In the past we've shown how to build a small-block Chevy engine from the ground up. This time around we changed our focus a bit and think about those of us who are a bit less mechanically inclined or don't have the time or motivation to build a motor. The change of heart comes from us trying to put together an engine in a reasonable amount of time.

We've built engines a time or two in our lives and let us tell you, it's not always a walk in the park. Simply slip up and install a piston backwards or adjust a rocker or two too tight and bang, messed up engine and, missed magazine deadline. Building an engine from scratch often requires specialty tools to do the job correctly as well. Buy a special tool here, a special tool there, and heck, after a while you might as well have purchased a short block. But we digress.

In this particular case we decided to follow our own advice and opt for a crate engine rather than rebuilding what we had on hand. As we searched all our usual suppliers' wares for the best bang for our buck we just happened to come across the website of Blue Print Engines. Riz recognized 'em right off the bat and had actually used a couple of their remanufactured OEM replacement engines years ago (under the company's original Marshall Engine name) with great success.

So, with this in mind we turned to BluePrint Engines' website www.blueprintengines.com to see what they are currently offering in terms of small-block Chevys. What we discovered was that not only did they have a large selection of small-block Chevys from mild to wild, but their pricing was extremely reasonable as well. With our budget in mind we looked for something that would have adequate power and reliability – and what we found fit the bill perfectly! The small-block we ended up choosing was one of their fully dressed 355ci base performance engines (model BP35512CTC1).

The 35512CTC1 comes complete with a pair of the company's proprietary (designed and produced by BluePrint Engines) Muscle Series aluminum cylinder heads (1986 and earlier intake bolt pattern). The Muscle Series heads were designed by BluePrint to optimize the Chevy reciprocating assembly and are equipped with hardened retainers and springs, 195cc intake/75cc exhaust runners, 64cc combustion chambers, 2.02 swirl-polished intake and 1.60 exhaust valves (by the way, the heads are available on their own as part number H8002K too) a satin finish aluminum dual-plane intake, and a 650-cfm electric-choke carburetor. The seasoned blocks are four-bolt main, one-piece rear main seal, passenger-side dipstick configuration units. All blocks feature align-honed main bearing bores; the cylinders are honed on a computer-controlled machine to within .0002 straightness and roundness, and each cylinder sonic tested for thickness.

The bottom ends are assembled using Chevy heavy-beam rods with 150,000 PSI bolts, hypereutectic pistons fitted with Hastings moly rings, a flat-tappet cam (.480 intake, .486 exhaust, 229 intake/230 exhaust duration @ .050), a BluePrint premium cast steel crank, a Melling high-volume oil pump, and a heavy-duty double roller timing set. The icing on the cake with these BluePrint BP35512CTC1 engine assemblies is that they come with new chromed steel valve covers and timing cover, a new oil pan, and an HEI distributor. Plus each one is run on the dyno (test results are supplied with each engine) and come with 30 month/50,000 mile warranties. And saving the best feature of these babies for last – they retail for an unbelievable $3,695!

To back up our muscular BluePrint 355 we chose to use the time-tested TH350 transmission. For this we turned to our dog-eared Summit Racing catalog where we found the perfect match in their Summit-branded remanufactured, manual downshift valvebody equipped TH350 (part number SUM-700300). These babies are another budget-minded item that are perfect for the cash-conscious builder. Summit contracts their independent rebuilders to refurbish these trannies with all-new clutches, seals, gaskets, bushings, thrust washers, Kevlar bands, and brand new separator plates, and remanufactured pumps. You can't beat 'em for under $700 with no core charge!

We added a Summit Racing torque converter (1,900-2,300-rpm stall, part number SUM-G2700-1) and external-balance 168-tooth flex plate (part number SUMG104SFI) to round out our assembly, all for under $4,500. Not bad at all for fresh, new, muscular motorvation for a low-buck classic truck project. So take a look as we slide our new engine/trans combo between the rails of our project square body.

1. The first thing we did was check the engine out for shipping damage, but no damage was found. Next we bolted the Summit Racing flex plate on the rear of the crank. We made sure to torque the bolts to spec and use some red thread sealant for added protection.

1. The first thing we did was check the engine out for shipping damage, but no damage was found. Next we bolted the Summit Racing flex plate on the rear of the crank. We made sure to torque the bolts to spec and use some red thread sealant for added protection.

2. Next the Summit Racing TH350 was removed from its shipping crate and checked out for shipping damage. Good news – the trans looked great, especially with the fresh coat of black paint.

2. Next the Summit Racing TH350 was removed from its shipping crate and checked out for shipping damage. Good news – the trans looked great, especially with the fresh coat of black paint.

3. The torque converter was also inspected for leaks with none found.

3. The torque converter was also inspected for leaks with none found.

4. Make sure that you measure the torque converter gap after it is installed to the transmission. With a straight edge on the transmission to engine surface and a digital caliper we measured the gap of the torque converter. If the converter is too tight or too close to the engine you might not have installed the torque converter all the way into the transmission. If so, try installing the torque converter again while giving it a slight turn.

4. Make sure that you measure the torque converter gap after it is installed to the transmission. With a straight edge on the transmission to engine surface and a digital caliper we measured the gap of the torque converter. If the converter is too tight or too close to the engine you might not have installed the torque converter all the way into the transmission. If so, try installing the torque converter again while giving it a slight turn.

5. AMSOIL makes a really great ATF for our TH350. After I measure the torque converter I like to remove it and add a quart of ATF to prime the torque converter.

5. AMSOIL makes a really great ATF for our TH350. After I measure the torque converter I like to remove it and add a quart of ATF to prime the torque converter.

6. The snout on the torque converter has two inverted tangs that slip into a grove inside the transmission.

6. The snout on the torque converter has two inverted tangs that slip into a grove inside the transmission.

7. The engine and transmission should slide together with no binding. Make sure to measure the size of the pilot bearing on the engine and transmission input shaft. I've seen the incorrect pilot bearing from a manual transmission cause transmission issues with an automatic.

7. The engine and transmission should slide together with no binding. Make sure to measure the size of the pilot bearing on the engine and transmission input shaft. I've seen the incorrect pilot bearing from a manual transmission cause transmission issues with an automatic.

8. The flex plate and the torque converter are then mated after the transmission is bolted to the engine.

8. The flex plate and the torque converter are then mated after the transmission is bolted to the engine.

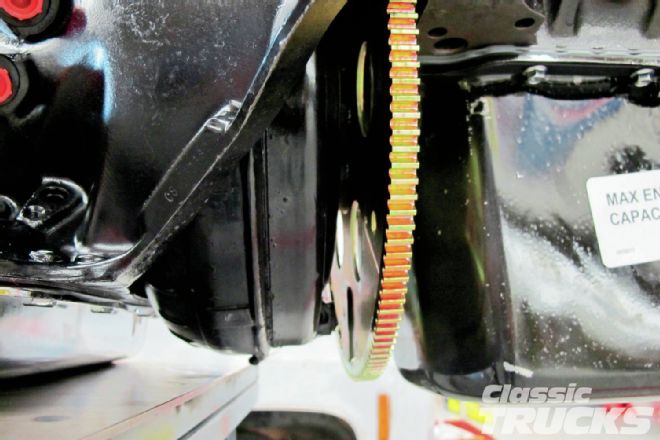

9. With the transmission bolted up to the engine we were able slide the whole assembly into our project truck. We made sure the stock transmission crossmember was removed before trying to stuff the engine transmission combo in.

9. With the transmission bolted up to the engine we were able slide the whole assembly into our project truck. We made sure the stock transmission crossmember was removed before trying to stuff the engine transmission combo in.

10. We chose to reuse the stock engine mounts because they were in good shape. This style engine mount is referred to as a clamshell and are, for some odd reason, hard to find replacements for anywhere other than the dealer.

10. We chose to reuse the stock engine mounts because they were in good shape. This style engine mount is referred to as a clamshell and are, for some odd reason, hard to find replacements for anywhere other than the dealer.

11. Another thing to think about is using a CPP transmission crossmember so that dual exhaust can be used.

11. Another thing to think about is using a CPP transmission crossmember so that dual exhaust can be used.

12. An electric choke-equipped Holley 600-cfm carb came as part of the BluePrint engine package. Our BluePrint engine also came with an HEI-style distributor that was timed to specs (34 degrees @ 4,000 rpm). How cool is that?

12. An electric choke-equipped Holley 600-cfm carb came as part of the BluePrint engine package. Our BluePrint engine also came with an HEI-style distributor that was timed to specs (34 degrees @ 4,000 rpm). How cool is that?

One High-Performance Crate Engine at a Time

BluePrint Engines started 20 years ago in a small garage in Central Nebraska. What started as a passion for speed turned into a hobby, then a job, and finally a career. Its founder built one engine at a time for his friends and neighbors, and bit by bit his business and reputation grew. Drag racers, circle track racers, classic truckers, and street rodders all got some of the first engines produced by BluePrint Engines. Most of us can relate to what happened next. Babies, mortgages, and a need for financial security drove BluePrint's founder into the mainstream. Grocery-getters were easier to sell to a LOT more people. His success in that endeavour is also legendary. Today the company he founded has produced over 200,000 factory replacement engines for cars and light trucks as well as their popular performance street engines like the one we've chosen for our 1979 C10.