touched, and all work could be accomplished with the master still in place. Note that the angle of the Hydra Stop brings the master cylinder down where the dipstick tube was. The dipstick tube needed a slight bend to clear the master—an easy fix.

14. Now it’s time to finally bolt the master cylinder to the Hydra Stop booster. It’s cool that the brake lines haven’t even been touched, and all work could be accomplished with the master still in place. Note that the angle of the Hydra Stop brings the master cylinder down where the dipstick tube was. The dipstick tube needed a slight bend to clear the master—an easy fix.

15. You’ll need to fill and top off the power steering system to where there is no longer any air in the Hydra Stop/steering box/steering pump circuit, which can take a while. A “driver” is needed to operate the steering back and forth, while occasionally pumping the brake pedal. You’ll hear a menagerie of sounds until the air gets worked out. The main thing is to keep topping off the reservoir. During your first testdrive, keep a bottle of power steering fluid handy—you’ll need to top it off when the level goes down.

15. You’ll need to fill and top off the power steering system to where there is no longer any air in the Hydra Stop/steering box/steering pump circuit, which can take a while. A “driver” is needed to operate the steering back and forth, while occasionally pumping the brake pedal. You’ll hear a menagerie of sounds until the air gets worked out. The main thing is to keep topping off the reservoir. During your first testdrive, keep a bottle of power steering fluid handy—you’ll need to top it off when the level goes down.

16. CPP’s Street Beast Hydra Stop looks snazzy under the hood of our ’68 Nova, but the real news is how easy the brakes work. Driving in traffic is no longer a prayer vigil—we can make panic stops when idiots cut in front or slam on the brakes, and the Nova just handles it with ease!

16. CPP’s Street Beast Hydra Stop looks snazzy under the hood of our ’68 Nova, but the real news is how easy the brakes work. Driving in traffic is no longer a prayer vigil—we can make panic stops when idiots cut in front or slam on the brakes, and the Nova just handles it with ease!