It might seem that the intake manifold is one of the simplest components on an engine. After all, the purpose of the intake is to provide a series of passages to join the carburetor with the intake ports of the heads. That appears to be a fairly simple job description, and on the surface it is; but there is big power in just how those passages are connected. In a simple world, a design draftsman could just draw some straight lines between point A and point B, and lay out manifold with a series of corridors, using right angle turns to connect the plenum to the heads. In the old days, it’s surprising how many manifolds were designed just that way. Though those early intakes fulfilled their job description, they were found to be far from ideal -- and a great deal of potential power was needlessly left on the table.

It didn’t take long for enterprising hot-rodders to see the shortcomings in manifold design as applied to early OEM engines, and an industry was born. Aftermarket intake manifolds of widely varied design have been offered over the ensuing years -- some good, some decidedly poor, but all cast with the idea of improving on the efficiency of the factory designs in search of more horsepower. For traditional carbureted V-8 engines, the favored layout quickly evolved to the single four-barrel design. Driving this evolution was the development of larger capacity four-barrel carburetors, capable of handling the airflow requirements of all but the mightiest race engines. Popular contemporary four-barrel intake manifolds are typically offered in either single or dual-plane configurations. It’s worth a closer look to expand on the differences and applications here.

Single-Plane vs. Dual-Plane

In OEM carbureted applications, the two-plane design is overwhelmingly favored. Looking at a two-plane, with some runners crossing over from side to side, a two-level divided plenum, and the obviously greater complexity in casting such a piece, we have to ask why the manufacturers would go through the trouble. A single-plane open-plenum intake would obviously be easier to design and cheaper to build. Why bother with a two-plane? The reason is the design has many advantages.

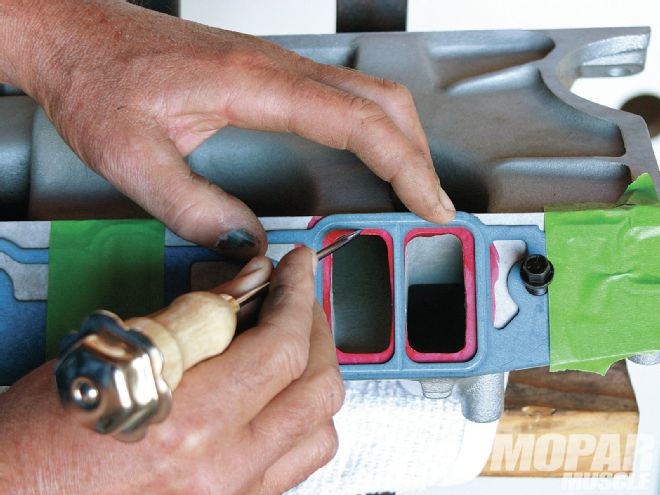

01 The simplest manifold mod is a port match, often called a gasket match since the port exits are carved to a standard gasket size. On the undersized Edelbrock Performer intake, the ports are significantly smaller than the head. In a hot small block, opening this intake to full port size provides a nice gain in flow and power."> <strong>01</strong> The simplest manifold mod is a port match, often called a gasket match since the port exits are carved to a standard gasket size. On the undersized Edelbrock Performer intake, the ports are significantly smaller than the head. In a hot small block, opening this intake to full port size provides a nice gain in flow and power.

<strong>01</strong> The simplest manifold mod is a port match, often called a gasket match since the port exits are carved to a standard gasket size. On the undersized Edelbrock Performer intake, the ports are significantly smaller than the head. In a hot small block, opening this intake to full port size provides a nice gain in flow and power.

As a general rule, it has been found that a two-plane intake improves low-rpm response, torque production, and idle quality. Runner length plays an important part in the rpm range at which an induction system “tunes-in,” taking advantage of the natural pressure wave pulses in the intake tract to provide a greater charge density in the cylinder, and therefore more torque and horsepower. As a general rule, longer runners “tune” at a lower rpm range, while shorter runners favor the upper end of the rpm band. Similarly, it has been found that a smaller plenum also favors power production lower in the rpm range, while larger plenums are more inclined to boost the top-end. In these two characteristics, the dual-plane has a natural advantage over the single-plane, but there is more. Runner cross-sectional area also plays a part. Smaller runners necessarily result in higher air-stream velocity in the manifold, which improves cylinder filling by improving inertia effect by virtue of the energy contained in the moving gasses. A dual-plane design generally features runners of a smaller average cross- sectional area than a single-plane, lending itself to higher low-speed velocity.

Taken as a group, smaller cross section, longer runners, and a smaller plenum create a system that is more responsive at transmitting the induction signal from the cylinder to the carburetor booster. This improvement in signal by the air stream connecting the cylinder to the carburetor improves the carburetor’s metering response, and aids in low-speed atomization, making the two-plane system well suited to low- and mid-range power productions and efficiency. Finally, there is the effect of pulse separation in a divided plenum two-plane intake. The induction cycle of any given cylinder of a V-8 engine will greatly overlap the induction cycle of the next cylinder in the firing order. The two-plane design isolates each side of the manifold, and connects the cylinders in a sequence in which each isolated plenum is connected to every other cylinder in the firing order. This way each side “sees” only every other firing pulse, every 180 degrees of crankshaft rotation. That’s why a dual-plane intake is often referred to as a 180-degree manifold. As a result, the induction pulse seen at the carburetor is greatly enhanced, especially at low air speed. This translates to further improved lower-rpm carburetor-booster function and atomization, resulting in better low-end output, enhanced drivability, and economy.

02 Manifold mods come down to porting, and the right tools are needed for the job. A high-speed die grinder is a must, and can be either air-powered or electric. Most of the metal work is done with carbide burrs, and when working intakes, the long shank carbides are a must."> <strong>02</strong> Manifold mods come down to porting, and the right tools are needed for the job. A high-speed die grinder is a must, and can be either air-powered or electric. Most of the metal work is done with carbide burrs, and when working intakes, the long shank carbides are a must.

<strong>02</strong> Manifold mods come down to porting, and the right tools are needed for the job. A high-speed die grinder is a must, and can be either air-powered or electric. Most of the metal work is done with carbide burrs, and when working intakes, the long shank carbides are a must.

While the advantages of a two-plane design are clear at lower rpm, compromises come into play at higher engine speeds. First, because the runners have to cross over from side to side, the manifold is arranged with upper and lower runners. Since there is only so much height that can be practically engineered into the manifold, if it’s going to fit under the hood, the upper runners generally have a nice straight approach into the heads port, while the lower runners aren’t usually as fortunate. Second, the smaller divided plenum provides less volume for the engine to draw from as the rpm increases. However, many of these potential pitfalls of the two-plane can be greatly overcome with increased manifold height and well laid out runner and plenum designs. Ever hear of “high-riser” intakes?

A single-plane is a much simpler looking design than a 180-degree manifold, and with its nearly straight-shot runners, it sure looks to have more power potential. Just by its basic layout, it’s far easier to achieve a more equal port flow distribution with a single-plane design. As rpm and airflow demands increase, the direct runners of a single-plane are about as good as it gets for moving air/fuel mixture from the carburetor to the head’s ports. A well designed single-plane intake will have an inherent advantage over a two-plane design in ultimate airflow capacity, without the compromises in airflow distribution typically found between the high and low runners of a dual-plane. The single-plane is an ideal configuration for a great race or high-rpm intake manifold type, with the shorter runners naturally tuning at a higher rpm.

Manifold Mods

While an aftermarket intake manifold appropriately matched to the application and rpm range of an engine will typically result in a substantial power improvement, modifications can take things to the next level. The most basic of these mods is a simple port match to the intake runners of the cylinder head. This ensures a smooth transition at the junction with the cylinder heads, and is typically accomplished by matching both the intake port and the runner exits of the manifolds to a standard gasket size. The value of a port match job depends upon the parts combination in question. Power gains can be significant if you are dealing with restricted smaller sized ports in an engine application hungry for airflow.

03 A beginner’s mistake is to simply flare the port out right at the exit when gasket matching. The right way to do the job is to blend the cuts well down the manifold runners."> <strong>03</strong> A beginner’s mistake is to simply flare the port out right at the exit when gasket matching. The right way to do the job is to blend the cuts well down the manifold runners.

04 Two-plane intake manifolds are usually the best choice for a street application where a broader power curve is important. A state-of-the-art two-plane such as the AirGap from Edelbrock will offer substantially more torque without giving much up at the top of the power band.">

<strong>03</strong> A beginner’s mistake is to simply flare the port out right at the exit when gasket matching. The right way to do the job is to blend the cuts well down the manifold runners.

04 Two-plane intake manifolds are usually the best choice for a street application where a broader power curve is important. A state-of-the-art two-plane such as the AirGap from Edelbrock will offer substantially more torque without giving much up at the top of the power band.">

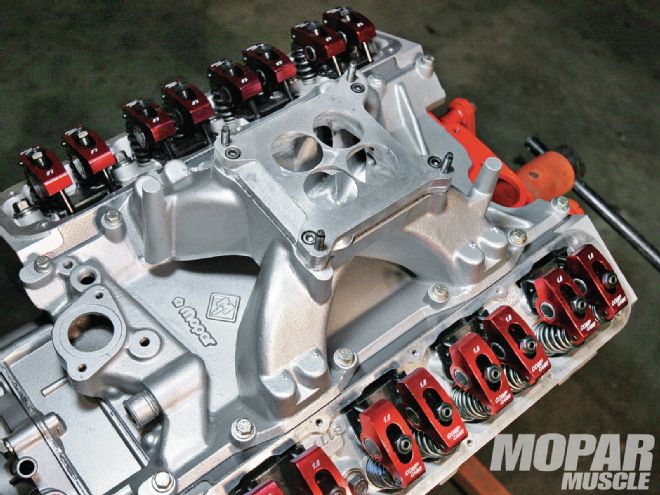

<strong>04</strong> Two-plane intake manifolds are usually the best choice for a street application where a broader power curve is important. A state-of-the-art two-plane such as the AirGap from Edelbrock will offer substantially more torque without giving much up at the top of the power band.

05 A single-plane intake definitely has a racier look, as this Mopar Performance M1 unit demonstrates. In a higher output, race, or stroker applications, the airflow becomes more critical, and a single-plane’s higher top-end power advantage can be a worthwhile trade.">

<strong>04</strong> Two-plane intake manifolds are usually the best choice for a street application where a broader power curve is important. A state-of-the-art two-plane such as the AirGap from Edelbrock will offer substantially more torque without giving much up at the top of the power band.

05 A single-plane intake definitely has a racier look, as this Mopar Performance M1 unit demonstrates. In a higher output, race, or stroker applications, the airflow becomes more critical, and a single-plane’s higher top-end power advantage can be a worthwhile trade.">

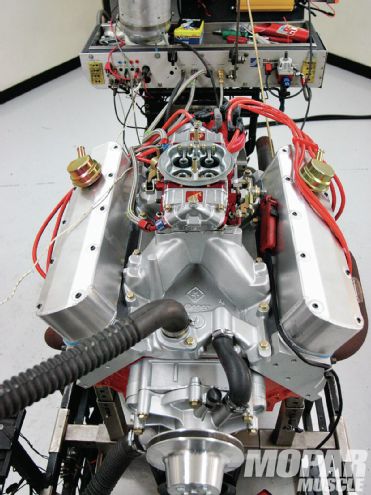

<strong>05</strong> A single-plane intake definitely has a racier look, as this Mopar Performance M1 unit demonstrates. In a higher output, race, or stroker applications, the airflow becomes more critical, and a single-plane’s higher top-end power advantage can be a worthwhile trade.

<strong>05</strong> A single-plane intake definitely has a racier look, as this Mopar Performance M1 unit demonstrates. In a higher output, race, or stroker applications, the airflow becomes more critical, and a single-plane’s higher top-end power advantage can be a worthwhile trade.

It does not take a lot of specialized equipment to port match, just a die grinder and an appropriate carbide cutter. The actual process begins by marking the manifold for a cut line using the gasket as a template. Once marked, there is nothing left to do but start cutting. The key to an effective job here is to blend the work properly into the port. The idea is to create a seamless transition from the gasket line into the port runner, and not to simply flare the port out to the cut-lines at the flange. On the dyno, we have seen 8-10 horsepower gains given a proper port match on a standard Edelbrock Performer intake to the full 340/360 gasket size.

From the basic port-matching modification described above, the sky is the limit on further intake porting. This can be as basic as a mild clean-up of the runner’s casting irregularities, to full-on flow bench porting. Consider the complete engine as a flow system and it becomes clear that the pathway does not begin and end at the cylinder head. Bolt an intake manifold to a fully-prepped cylinder head and the two become one as far as airflow is concerned. Most guys like to take it for granted that most any aftermarket intake manifold will be more than up for the job, and it can be—but not always. Sometimes the intake flow is not even close, and in most cases there is room for improvement, especially in high-powered applications where the heads are set to kill. Here is where a fully ported manifold work can up the power numbers.

06 More dramatic manifold mods start at the plenum, usually cutting a nice radius at the runners’ roof transitions, and reworking the runners where they open to the plenum. This is often where the most flow is found when modifying an intake."> <strong>06</strong> More dramatic manifold mods start at the plenum, usually cutting a nice radius at the runners’ roof transitions, and reworking the runners where they open to the plenum. This is often where the most flow is found when modifying an intake.

<strong>06</strong> More dramatic manifold mods start at the plenum, usually cutting a nice radius at the runners’ roof transitions, and reworking the runners where they open to the plenum. This is often where the most flow is found when modifying an intake.

Generally, major manifold porting begins at the plenum, with the key areas being the roof transition from the carburetor flange into the tops of the runner entries. This area has a significant effect on flow into the runner, and the typical form is to create a nice gentle rolled radius. Another area of attention is at the runners’ junction with the plenum, with some favoring a bull-nosed radius, while others work to a knife edge. The idea is to improve the transition into the runner and produce a more uniform cross-sectional area and, ultimately, airflow through the runners. While these are the most critical areas to manifold porting, sometimes the runners themselves are subjected to considerable rework, sometimes to enlarge, and always to streamline for more flow—just like porting a head. Also like head porting, different intake manifold designs have their own peculiarities. At the higher levels of manifold porting, a flow bench is an indispensible tool. Considerations beyond raw flow include the airflow distribution, manifold cross section and tapper, and wet flow which can influence fuel distribution.

Obviously some of these considerations are not the kinds of things most guys can address with a grinder in their garage, but at the professional level of manifold porting, these items are essential. That said, an enthusiast taking a common sense approach to manifold porting can generally improve a typical aftermarket manifold casting.

07 With serious intake modifications comes the need to validate the changes and quantify the results. Serious flow development will require the aid of a flow bench. Each runner is tested individually, and it is surprising how much they can vary with some intake designs."> <strong>07</strong> With serious intake modifications comes the need to validate the changes and quantify the results. Serious flow development will require the aid of a flow bench. Each runner is tested individually, and it is surprising how much they can vary with some intake designs.

<strong>07</strong> With serious intake modifications comes the need to validate the changes and quantify the results. Serious flow development will require the aid of a flow bench. Each runner is tested individually, and it is surprising how much they can vary with some intake designs.

On The Dyno: Single-Plane vs. Dual-Plane

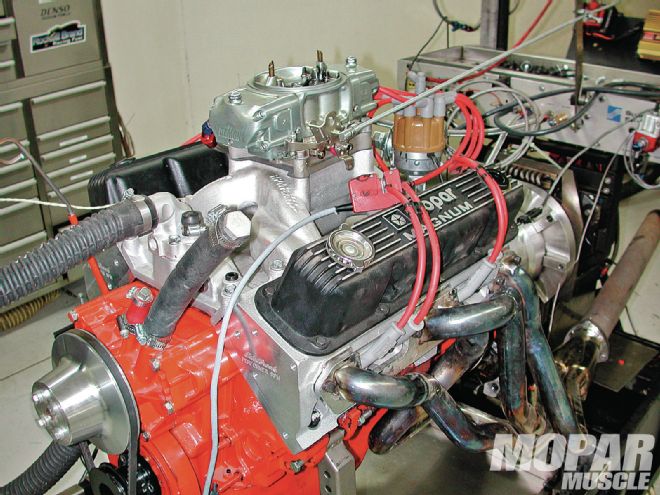

As much as the lower-rpm advantages of a dual-plane are discussed, we find many enthusiasts seem to refuse to believe it. Sure, in a high-rpm, or race application, the single-plane is going to have an advantage. Often such an installation will come with a high-stall converter in the transmission that will make the lower end of the rpm range even less relevant. However, in a typical street performance application, a good dual-plane like Edelbrock’s RPM AirGap will be a much better choice. To illustrate, we ran a typical street style 360 Magnum on the dyno, with both an AirGap dual-plane and an M1 single-plane. The results of our little test were typical of what we see over and over in these applications, where a single-plane is substituted for a well-designed two-plane—a tremendous amount of torque given up in the low- to mid-range for a small gain up top in peak power. If it's just the bragging rights of a higher peak power number that you are after, the single-plane delivers. For tire-smoking torque and far more average power over the full rpm range, the AirGap rules.

Our test engine is an old Mopar Performance Magnum 300 horsepower crate engine that has been modified to a hot street performance spec. The engine features box stock Edelbrock Magnum heads, and a custom Comp Cams hydraulic roller cam speccing out to 224/230-degrees duration at .050, with .573/.568-inch lift via a set of Comp "Magnum” stud mounted 1.6:1 ratio rockers. It is a pretty simple combination, but with the upgraded heads and cam combination, it represents a hot street 360. The numbers really tell the tale of which intake is the better choice.

08 Fully ported, this small-block Victor intake manifold’s flow increased from the 260-270 cfm range to move 370-380 cfm—enough to handle a serious small-block head. That kind of dramatic increase is the result of professional flow work, in this case from the crew at Dr J’s Performance. "> <strong>08</strong> Fully ported, this small-block Victor intake manifold’s flow increased from the 260-270 cfm range to move 370-380 cfm—enough to handle a serious small-block head. That kind of dramatic increase is the result of professional flow work, in this case from the crew at Dr J’s Performance.

<strong>08</strong> Fully ported, this small-block Victor intake manifold’s flow increased from the 260-270 cfm range to move 370-380 cfm—enough to handle a serious small-block head. That kind of dramatic increase is the result of professional flow work, in this case from the crew at Dr J’s Performance.

Manifold Porting: What’s it Worth?

When considering porting an intake manifold, the first question that needs to be answered is Do you really need it? For a mild combination with production style heads, an out-of-the-box installation or a simple port match will probably do just fine. However, if the combo is seriously stepped up and the cylinder head moves big volumes of air, the intake manifold might become the bottleneck. In this situation, a well ported intake can pay surprising dividends in power. With the broader availability of serious cylinder heads for Mopar wedge and small-block engines, manifold porting is more relevant than ever before. We put together a stout 408 Magnum stroker, and with max ported Edelbrock heads, the intake flow was an issue. In this case we were running an M1 single-plane intake, and on the bench, the head flow exceeded that of the manifold. We have found through numerous flow and dyno tests that the manifold flow should exceed that of the peak intake port flow for best power.

We flow tested all eight ports of the M1 intake and found it to be better than many we have tested in terms of relatively even port flow distribution, with the best port flowing 296 cfm and the worst recording 289. Fully ported, the intake delivered airflow in the 320-cfm range, more than enough to keep up with our modified cylinder heads. These kinds of flow improvements take considerable expertise, and benefit from flow bench development, but illustrate the kinds of gains that can be achieved. We have seen even more dramatic increases with manifolds of a poorer design than this Mopar Performance unit, often with the flow distribution dramatically improved.

09 A well matched combination considers the entire engine package and its intended application. This Magnum stroker features fully ported heads and an intake that can keep up to make over 550 horsepower in street pump-gas trim."> <strong>09</strong> A well matched combination considers the entire engine package and its intended application. This Magnum stroker features fully ported heads and an intake that can keep up to make over 550 horsepower in street pump-gas trim.

10 To illustrate the typical difference between a single-plane and dual-plane manifold in a street performance application, we ran this modified 360 Magnum on the dyno to quantify the effect on the power curve. The baseline intake is the Edelbrock AirGap, the benchmark for dual-plane performance.">

<strong>09</strong> A well matched combination considers the entire engine package and its intended application. This Magnum stroker features fully ported heads and an intake that can keep up to make over 550 horsepower in street pump-gas trim.

10 To illustrate the typical difference between a single-plane and dual-plane manifold in a street performance application, we ran this modified 360 Magnum on the dyno to quantify the effect on the power curve. The baseline intake is the Edelbrock AirGap, the benchmark for dual-plane performance.">

<strong>10</strong> To illustrate the typical difference between a single-plane and dual-plane manifold in a street performance application, we ran this modified 360 Magnum on the dyno to quantify the effect on the power curve. The baseline intake is the Edelbrock AirGap, the benchmark for dual-plane performance.

11 We swapped to a box-stock Mopar Performance M1 single-plane, a very good single-plane design for the Mopar small-block. The single-plane did pick up some power up top, but the loss in torque was dramatic.">

<strong>10</strong> To illustrate the typical difference between a single-plane and dual-plane manifold in a street performance application, we ran this modified 360 Magnum on the dyno to quantify the effect on the power curve. The baseline intake is the Edelbrock AirGap, the benchmark for dual-plane performance.

11 We swapped to a box-stock Mopar Performance M1 single-plane, a very good single-plane design for the Mopar small-block. The single-plane did pick up some power up top, but the loss in torque was dramatic.">

<strong>11</strong> We swapped to a box-stock Mopar Performance M1 single-plane, a very good single-plane design for the Mopar small-block. The single-plane did pick up some power up top, but the loss in torque was dramatic.

<strong>11</strong> We swapped to a box-stock Mopar Performance M1 single-plane, a very good single-plane design for the Mopar small-block. The single-plane did pick up some power up top, but the loss in torque was dramatic.

Dyno Results Mopar 360 Magnum Small-Block Tested at Westech Performance Group RPM Dual-Plane TQ Single-Plane TQ Dual-Plane HP Single-Plane HP 3,000 403.0 371.7 230 212 3,100 417.5 377.4 246 223 3,200 425.4 388.8 259 237 3,300 428.5 394.5 269 248 3,400 430.5 397.1 279 257 3,500 432.7 396.8 288 264 3,600 432.8 398.3 297 273 3,700 433.9 395.8 306 279 3,800 434.5 392.8 314 284 3,900 438.9 392.0 326 291 4,000 440.3 394.7 335 301 4,100 440.9 399.4 344 312 4,200 445.0 414.5 356 331 4,300 447.3 421.2 366 345 4,400 446.4 428.0 374 359 4,500 443.9 425.4 380 365 4,600 442.3 426.6 387 374 4,700 440.8 423.7 394 379 4,800 440.3 422.7 402 386 4,900 436.3 425.8 407 397 5,000 431.7 425.9 411 405 5,100 424.0 422.9 412 411 5,200 416.9 421.9 413 418 5,300 411.2 418.4 415 422 5,400 406.1 414.4 418 426 5,500 400.6 407.7 419 427 5,600 392.7 401.1 419 428 5,700 386.7 394.4 420 428 5,800 380.0 386.8 420 427 5,900 372.9 374.5 419 421 6,000 358.5 359.1 410 410

Manifold Flow Test Mopar M-1 Single-Plane Intake Stock vs. Fully Ported SuperFlow 600 Flowbench CFM at 28-Inches Water Depression Ported By Dr J’s Performance RUNNER STOCK Ported 1 291 326 2 291 317 3 289 317 4 294 323 5 296 321 6 287 335 7 290 320 8 289 325