The only performance-oriented Pontiac V-8 ever fitted with electronic fuel metering was the turbocharged 301 and T/A 4.9 of the early ’80s. An onboard computer was fed information from several sensors located throughout the vehicle. It was processed and used to control a special electronic solenoid found within the Quadrajet carburetor that continually adjusted its primary metering rods’ position in their jets, thereby improving economy and seemingly maximizing performance in a given operating condition.

Though the system was rather effective, its efficiency wasn’t akin to that of electronic fuel injection (EFI). Where air passing through the carburetor must draw fuel from the float bowl, atomizing it in the process, the fuel within an injected system is under continuous pressurization and is delivered in a finely atomized mist no matter the temperature or operating condition. It’s this ability that allows an EFI-equipped engine to idle and operate so much more efficiently at initial startup and during the time it takes the engine to reach its normal operating temperature.

During full-throttle conditions when airflow is greatest, carburetors are quite effective. In fact, performance typically doesn’t vary greatly when comparing a properly calibrated carburetor to an EFI system on the dyno or dragstrip. EFI’s effectiveness elsewhere, however, makes it attractive to hobbyists. Retrofitting a vintage V-8 with EFI has historically been a difficult task, as the components had to be properly sized and/or calibrated for the exact application, and the tuning required to achieve smooth driveability and performance in all conditions seemingly required training just short of a quantum physicist.

When discussing the positive effects EFI can have on cold startup and driveability, Lou Rotella was immediately interested in adding such a system to his ’67 Firebird. When compared to other modern fuel-injected cars in his garage, the Firebird’s 455 is a bit cold blooded and requires additional warm-up time in cool weather operation, even with a properly calibrated Quadrajet fitted with an electric choke. He explained how he’s grown accustom to the start-up-and-go characteristics associated with EFI vehicles, and dislikes the excessive cranking and pumping that’s often required when the fuel in the carburetor’s float bowl evaporates after sitting for extended periods. He asked that we locate and install a system that would work well for his Firebird.

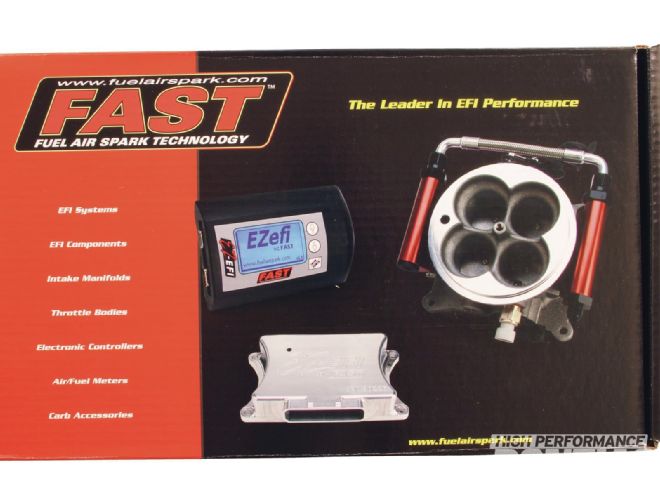

Fuel Air Spark Technology (FAST) has gained the reputation as an EFI industry leader, offering top-quality components and complete systems for myriad applications. In 2009 it introduced its line of EZ-EFI kits for street rods and musclecars, featuring fuel injectors fitted to a throttle body that mimics the shape and appearance of a 4150-type carburetor. It also features a self-tuning computer that requires minimal input for initial startup and contains the ability to continually monitor and adjust the fuel mixture of a given engine to deliver maximum performance in every possible operating condition.

We immediately recognized from its benefits and attributes that FAST’s EZ-EFI may be a great solution for Lou’s Firebird. Further investigation revealed that the self-contained kit is ideal for engines up to 500 ci producing as much as 600 hp and generating at least 8 inches of manifold vacuum at idle. It seemed ideal for the 455, so we contacted FAST and placed an order for PN 30227-KIT, which contains the base EZ-EFI system, as well as an inline electric fuel pump and all the associated components for installation. The kit arrived on our doorstep within a few days and we began planning the installation process.

Due to space and time constraints, it wasn’t feasible that we install the EZ-EFI system in our home garage, so we sought the experience and expertise of Tim Pokorski at T&M Automotive in Omaha, Nebraska, to handle the task. T&M specializes in restoring, repairing, and modifying pre-’80 vehicles and has worked with similar EFI kits before. Tim was confident his team could install the EFI system quickly and easily and assigned Senior Technician (and nephew) Dave Pokorski to the project.

Follow along as we document and detail the EZ-EFI installation process onto the Firebird. FAST suggests it takes several hours to install when using the supplied components, and we’re confident that the average hobbyist can complete the task working several nights in their home garage during the week and/or over a weekend.

In next month’s issue, we will discuss the steps required for initial startup and compare its driveability and performance on the street and chassis dyno.

[1] This ’67 Firebird convertible was restored with the intent of driving it regularly. Its original 400 is in storage and a mildly modified 455 sits in its place. Since user-friendliness is a high priority for owner Lou Rotella, it proved an ideal candidate for a retrofit fuel-injection system.

[2] The Firebird’s 455 was assembled several years ago and contains forged Speed Pro pistons in 0.030-inch overbore, stock cast rods, and a stock-stroke nodular cast-iron crankshaft. The 400-spec 4X cylinder heads produce a compression ratio around 9.7:1 and flow about 230 cfm at 28 inches of pressure. Since its Edelbrock Performer RPM intake manifold accepts square-bore and spread-bore carburetors, installing a throttle-body fuel injection kit in place of the Quadrajet should present minimal issues.

[3] The EZ-EFI fuel-injection system from FAST is a complete self-tuning kit that uses a compact throttle-body and fits anywhere a traditional square-bore carburetor will. PN 30227-KIT contains all the necessary components for relatively easy installation, including those for fuel delivery, and retails for about $2,200. Professionals agree that it requires minimal tuning know-how for immediate startup and excellent performance.

[4] The EZ-EFI throttle body is constructed of cast aluminum. It contains four proprietary fuel injectors that deliver up to 88 pounds of fuel per hour at 60 pounds of fuel pressure. The throttle body also houses such critical system electronics as the manifold absolute pressure (MAP), air temperature and throttle position sensors, as well as the idle control motor. The system is covered by a limited lifetime warranty, and FAST uses readily available GM components, which are widely available.

[5] Mimicking a 4150-type four-barrel carb, the EZ-EFI throttle body contains four 1.75-inch-diameter throttle blades that deliver more than 1,000 cfm at 20.4 inches of water pressure. That’s substantially more than a carburetor with comparably sized bores because there’s no fuel-feeding booster rings to impede airflow. Since a throttle body doesn’t require high-velocity airflow for proper booster signal, it can also be made larger without adverse effects.

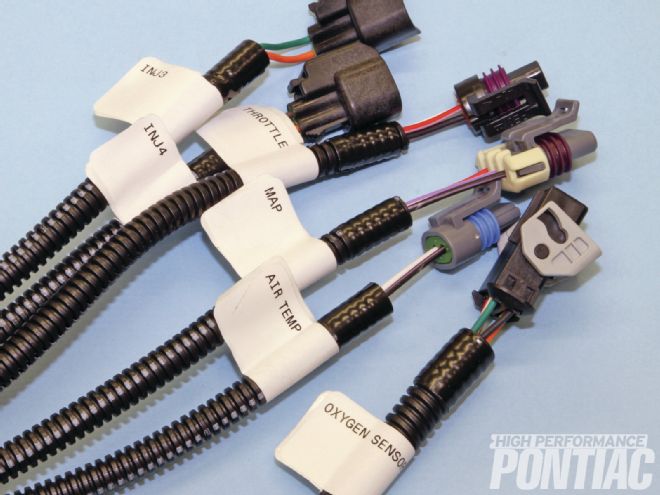

[6] The EZ-EFI kit contains all of the necessary electrical components and connections for complete installation. That includes a main wiring harness, a serial cable for connecting the handheld controller, and a plug-in power lead for a 12V source within the vehicle.

[7] T&M Automotive in Omaha, Nebraska, was enlisted to perform the EFI install. We worked with Senior Technician Dave Pokorski to complete the process. He begins by removing the Quadrajet, its mechanical fuel pump, and the intermediate fuel line. We sourced a fuel-pump block-off plate and he installed it in place of the pump.

[8] The engine control unit (ECU) is the self-tuning system’s brain. Water-tight and temperature-resistant, it can be mounted underhood or inside the vehicle.

[9] FAST recommends keeping it at least 2 feet away from electrically noisy components, such as an ignition coil and/or control box. We mounted ours in the Firebird’s glovebox, which also provides quick and easy access when using the handheld controller for initial startup, and any monitoring that might be necessary during normal driving.

[10] Dave drilled a 1.375-inch hole through the firewall and fed the wiring harness through. A rubber grommet was then used to reduce the diameter of the hole to provide a tighter seal.

[11] FAST supplies the appropriate hardware and gasket required for throttle body installation. Dave threaded the studs into the carburetor flange on the intake manifold, installed the gasket, and set the EZ-EFI throttle body in place. He tightened the nuts securing the throttle body to the manifold to 10 ft-lb using a 1⁄2-inch socket.

[12] Each connection within the main wiring harness is clearly labeled for quick and easy identification and installation.

[13] Dave routes the wires as closely together as possible to remove any chance of them interfering with other components and to provide a visually clean installation.

[14] The ECU uses a number of sensors to adjust fueling, and this one measures coolant temperature. FAST supplies a fitting with 1⁄2-inch NPT threads, which allows easy installation into the coolant crossover of a typical Pontiac intake manifold or in the cylinder head of any casting produced from ’72 forward. Dave chose the intake manifold, as it’s easily accessible and requires minimal coolant system draining.

[15] A single wideband oxygen sensor mounted in the exhaust system measures the air/fuel ratio at every engine speed and operating condition. FAST recommends installing the sensor no closer than 20 inches from the nearest cylinder-head exhaust port to prevent heat damage, and at an angle at least 10 degrees from horizontal to prevent moisture damage. Dave found this area of the header collector ideal for installation. He will drill a 3⁄4-inch-diameter hole and weld the supplied bung into place. The oxygen sensor threads will be coated with antiseize before threading it into place and tightening to about 30 ft-lb using a 7⁄8-inch wrench.

[16] The EZ-EFI system is compatible with most any electronic ignition system and it uses RPM signal to determine fueling calculations. FAST recommends an aftermarket ignition control box, but it’s certainly not required. When using an HEI distributor, FAST supplies an RPM module, which is connected to the negative side of the coil (arrow) and provides the ECU with a clean RPM signal. Refer to the instructions to determine what’s required for your application. (We fixed the wire connector on the right as well.)

[17] With the electrical connections nearly complete, Dave addresses the fuel system next. The EZ-EFI system requires an adequate volume and pressure for proper operation. After completely draining the tank of any remaining fuel, he removes the Firebird’s tank to access its sending unit. He first disconnects the rubber fuel hoses and flexible neck coupling, and then uses a 9⁄16-inch socket to remove the nuts that secure the tank straps to the body. The tank then drops out. Use every precaution around any empty tank as the gasoline fumes are extremely flammable!

[18] FAST recommends that the entire fuel system be comprised of 3⁄8-inch-diameter fuel line to adequately supply the injectors and efficiently return excess fuel to the tank. The Firebird’s stock supply line measures 3⁄8-inch and is in good shape. The return line shown here measures just 5⁄16-inch, however.

[19] Dave removed the original return line from the sending unit and modified it to accept a 3⁄8-inch line that he fabricated. He soldered in place and coated it with fuel-resistant epoxy to permanently prevent leaks.

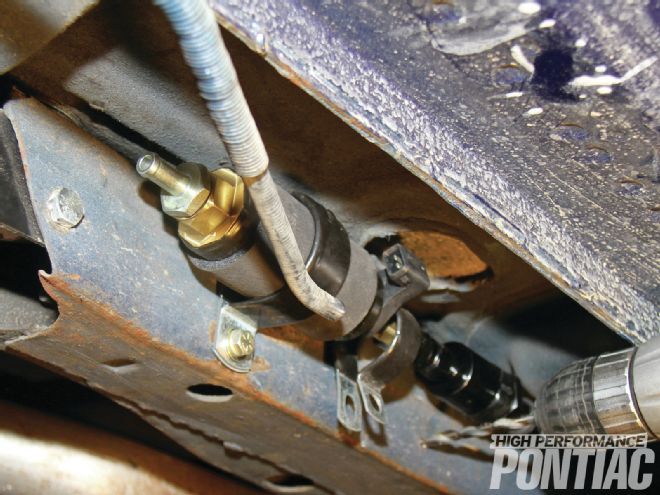

[20] PN 30227-KIT includes an inline electric fuel pump that flows 240 lph at 43.5 psi and contains an internal pre-filter, a post-pump filter, and all associated wiring and hardware for proper installation. FAST recommends installing the pump close to the tank and at a point below it to allow gravity feeding. Dave chose the passenger side framerail, which also allows him to reuse a portion of the original 3⁄8-inch supply line.

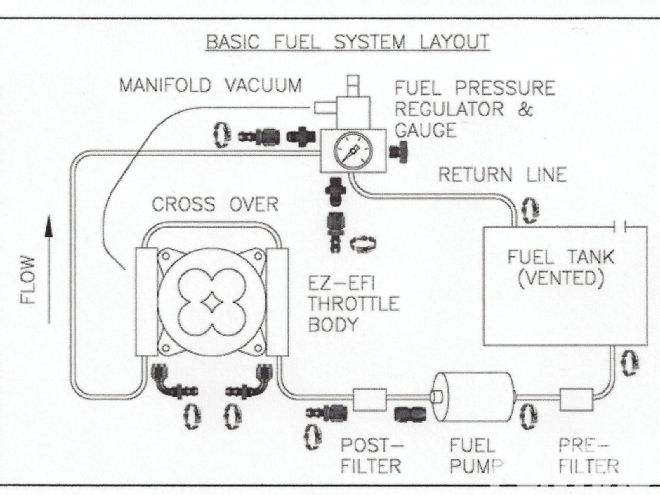

[21] He then connected the fuel pump to the main wiring harness and grounded it appropriately. Here’s the system’s diagram.

[22] A 25-foot-length fuel-injection-spec rubber hose that is compatible with low-grade ethanol-blend fuel (E15 or less), and several connectors are also included with PN 30227-KIT. The hose is completely adequate for use as a supply and/or return line. However, we prefer using hard fuel lines wherever applicable for durability and visibility, so Dave custom-bent and routed a 3⁄8-inch supply line from the pump and a 3⁄8-inch return line that run parallel to one another.

[23] Both line ends are near each other under the hood…

[24] … and near the tank. The fuel line mods add several hours to the process, so if time and/or easy installation is important to you, using the supplied hose is much simpler. With the fuel line modifications complete, Dave reinstalls the fuel tank at this time.

[25] With its EZ-EFI kit, FAST supplies a high-quality fuel-pressure regulator that uses a combination of mechanical spring pressure with vacuum assistance to maintain a setting of 43 psi. FAST recommends mounting it in the fuel system after the throttle body to ensure the injectors see constant volume and pressure. Dave fabricated a small bracket and mounted the regulator to the front of the passenger-side cylinder head, where it’s easily accessible for adjustment.

[26] Since the FAST fuel-injection system is a pass-through design, either fuel rail can be used as the supply or return. On our particular Firebird, Dave selected the throttle body’s rear fuel rail as the inlet and custom-bent a 3⁄8-inch supply line that’s connected to the main supply line using a short length of rubber hose. The front fuel rail connects to the regulator with a short length of hose. The regulator is then connected to the main 3⁄8-inch return line. The complete pass-through system looks as if it was factory-installed.

[27] The throttle body contains four vacuum ports for equipment and accessories. Three of the four are manifold vacuum sources, and Dave connected the power brake booster and PCV valve to the two larger ports at the rear. The single manifold source up front is used for the fuel-pressure regulator, and the lone ported source is used for the distributor vacuum-advance unit.

[28] The EZ-EFI throttle body contains a Holley-type throttle linkage, which is generally easy to work with. It accepts our Firebird’s original mechanical throttle linkage and return spring setup. Dave simply adjusted the throttle linkage so it provides full-throttle operation and clipped it into place.

[29] With the EFI system completely installed, Dave read through the instructions one last time to ensure that every component was installed properly, each electrical connection was tight, and the fuel connection was leak-free. The ECU requires a constant 12V supply, so FAST recommends connecting its main power and ground leads directly to the battery. (Be sure the charging system is completely up to task.) Dave routed each wire forward, where they connect to the appropriate terminal. Tune in next month for initial startup and performance testing!