DCI’s Don Johnston installs a set of shaft-mounted rocker arms on his high-performance 455 to cure valvetrain-instability issues

DCI’s Don Johnston installs a set of shaft-mounted rocker arms on his high-performance 455 to cure valvetrain-instability issues

An engine that just doesn't perform as it should at high speed on the dyno or racetrack can induce a series of checks that usually first includes measuring the pressure and volume of the fuel being delivered to the carburetor. If that's ruled out, then the valvetrain is generally suspected next. It's comprised of many components working together to transfer camshaft lobe profile into valve lift, and its weakest link can compromise the functionality and performance of any engine.

Valve float is a serious valvetrain malady that occurs when the valves bounce on their seats, preventing the engine from building cylinder pressure at higher rpm. In a hydraulic cammed engine, it's typically the result of insufficient lifter-bleed rate. It generally occurs in a solid-cammed engine if valvesprings with insufficient pressure are used or when proper-spec units weaken over time. In either instance, it sends a shockwave throughout the entire valvetrain that can cause significant component damage, and ultimately complete engine failure.

When dealing with high-pressure valvesprings like those required with an aggressive solid-roller cam, high-quality units generally don't lose pressure quickly or erratically under normal use. If the rocker arms are flexing under load, however, the instability and inconsistent operation can prematurely wear valvesprings, which ultimately leads to valve float. Follow along as we discover this very occurrence in this high-performance 455 and put an end to rocker arm flex for good.

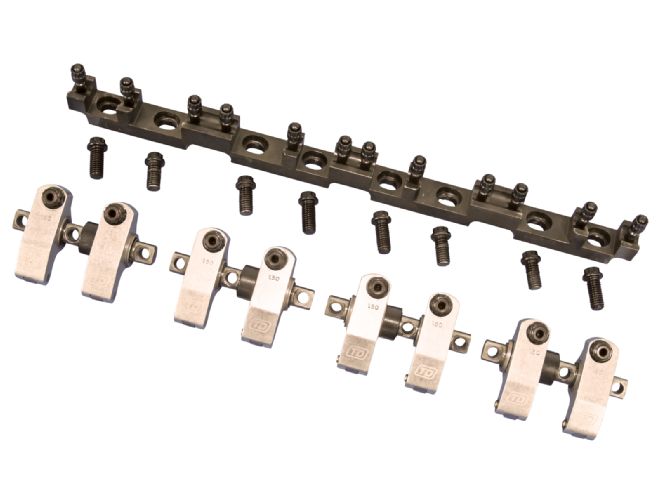

1 A shaft-mounted rocker system eliminates the flexing and instability associated with stud-mounted rocker arms in extreme applications. While certainly not required for every Pontiac, those with high-pressure valvesprings and aggressive camshafts can often benefit from it. T&D Machine Products has been producing Pontiac V-8 shaft-rocker systems for more than 20 years, and they’re among the very best available today. Pricing starts at $1,225.

1 A shaft-mounted rocker system eliminates the flexing and instability associated with stud-mounted rocker arms in extreme applications. While certainly not required for every Pontiac, those with high-pressure valvesprings and aggressive camshafts can often benefit from it. T&D Machine Products has been producing Pontiac V-8 shaft-rocker systems for more than 20 years, and they’re among the very best available today. Pricing starts at $1,225.

DCI's 455

Don Johnston opened DCI Automotive & Motorsports (DCI) in 1981, specializing in carburetor rebuilds and modifications. It is now located in Atwater, Ohio. He began building Pontiacs in 1983 and takes extracting stout performance from our beloved mill very seriously.

Considered quite capable by many knowledgeable hobbyists, he honed that reputation when he competed in the 2009 Engine Master's Challenge with a Pontiac 455. Today that very engine powers Don's personal race car.

It consists of a stock-bore 455 block that's filled with a 4.21-inch, factory N-crank; 6.80-inch Eagle H-beam connecting rods; and Ross custom pistons. It's topped by a pair of Edelbrock Performer RPM cylinder heads that flow 367 cfm with a standard intake port arrangement and produces a pump-gas–friendly compression ratio of 9.3:1. A Victor intake manifold and a 1,000-cfm Quick Fuel carburetor feeds the engine, while a solid-roller camshaft actuates the valve-train to the tune of 260/266 degrees of 0.050-inch duration and 0.630-inch valve lift. At a race weight of 2,550 pounds, the 455-inch mill has propelled Don's tube-chassis Pontiac to a quickest quarter-mile e.t. of 8.90 seconds with a terminal speed of 152 mph.

"We noticed e.t. starting to go away toward the end of the season," says Don. "So we pulled the engine to freshen it up over the offseason. We planned to measure its output on the dyno before and after the freshening to gauge how much we gained from our efforts."

During the initial dyno session, Don found that the 455 simply wouldn't pull past 5,000 rpm. "We knew it was capable of running to at least 6,300 rpm as it had on the race track. Based on the amount of torque it generated during the dyno pull, we were confident it should be making great horsepower, but something was holding it back. It obviously wasn't fuel related, so my guess was valvetrain instability. We stopped testing and began inspecting for anything out of the ordinary."

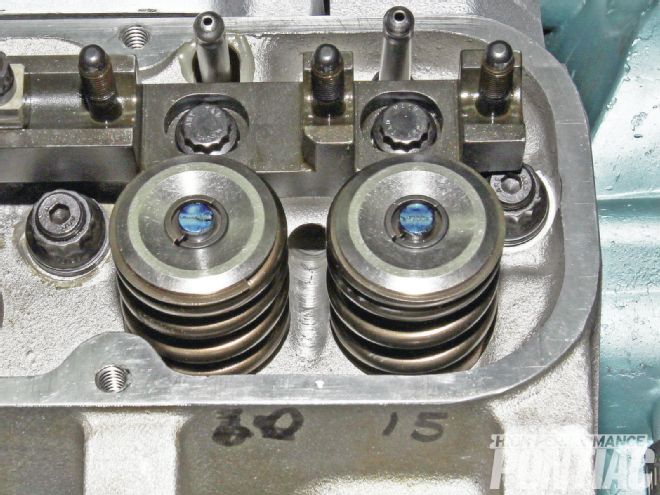

Don confirmed his suspicions when he discovered a significant amount of abnormal wear on several valve-stem tips and the roller wheels of several lifters. He also found that the valvesprings, which initially measured at 220 pounds on the seat, had slipped to as little as 160 to 180 psi. "When any valvetrain component fails, it usually takes out others and that can cause catastrophic engine damage. We were lucky that we caught this before anything broke," he adds.

2 The process begins by completely removing the existing stud-mounted rocker arms and associated hardware. He uses a 5⁄8-inch wrench to loosen and remove each positive-locking nut, and the rocker arm lifts away.

2 The process begins by completely removing the existing stud-mounted rocker arms and associated hardware. He uses a 5⁄8-inch wrench to loosen and remove each positive-locking nut, and the rocker arm lifts away.

The studs and rocker arms of a stud-mounted assembly can, and often do flex when exposed to very high valve lift and/or spring pressure, especially at high engine operating speed. This very condition is likely what lead to the issues Don found in his engine. A popular option to quell rocker-stud flex is the addition of a valvetrain stabilizer (also called a stud girdle). It generally consists of a piece of machined aluminum that's clamped to a set of special, positive-locking nuts on a bank of rocker arms, improving rigidity and geometry.

While effective in some instances, stud girdles sometimes require the use of taller-than-stock valve covers and can make setting and maintaining valve lash a cumbersome task. Don adds, "We've found that it just doesn't help stability much in our engines. In fact, we've seen it break rocker studs. In my opinion, the best solution for a race engine is a shaft-mounted rocker system like that from T&D. We've used them successfully a number of times in the past and think they're a good value for the cost."

T&D Machine Products

Larry Tores of T&D Machine Products in Carson City, Nevada, developed a shaft-mounted roller-rocker-arm system to address valvetrain instability issues in his small-block-Chevy–powered race car in the mid-'70s. "It worked exceptionally well," says T&D's Phil Elliott. "We introduced our first mass-produced rocker system for the Buick V-6 during the '80s. That quickly expanded into offerings for other makes, including Pontiac."

A typical T&D rocker arm is machined from 2024-alloy aluminum. It features a low-mass design that lessens the amount of spring pressure required to control the valvetrain, while remaining very rigid and strong to maximize stability and durability. It features internal oil passages that serve to lubricate the roller bearings in the fulcrum and tip. It rides on a 0.625-inch-diameter main shaft that's constructed of 8620-alloy steel, and heat-treated for maximum durability. Each shaft contains a pair of rockers, which are then fastened to a steel shaft stand that bolts directly to the cylinder head.

Available rocker-arm ratios range from 1.50:1 to 1.80:1. Depending upon the application, the rocker-arm pushrod cup can be located in the stock position or with a specific offset to clear extra-wide intake ports. Other ratios are available on a custom order basis. T&D notes that it can easily accommodate different ratios for intake and exhaust, for those who might prefer 1.65 on the intake and only 1.5 on the exhaust, for instance.

Several options are also available. That includes roller-tip needle bearings, lighter-weight rocker-arm bodies, and rocker-arm bodies constructed of proprietary steel for maximum durability. "Another popular option is our spring oil hole. It consists of a 0.040-inch orifice that's drilled through the rocker body, and sprays pressurized oil directly onto the valvesprings to cool and lubricate them. We've found it can reduce the operating temperature of a valvespring by as much as 50 degrees, potentially adding to its service life," adds Elliott.

T&D produces rocker systems for a number of cylinder heads that fit the Pontiac block. That includes original cast-iron units. as well as the offerings from Edelbrock, Roland Racing, and Wenzler. Pricing for a typical T&D set like that to fit Johnston's Edelbrock heads starts at $1,225. It includes all of the necessary components and hardware for easy and complete installation.

T&D rocker systems are available through speed shops, engine builders, or directly from the manufacturer. "We sell duplicate sets to large retailers, and they work out well for fairly standard applications. But we've found that most sets we ship are customized in some way to fit very specific applications. That makes it very difficult to sell an off-the-shelf set that fits all applications without some sort of modification," says Elliott.

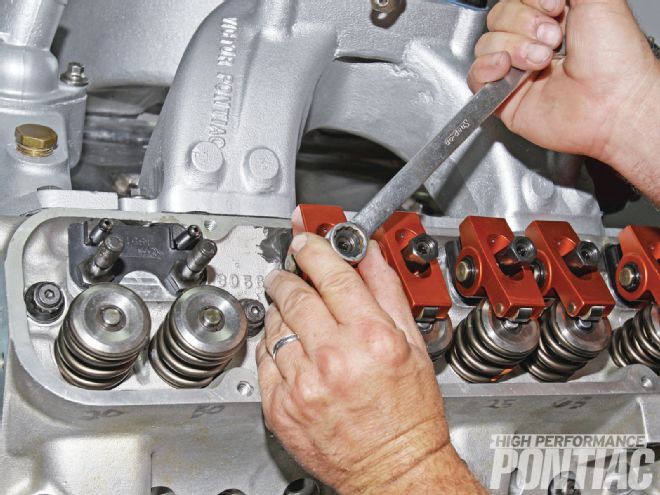

The Purchase and Install

Upon discovering the evidence in his 455, Don contacted T&D to order a shaft-mounted rocker system to replace the stud-mounted roller rockers he had been using. He provided T&D with a number of critical details and measurements; in about six weeks the set arrived on his doorstep. Don began the installation process of new valvesprings and the shaft-mounted rocker system with new pushrods, and within a few hours it was complete. He's confident he has permanently cured his 455 of any valvetrain stability issues otherwise created by stud-mounted rockers.

We asked at what point he feels upgrading to a shaft-mounted rocker system is required. "When building our engines, we feel it becomes necessary whenever valvespring seat pressure exceeds 200 psi, the engine will consistently operate at or above 6,000 rpm, and/or when using an aggressive solid roller with more than 0.630-inch lift. This engine was on the cusp, and it proved that the factory-type stud-mounted design wasn't effective enough."

The cost for high-quality rocker arms and all associated hardware is generally only a few hundred less than the starting price for a T&D shaft system. Don considers it cheap insurance in an engine that's raced regularly. T&D offers a complete rebuild service to restore the functionality of a single piece or the entire set, which fortifies its position as a long-term investment for your Pontiac.

Neither company recommends running a T&D shaft-mounted rocker system on a dedicated street engine, but both are aware that customers do just that.

"No matter how good the quality, when exposed to continuous heating and cooling cycles, any aluminum rocker arm, whether stud- or shaft-mounted, will fatigue over time," cautions Don. "We recommend checking them after every 2,000 miles on the street and suggest immediately replacing any that look suspect."

Conclusion

Though Don's 455 hasn't been back to the dyno since the addition of the T&D rocker system, new valvesprings, and new pushrods, the expected power gains will be directly related to improved valvetrain stability, allowing the engine to reach its full performance potential. So if extracting every last horsepower is important or you have reason to suspect valvetrain instability, then a rocker-shaft system like that from T&D might be a wise investment for your Pontiac!

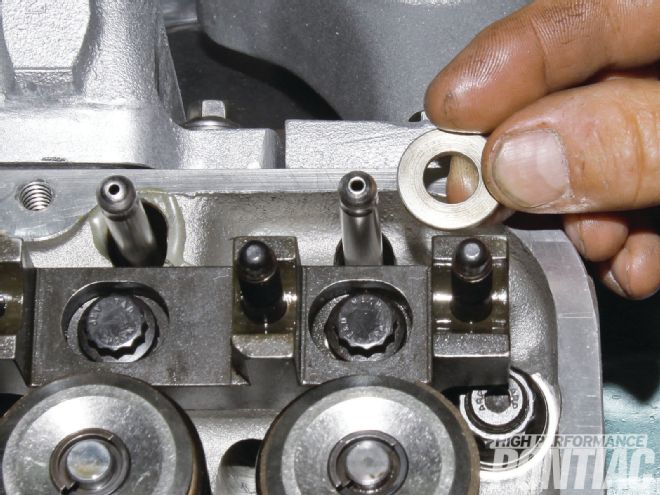

Attaining Proper Valvetrain Geometry

Proper valvetrain alignment places the rocker tip in the center of the valve-stem tip throughout the entire opening and closing event. Unlike in a stud-mounted rocker assembly in which pushrod length is largely responsible for attaining precise alignment, a shaft-mounted rocker arm assembly requires a combination of appropriate shimming and specific pushrod length to achieve the ideal position. T&D supplies a number of shims in varying thicknesses with its shaft-mounted rocker system. It allows the installer to properly adjust shaft-stand height to attain perfect alignment whether the valve is opened or closed.

Determining ideal shaft-stand height generally occurs during pre-assembly, and includes installing a cylinder head and gasket onto the block, and torquing the head bolts to the correct specifications in an attempt to best replicate normal operating conditions. A lightweight test spring is used in place of the normal-tension valvespring. Once the required stand shims are installed to properly position the rocker tip's roller wheel on the valve stem, an adjustable pushrod (or pushrod-length checker) is used to determine the appropriate length to achieve ideal alignment at all lift points.

Johnston says this process could be performed with the engine assembled and normal valvesprings installed, but it's unlikely that an adjustable pushrod could withstand the pressure required when running an aggressive solid-roller cam. It would likely deform or collapse under load. If you find yourself in this situation and installing a test spring isn't possible, having a large assortment of custom-length pushrods on-hand is the best solution to find which works best for your application.